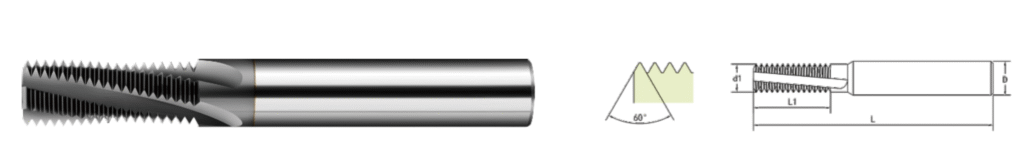

BSPP(G) Multi-Form 55 degree Thread Mill | Solid Carbide Thread Milling Cutter

Explore solid carbide multi-form thread milling cutters for precise internal and external 55° BSP threads.

- Thread milling pipe threads capability enhanced by a precision-engineered 55 degree thread mill.

- Available in uncoated, AlTiN, TiAlN, and DLC coatings.

- Supports both right-hand and left-hand threads.

- High performance thread mill bit at competitive prices.

Overview

The G Multi-Form Thread Mill is a solid carbide thread milling cutter designed for machining parallel pipe threads with high accuracy and efficiency. Globally, G threads are also referred to as:

BSPP (British Standard Pipe Parallel)

PF Thread (Japan JIS Standard)

ISO 228 Parallel Pipe Thread

Thanks to its full-profile cutting design, this tool can process internal and external threads, in both left-hand and right-hand directions, with consistent precision. It is a reliable solution for industries that require tight tolerance pipe connections such as aerospace, automotive, oil & gas, hydraulics, and general machinery.

Applications

The G Multi-Form Thread Mill is widely used in:

Aerospace: hydraulic fittings, fuel systems

Automotive: engine and transmission components

Oil & Gas: threaded pipe joints, valves

General Engineering: machinery, pumps, pneumatics

Why Choose a Multi-Form Thread Mill?

Universal compatibility with G / BSPP / PF / ISO 228 standards

Solid tungsten carbide for durability and long tool life

Multi-form geometry for one-pass threading with superior accuracy

CNC optimized – suitable for high-speed, high-precision machining

Adaptable to different materials through specialized coatings

Capable of left-hand, right-hand, internal, and external threads

How to Choose a Carbide Thread Mill?

Material & Coating Recommendations

| Material | Recommended Coating | Benefits |

|---|---|---|

| Copper & Aluminum | TiB₂ / DLC / no coating | Prevents built-up edge, smooth chip evacuation |

| 45# Steel / Carbon Steel | TiN / TiCN | Cost-effective, reduces wear |

| Stainless Steel | TiAlN / AlCrN | High heat resistance, prevents galling |

| P20 Tool Steel | TiAlN / AlTiN | Long life in tough tool steels |

| Cast Iron | TiN / TiAlN | Excellent wear resistance, stable cutting |

| Titanium Alloys | AlTiN / TiAlSiN | Withstands high temperatures, prevents chipping |

| Heat-Resistant Alloys | AlCrN / TiAlSiN | Superior oxidation resistance |

Choosing the right coating is one of the key factors that influence machining performance, tool life, and surface finish.

Single-Form vs. Multi-Form Thread Mills

When selecting a thread milling tool, both single-tooth (single point) and full-form thread mills are available:

| Type | Advantages | Limitations |

|---|---|---|

| Single-Form |

|

|

| Multi-Form |

|

|

At our Minnexon, we can supply both single-form and multi-form thread mills, ensuring you always have the right solution for your production needs.

Technical Specifications (Customizable)

| BSPP/G | TPI | Pitch | d1/mm | L1/mm | D/mm | L/mm | Flutes | Drill dia./mm | Unit Price/USD |

|---|---|---|---|---|---|---|---|---|---|

| G1/16-28 | 28 | 0.907 | 5.8 | 17 | 6 | 60 | 3 | 6.7 | US$74.00 |

| G1/8-28 | 28 | 0.907 | 7.7 | 20 | 8 | 60 | 4 | 8.7 | US$108.00 |

| G1/4-19 | 19 | 1.337 | 9.9 | 27 | 10 | 75 | 4 | 11.8 | US$132.00 |

| G3/8-19 | 19 | 1.337 | 11.9 | 26.7 | 12 | 75 | 4 | 15.2 | US$166.00 |

| G1/2-14&G3/4-14 | 14 | 1.814 | 11.9 | 30 | 12 | 75 | 4 | 19 | US$166.00 |

| G1/2-14&G3/4-14 | 14 | 1.814 | 11.9 | 35 | 12 | 83 | 4 | 19 | US$166.00 |

| G1/2-14&G3/4-14 | 14 | 1.814 | 15.7 | 40 | 16 | 100 | 5 | 19 | US$304.00 |

| G1-11 | 11 | 2.309 | 16 | 42 | 16 | 100 | 5 | 30.7 | US$304.00 |

| G2-11 | 11 | 2.309 | 19.9 | 42 | 20 | 100 | 5 | 30.7 | US$388.00 |

How to Choose a Carbide Thread Mill

- Choose the right carbide thread mill for better performance.

- Select a proper coating to match the material. TiAlN or AlCrN works well for steel. Use TiCN for aluminum or copper.

- Pick single-tooth cutters for small holes or fine threads.

- Choose three-tooth or full-tooth cutters for higher speed and large threads.

- Check the helix angle and cutting direction.

- Use a positive rake for soft materials and a neutral rake for hard materials.

- Always confirm tool diameter, pitch, and thread depth.

- Right choice means longer tool life and cleaner threads.

Related products

-

NPTF Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

NPT Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

BSPP/BSPT Single-Form 55 Degree Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

BSPT Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more

Get in Touch

We will provide you with feedback within 24 hours.