Metric Solid Carbide Straight Flute Tap

- Material: Premium Micro-grain Solid Carbide (Not HSS) for extreme wear resistance.

- Performance: Delivers 3x-5x faster cutting speeds & superior rigidity compared to High-Speed Steel.

- Geometry: Straight Flute design (DIN Standard) optimized for short-chipping stability.

Metric Solid Carbide Straight Flute Taps

Precision Engineering for High-Performance Threading

At Minnexon, we specialize in advanced threading solutions. Our Metric Solid Carbide Straight Flute Taps are engineered to deliver superior precision, rigidity, and tool life. Unlike standard market options, Minnexon taps are manufactured from premium micro-grain Tungsten Carbide, designed to handle the most demanding industrial applications where accuracy and speed are non-negotiable.

Technical Specifications (Customizable)

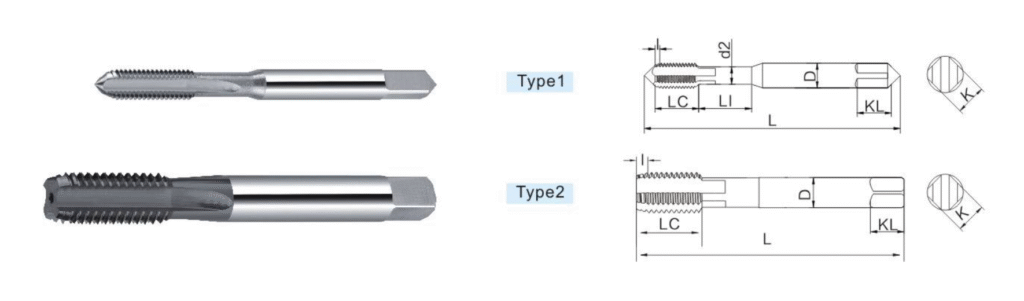

| Thread Size | I | L | LC | D | Flute | KL | K | L1 | d2 |

|---|---|---|---|---|---|---|---|---|---|

| M1.4×0.3 | 2P | 42 | 6 | 3 | 3 | 5 | 2.5 | ||

| M1.6×0.35 | 2P | 42 | 8 | 3 | 3 | 5 | 2.5 | ||

| M1.7×0.35 | 2P | 42 | 8 | 3 | 3 | 5 | 2.5 | ||

| M1.8×0.35 | 2P | 42 | 9 | 3 | 3 | 5 | 2.5 | ||

| M2.0×0.4 | 2P | 42 | 10 | 3 | 3 | 5 | 2.5 | ||

| M2.5×0.45 | 2P | 42 | 11 | 3 | 3 | 5 | 2.5 | ||

| M3.0×0.5 | 2P | 52 | 11 | 4 | 3 | 6 | 3.2 | 6 | 2.4 |

| M3.5×0.6 | 2P | 52 | 12 | 4 | 3 | 6 | 3.2 | 7 | 2.8 |

| M4.0×0.7 | 2P | 55 | 13 | 5 | 3 | 7 | 4 | 7 | 3.1 |

| M5.0×0.8 | 2P | 60 | 15 | 5 | 3 | 7 | 4 | 10 | 4 |

| M6.0×1 | 2.5P | 65 | 16 | 6 | 3 | 7 | 4.5 | 10 | 4.8 |

| M8.0×1 | 2.5P | 73 | 18 | 6.2 | 4 | 8 | 5 | ||

| M8.0×1.25 | 2.5P | 73 | 18 | 6.2 | 4 | 8 | 5 | ||

| M10×1 | 2.5P | 75 | 21 | 8 | 4 | 9 | 6 | ||

| M10×1.25 | 2.5P | 75 | 21 | 8 | 4 | 9 | 6 | ||

| M10×1.5 | 2.5P | 75 | 21 | 8 | 4 | 9 | 6 | ||

| M12×1.0 | 2.5P | 83 | 25 | 9 | 4 | 9 | 7 | ||

| M12×1.25 | 2.5P | 83 | 25 | 9 | 4 | 9 | 7 | ||

| M12×1.5 | 2.5P | 83 | 25 | 9 | 4 | 9 | 7 | ||

| M12×1.75 | 2.5P | 83 | 25 | 9 | 4 | 9 | 7 | ||

| M14×1.5 | 2.5P | 90 | 26 | 10.5 | 4 | 11 | 8 | ||

| M14×2 | 2.5P | 90 | 26 | 10.5 | 4 | 11 | 8 | ||

| M16×1.5 | 2.5P | 98 | 29 | 12.5 | 4 | 13 | 10 | ||

| M16×2 | 2.5P | 98 | 29 | 12.5 | 4 | 13 | 10 | ||

| M18×1.5 | 2.5P | 100 | 33 | 14 | 4 | 14 | 11 | ||

| M18×2.5 | 2.5P | 100 | 33 | 14 | 4 | 14 | 11 | ||

| M20×1.5 | 2.5P | 105 | 33 | 15 | 4 | 15 | 12 | ||

| M20×2.5 | 2.5P | 105 | 33 | 15 | 4 | 15 | 12 |

Why Choose Straight Flute Geometry?

The straight flute design is the most versatile geometry in the threading world. It offers maximum structural strength to the tap core, making it the ideal choice for creating threads in short-chipping materials.

Key Performance Features:

- Optimized Chip Control: Our advanced cutting-edge geometry breaks chips effectively, producing short, manageable chips even when machining long-chipping materials. This prevents bird-nesting and tool breakage.

- Lower Cost Per Component (CPC): Designed for high-speed machining, Minnexon taps significantly increase productivity. Faster cycle times and extended tool life directly result in a lower cost per threaded hole.

- Coolant-Through Options: For deep-hole applications or high-heat alloys, we offer Internal Through Coolant Taps. This feature ensures optimum transportation of swarf (chips) out of the hole and keeps the cutting edge cool.

The Minnexon Difference: Solid Carbide vs. HSS

Many suppliers offer standard High-Speed Steel (HSS) taps. While HSS is effective for general purposes, Minnexon focuses exclusively on Solid Carbide (Tungsten Steel).

Here is why upgrading to Solid Carbide transforms your production:

- Extreme Hardness & Wear Resistance: Tungsten Carbide is significantly harder than HSS. This allows our taps to maintain their cutting edge for much longer, even when machining abrasive materials like Cast Iron.

- Higher Cutting Speeds: Carbide taps can operate at cutting speeds 3x to 5x faster than HSS tools. This drastically reduces cycle time on your CNC machines.

- Superior Rigidity: Carbide minimizes tool deflection. This ensures that the thread pitch and tolerance remain precise, reducing the risk of oversized threads.

- Heat Resistance: Unlike HSS, which softens at high temperatures, Carbide maintains its hardness even under extreme heat, making it suitable for dry machining or high-speed operations.

Applications and Material Suitability

Our Metric Carbide Straight Flute Taps are the industry standard for machining materials that produce short chips. They are specifically optimized for:

1. Primary Application (Best Performance):

- Cast Irons: Grey Cast Iron (GG25, GG30), Nodular/Ductile Iron (GGG40-GGG70), Chilled Cast Iron.

- Hardened Steels: Heat-treated Steels, Tool Steels, and Die Steels. (Note: This is the specific domain where Carbide outperforms HSS by far.)

2. Non-Ferrous & Abrasive Materials:

- High-Silicon Aluminum: Cast Aluminum alloys with Si content >10% (Automotive engine blocks, etc.).

- Hard Copper Alloys: High-strength Bronze and Brass (Short-chipping).

3. Composite & Synthetic Materials:

- Reinforced Plastics: Glass Fiber Reinforced Plastics (GFRP), Carbon Fiber (CFRP).

- Engineering Plastics: PEEK, Bakelite (Thermosetting plastics).

Need to thread blind holes in other steels? Check out our range of Metric Carbide Spiral Flute Taps for superior chip evacuation. For high-speed through-hole applications, explore our Metric Carbide Spiral Point Taps.

Difficult-to-Machine Materials?

If you are working with hardened steel (HRC 45+) or require absolute thread safety without the risk of tap breakage, consider our Solid Carbide Thread Milling Cutters. Thread mills offer the highest process security for high-value components.

Get in Touch

We will provide you with feedback within 24 hours.