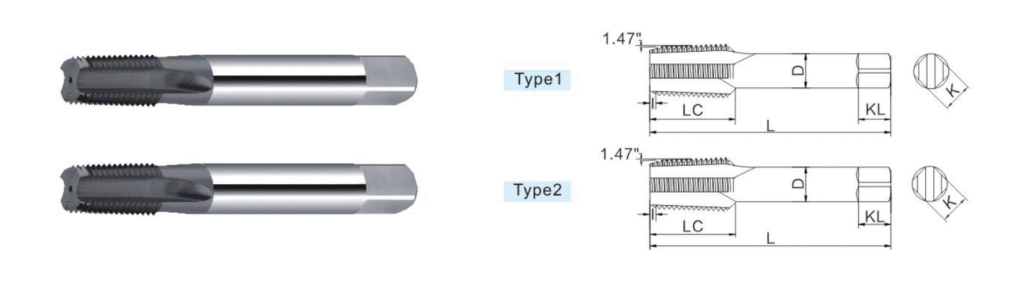

BSPT (RC/PT) Solid Carbide Straight Flute Pipe Tap

Precision Taper Threading for Tough & Abrasive Materials

Product Overview

Our BSPT solid carbide straight flute pipe taps (also known as RC/PT taper pipe taps) are engineered for high-precision internal pipe threading in abrasive or hard-to-machine materials. These taps conform to British Standard Pipe Taper (BSPT) specifications and are widely used in pressure-tight piping systems and fluid connections.

Crafted from ultra-fine grain solid tungsten carbide, these taps provide exceptional rigidity, wear resistance, and thermal stability, making them ideal for precision tapping of tapered threads in cast iron, alloy steels, aluminum, and non-ferrous metals. The straight flute design ensures effective chip control in short-chipping materials, especially in through-hole applications.

Key Features

Thread Type: BSPT (British Standard Pipe Taper), RC / PT

Solid Carbide Body: Provides long tool life and consistent performance in tough materials

Straight Flute Geometry: Optimized for through holes and short chip evacuation

Conical Thread Form: Perfectly suited for pressure-sealing pipe threads

Stable Tolerance Control: Maintains dimensional consistency in CNC and manual tapping

Applications

Internal pipe threading for hydraulic fittings, fluid connectors, compressed air systems, and pressure lines

Common in automotive, aerospace, machinery, oil & gas, and pneumatic components

Excellent performance in cast iron, copper alloys, mild steels, and aluminum extrusions

Designed for through holes, threaded bosses, and fittings requiring leak-tight connections

Advantages

Excellent wear resistance in abrasive materials

Accurate tapered thread profile for pressure-sealing joints

Stable chip evacuation in brittle or short-chip materials like cast iron

Designed for high-speed CNC tapping or manual threading applications

Reduces tool changes and downtime in mass production

Usage Recommendations

Ensure proper pre-hole taper size before tapping to achieve sealing performance

Use cutting fluid or MQL for smoother operation and longer tool life

Ideal for through-hole threading—for blind holes or long chips, use spiral taps

Avoid in materials that deform plastically without proper support (e.g., very soft metals)

Technical Specifications (Customizable)

| Thread | P | I | LC | L | D | Z | LK | K |

| PT1/16-28 | 0.907 | 2.5P | 16 | 60 | 6 | 4 | 7 | 4.9 |

| PT1/8-28 | 0.907 | 2.5P | 18 | 65 | 8 | 4 | 8 | 6 |

| PT1/4-19 | 1.337 | 2.5P | 19.5 | 70 | 11 | 4 | 11 | 9 |

| PT3/8-19 | 1.337 | 2.5P | 21 | 75 | 14 | 4 | 14 | 11 |

| PT1/2-14 | 1.814 | 2.5P | 28 | 80 | 18 | 4 | 17 | 14 |

Get in Touch

We will provide you with feedback within 24 hours.