BSPT (RC/PT) Spiral Flute Solid Carbide Pipe Tap

Precision Taper Threading for Blind Holes and Difficult Materials

Product Overview

The BSPT Spiral Flute Solid Carbide Pipe Tap (RC/PT thread) is a high-performance cutting tool engineered for creating accurate tapered pipe threads in blind holes and challenging-to-machine materials. Complying with British Standard Pipe Taper (BSPT) specifications, this tap is ideal for pressure-tight connections in fluid, pneumatic, and hydraulic systems.

Made from premium ultra-fine grain solid carbide, this tap delivers exceptional wear resistance, heat stability, and dimensional control. The spiral flute design provides superior chip evacuation, reducing cutting torque and minimizing breakage—especially in ductile or sticky materials such as stainless steel, aluminum alloys, and brass.

Key Features

Thread Standard: BSPT / RC / PT (55° taper thread)

Spiral Flute Geometry: Optimized for blind holes, improves chip removal and surface finish

Ultra-Hard Carbide Material: Exceptional rigidity, ideal for abrasive or tough materials

Leak-Tight Taper Threads: Perfect for applications requiring pressure sealing

CNC-Optimized: Designed for high-speed rigid tapping on modern machining centers

Applications

Precision tapping of blind holes for air-tight or fluid-tight joints

Used in hydraulic manifolds, pneumatic couplings, brass valves, and aluminum fittings

Suitable for stainless steel, tool steel, copper alloys, and die-cast aluminum

Applied across automotive, oil & gas, HVAC, machinery, and aerospace industries

Advantages

Smooth chip evacuation reduces jamming and tool breakage in blind holes

Precise, uniform tapered threads that ensure tight pressure seals

Works excellently on CNC, VMC, and automated tapping lines

Longer tool life compared to HSS or cobalt taps in abrasive environments

Delivers tight tolerances and better surface finishes even at high RPM

Usage Recommendations

Use tapping oil or MQL to enhance tool life and thread quality

Match pre-hole to BSPT pre-drill size chart for optimal sealing

Maintain correct tap depth and thread taper with controlled feed rates

Ideal for vertical CNC tapping in mass production environments

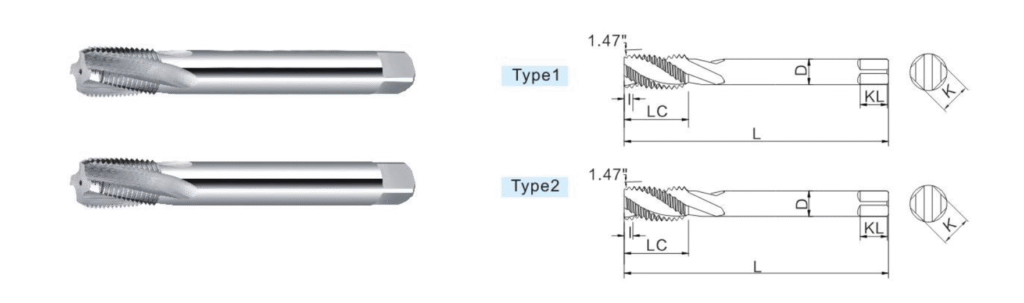

Technical Specifications (Customizable)

| Thread | P | I | LC | L | D | Z | ∠ | LK | K |

| PT1/16-28 | 0.907 | 2.5P | 16 | 60 | 6 | 3 | 15 | 7 | 4.9 |

| PT1/8-28 | 0.907 | 2.5P | 18 | 65 | 8 | 4 | 15 | 8 | 6 |

| PT1/4-19 | 1.337 | 2.5P | 19.5 | 70 | 11 | 4 | 15 | 11 | 9 |

| PT3/8-19 | 1.337 | 2.5P | 21 | 75 | 14 | 4 | 15 | 14 | 11 |

| PT1/2-14 | 1.814 | 2.5P | 28 | 80 | 18 | 4 | 15 | 17 | 14 |

Get in Touch

We will provide you with feedback within 24 hours.