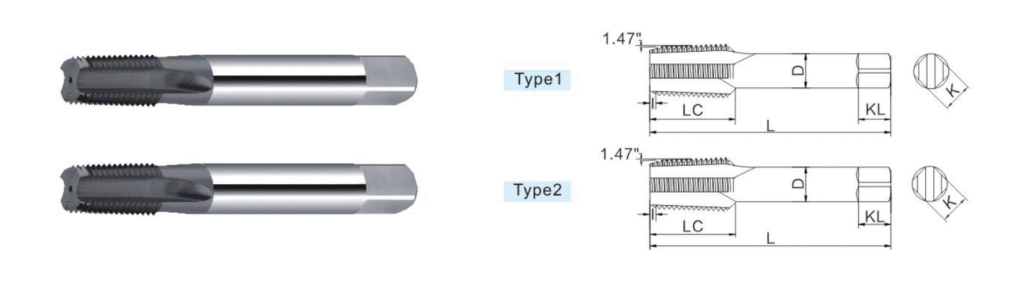

BSPP (PF/G) Solid Carbide Straight Flute Pipe Tap

Precision Threading for Parallel Pipe Connections

Product Overview

The BSPP solid carbide straight flute pipe tap—also referred to as the PF/G parallel pipe thread tap—is a high-precision tool designed for creating British Standard Pipe Parallel (G thread) internal threads. Ideal for applications that require mechanical fastening or thread sealing with a gasket or O-ring, this tap delivers outstanding performance in abrasive or hard-to-machine materials.

Manufactured from ultra-fine grain tungsten carbide, our BSPP tap offers exceptional rigidity, edge retention, and wear resistance. The straight flute geometry is optimized for through-hole tapping and short chip materials such as cast iron, brass, aluminum alloys, and mild steel. It is a trusted solution for high-volume CNC production, as well as precision applications in fluid, air, and mechanical systems.

Key Features

Thread Standard: BSPP / PF / G (British Standard Pipe Parallel, 55° Whitworth thread)

Material: Ultra-fine grain solid carbide (tungsten steel) for long tool life

Straight Flute Design: Ideal for through-hole tapping and consistent chip control

Precision Ground Threads: Delivers uniform pitch and tight dimensional tolerances

Excellent Surface Finish: Clean, burr-free threads ideal for leak-free sealing with washers or gaskets

Applications

Threading parallel pipe threads in hydraulic components, valves, manifolds, fittings, and housings

Ideal for aluminum die castings, brass fittings, ductile iron, and non-ferrous alloys

Commonly used in pneumatics, HVAC, water filtration, and low-pressure fluid systems

Suitable for CNC machining, automatic tapping machines, and high-precision manual setups

Advantages

Accurate thread geometry ensures tight fit and consistent torque

High-speed performance in CNC tapping with low risk of deflection or chipping

Exceptional tool life in mass production and abrasive materials

Optimized for through holes in short-chipping materials

Compatible with rigid tapping, synchronous spindles, and manual setups

Usage Recommendations

Always match the correct pre-drill diameter for BSPP threads

Use cutting oil or coolant to extend tool life and prevent chip welding

For best results, use on machining centers with tapping cycles

Avoid in blind holes or long-chip materials (consider spiral flute variants for those cases)

Technical Specifications (Customizable)

| Thread | P | I | LC | L | D | Z | LK | K |

| G1/16-28 | 0.907 | 2.5P | 16 | 65 | 6 | 4 | 7 | 4.5 |

| G1/8-28 | 0.907 | 2.5P | 18 | 65 | 8 | 4 | 8 | 6 |

| G1/4-19 | 1.337 | 2.5P | 24 | 70 | 11 | 4 | 11 | 9 |

| G3/8-19 | 1.337 | 2.5P | 25 | 75 | 14 | 4 | 14 | 11 |

| G1/2-14 | 1.814 | 2.5P | 28 | 85 | 18 | 4 | 17 | 14 |

Get in Touch

We will provide you with feedback within 24 hours.