BSPP (PF/G) Spiral Flute Solid Carbide Pipe Tap

High-Efficiency Threading for Parallel Pipe Connections

Product Overview

The BSPP Spiral Flute Solid Carbide Pipe Tap (also known as PF/G Parallel Pipe Tap) is a premium-grade threading tool designed to cut British Standard Pipe Parallel (G-thread) internal threads in blind or semi-blind holes. Featuring a spiral flute geometry, this tap ensures smooth chip evacuation and reduced cutting resistance, especially in ductile and sticky materials like aluminum, brass, and stainless steel.

Crafted from ultra-fine grain solid tungsten carbide, this tool delivers exceptional hardness, wear resistance, and thread accuracy, making it ideal for precision machining, automated tapping systems, and CNC applications where reliability and consistency are critical.

Key Features

Thread Standard: BSPP / PF / G (Parallel Pipe, 55° Whitworth profile)

Spiral Flute Design: Ideal for blind holes and improves chip clearance

Solid Carbide Construction: Maximum durability for high-volume and abrasive conditions

Clean, Accurate Threads: Ensures optimal sealing with gaskets or O-rings

Optimized for CNC & High-Speed Tapping: Suitable for modern machining environments

Applications

Creating parallel pipe threads in fluid connectors, pneumatic manifolds, low-pressure valves, and brass housings

Perfect for materials like aluminum alloys, non-ferrous metals, carbon steel, and stainless steel

Extensively used in HVAC, automotive fittings, water treatment components, and aerospace assemblies

Compatible with vertical and horizontal CNC tapping centers, as well as automated production lines

Advantages

Improved chip evacuation in blind holes prevents tool breakage and ensures clean threads

Leak-free parallel threads for connections using O-rings or flat seals

Superior tool longevity, even in abrasive or high-temperature conditions

High RPM compatible for automated tapping systems with rigid tapping capabilities

Consistent thread quality, ideal for precision or safety-critical assemblies

Usage Recommendations

Pre-drill using a BSPP-appropriate core hole diameter

Apply cutting fluid or MQL to enhance tool life and surface quality

Use in blind holes or soft materials where chip evacuation is crucial

For deep holes or continuous use, consider coated variants for heat protection

Technical Specifications (Customizable)

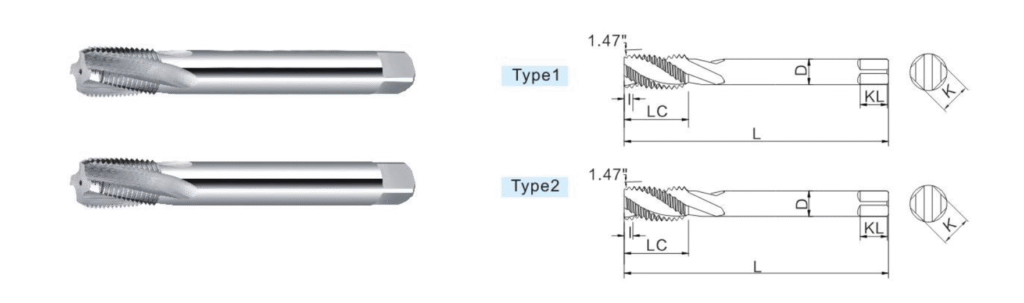

| Thread | P | I | LC | L | D | Z | ∠ | LK | K |

| G1/16-28 | 0.907 | 2.5P | 16 | 65 | 6 | 3 | 15 | 7 | 4.5 |

| G1/8-28 | 0.907 | 2.5P | 18 | 65 | 8 | 3 | 15 | 8 | 6 |

| G1/4-19 | 1.337 | 2.5P | 24 | 70 | 11 | 4 | 15 | 11 | 9 |

| G3/8-19 | 1.337 | 2.5P | 25 | 75 | 14 | 4 | 15 | 14 | 11 |

| G1/2-14 | 1.814 | 2.5P | 28 | 85 | 18 | 4 | 15 | 17 | 14 |

Get in Touch

We will provide you with feedback within 24 hours.