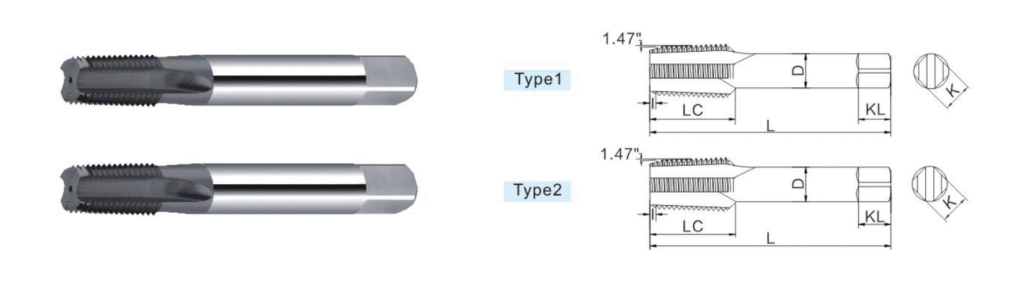

NPT Solid Carbide Straight Flute Pipe Tap

Precision Taper Threading for High-Pressure Pipe Systems

Product Overview

The NPT Solid Carbide Straight Flute Pipe Tap is engineered for cutting National Pipe Taper (NPT) threads into a wide range of materials, ensuring secure and pressure-tight connections in fluid, gas, and hydraulic systems. Featuring a straight flute geometry and constructed from ultra-fine grain solid tungsten carbide, this tap is ideal for through-hole threading in rigid, abrasive, or high-volume applications.

Whether you’re machining carbon steel, stainless steel, cast iron, or non-ferrous alloys, this tool delivers consistent thread quality, tight tolerances, and long tool life—perfect for both manual and CNC production environments where durability and accuracy are non-negotiable.

Key Features

Thread Type: NPT (National Pipe Taper), 60° thread angle

Material: Ultra-hard solid tungsten carbide for extended tool life

Flute Design: Straight flutes optimized for through-hole applications

Leak-Proof Threading: Creates taper threads for pressure-tight joints

Precision Ground: High thread profile accuracy and smooth finishes

Applications

Machining taper pipe threads for fluid or air-tight systems in pneumatic, hydraulic, gas, and water applications

Used in pipe fittings, valves, manifolds, machinery housings, and industrial piping systems

Suitable for carbon steel, tool steel, cast iron, brass, aluminum, and other alloys

Compatible with CNC tapping, automatic threading machines, and manual setups for prototyping or small batches

Advantages

High thread consistency for air-tight and fluid-tight connections

Rigid and durable for aggressive materials or high-speed tapping

Ideal for through-hole operations with minimal chip congestion

Superior wear resistance compared to HSS or cobalt taps

Compatible with rigid tapping systems, high-speed spindles, and manual tapping fixtures

Usage Recommendations

Match with the correct NPT pre-drilled hole diameter for best sealing results

Use cutting oil or coolant to reduce heat and extend tool life

Avoid in blind hole applications—use spiral flute versions for those cases

Regularly inspect for wear to maintain thread quality and avoid galling

Technical Specifications (Customizable)

| Thread | P | I | LC | L | D | Z | LK | K |

| NPT1/16-27 | 0.941 | 2.5P | 16 | 60 | 6 | 4 | 7 | 4.5 |

| NPT1/8-27 | 0.941 | 2.5P | 18 | 65 | 8 | 4 | 8 | 6 |

| NPT1/4-18 | 1.411 | 2.5P | 19.5 | 70 | 11 | 4 | 11 | 9 |

| NPT3/8-18 | 1.411 | 2.5P | 21 | 75 | 14 | 4 | 14 | 11 |

| NPT1/2-14 | 1.814 | 2.5P | 27 | 80 | 18 | 4 | 17 | 14 |

Get in Touch

We will provide you with feedback within 24 hours.