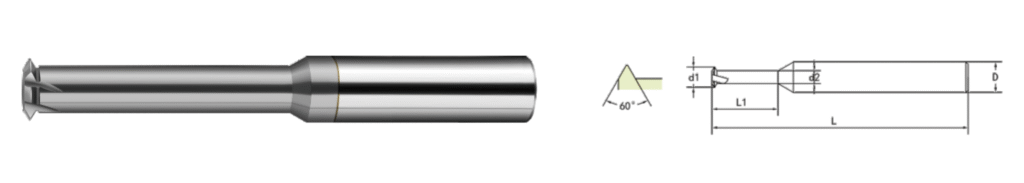

UN Single-Form Thread Mill | Solid Carbide Thread Milling Cutter

- Selected solid carbide tungsten steel material, manufactured using German Walter equipment.

- Multiple coating options available, including uncoated, AlTiN, TiAlN, and DLC coatings.

- Suitable for machining 60° UN threads, compatible with various thread pitches threads.

- Applicable for both left-hand and right-hand threads, as well as internal and external threads.

Product Overview

Our Solid Carbide UN Single-Point Thread Mill is designed for high-accuracy threading operations across a wide range of materials and applications. Manufactured from ultra-fine grain tungsten carbide, this tool enables precise and versatile machining of Unified National (UN) threads, supporting both internal and external, as well as right-hand and left-hand threads.

With its single-tooth geometry, this thread mill delivers exceptional control over thread pitch and depth, making it ideal for CNC helical interpolation. It is especially suited for industries that demand thread consistency in aerospace, automotive, medical, and mold manufacturing.

To further improve performance and longevity, a range of specialized coatings is available depending on the workpiece material—boosting tool life and machining efficiency.

Key Features

Thread Standard: UN (Unified National, UNC/UNF/UNEF)

Geometry: Single-point tooth for ultra-precise thread form

Thread Types: Internal & external / right-hand & left-hand threads

Material: Solid tungsten carbide for superior hardness and wear resistance

Coating Options: Tailored coatings for different materials (TiAlN, AlCrN, DLC, etc.)

Material Compatibility & Coating Recommendations

| Material Type | Recommended Coating |

|---|---|

| 45# Medium Carbon Steel | TiAlN or AlCrN |

| Stainless Steel (304/316) | AlCrN or TiSiN |

| P20 Tool Steel | TiAlN |

| Cast Iron | TiCN or uncoated |

| Titanium Alloys | TiSiN or DLC |

| High-Temperature Alloys (Inconel, Hastelloy) | AlCrN or nano-composite coatings |

Choosing the correct coating significantly enhances heat resistance, reduces wear, and improves cutting efficiency, especially when threading difficult materials or at high spindle speeds.

Advantages

Universal Threading: One tool handles all thread directions and locations

Exceptional Precision: Single-tooth control for tight tolerance threads

Optimized Coatings: Match the tool to the material for maximum performance

Wide Material Range: From mild steel to titanium and heat-resistant alloys

Minimal Vibration: Improved stability during deep or fine thread cutting

Cost Efficiency: Reduced tool inventory with multipurpose capability

Usage Recommendation

Use helical interpolation (G02/G03) for accurate thread milling paths

Choose appropriate RPM/feed based on coating, material, and thread pitch

Apply high-pressure coolant or MQL for stainless/titanium alloys

Ensure tool overrun clearance in blind hole applications

For high-volume production, consider a dedicated tool path simulation to avoid tool overload

Technical Specifications (Customizable)

| UNC | UNF | tpi | d1/mm | L1/mm | D/mm | L/mm | F |

|---|---|---|---|---|---|---|---|

| UNC4-40 | - | 40 | 2.13 | 8.2 | 4 | 50 | 3 |

| UNC6-32 | - | 32 | 2.56 | 7.4 | 4 | 50 | 3 |

| UNC10-32 | - | 32 | 3.8 | 10 | 4 | 50 | 3 |

| UNC8-32 | - | 32 | 3.2 | 11 | 4 | 50 | 3 |

| - | UNF1/4-28 | 28 | 5 | 16 | 6 | 50 | 4 |

| UNC1/4-20 | - | 20 | 4.8 | 16 | 6 | 50 | 4 |

| UNC5/16-18 | - | 18 | 6 | 16 | 6 | 50 | 4 |

| UNC3/8-16 | - | 16 | 7.7 | 20 | 8 | 60 | 4 |

| - | UNF3/8-24 | 24 | 8 | 25 | 8 | 60 | 4 |

| UNC1/2-13 | - | 13 | 10 | 30 | 10 | 75 | 5 |

| - | UNF9/16-18 | 18 | 12 | 35 | 12 | 75 | 5 |

| - | UNF3/4-16 | 16 | 12 | 35 | 12 | 75 | 5 |

Get in Touch

We will provide you with feedback within 24 hours.