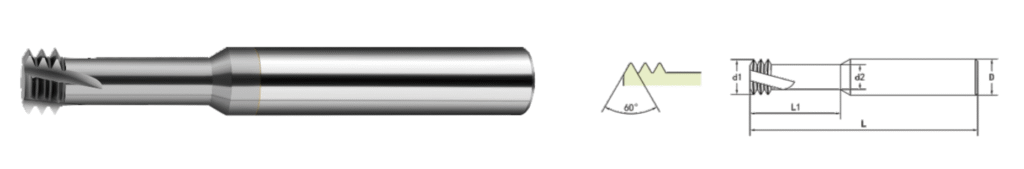

UN Tri-Form Thread Mill | Solid Carbide Thread Milling Cutter

- Selected solid carbide tungsten steel material, manufactured using German Walter equipment.

- Multiple coating options available, including uncoated, AlTiN, TiAlN, and DLC coatings.

- Suitable for machining 60° UN threads.

- Ultra-strong cutting edge design reduces the risk of breakage inside holes, provides chipping resistance, and ensures long tool life.

Applicable for both left-hand and right-hand threads, as well as internal and external threads.

Product Overview

The Solid Carbide UN Triple-Tooth Thread Mill is engineered for high-speed, high-efficiency thread milling in Unified Thread Standard (UN) formats. Built from premium-grade tungsten carbide, this tool features a three-flute cutting geometry that balances strength, chip evacuation, and cycle speed—making it an ideal choice for medium to large batch production of internal and external threads.

Designed for use in CNC machining centers, this thread mill can cut left-hand and right-hand threads with ease. It supports threading in a wide variety of materials—from aluminum and copper to stainless steel, tool steel, cast iron, titanium alloys, and even nickel-based superalloys—with a range of custom coatings available to match each application.

Key Features

UN Thread Standard: Compatible with UNC, UNF, UNEF sizes

Triple-Tooth Geometry: Offers a balance of speed, tool life, and stability

Thread Versatility: Cuts both internal/external and left/right-hand threads

Tungsten Carbide Core: Maintains dimensional accuracy even in tough materials

Custom Coatings: Optimized surface treatments based on workpiece material

Material Compatibility & Coating Recommendations

| Workpiece Material | Recommended Coating Type |

|---|---|

| Aluminum / Copper | DLC or uncoated |

| 45# Carbon Steel | TiAlN or TiCN |

| Stainless Steel (304/316) | AlCrN or TiSiN |

| P20 Mold Steel | TiAlN or nano-coating |

| Cast Iron | TiCN or TiN |

| Titanium Alloys | TiSiN or DLC |

| High-Temp Alloys (Inconel, Hastelloy) | AlCrN or advanced nano coatings |

Choosing the correct coating based on the material significantly improves cutting performance, chip evacuation, and tool longevity.

Advantages

Faster Machining: Triple-tooth design allows higher feed rates

Clean Thread Profile: Produces precise, burr-free UN threads

Multi-Directional: Handles both RH and LH thread forms in one tool

Universal Material Use: Switch between aluminum, stainless, or alloy steel with the correct coating

Extended Tool Life: High hardness carbide with material-matched coatings resists wear

Reduced Downtime: Fewer tool changes needed thanks to wide material compatibility

Usage Recommendation

Program using G02/G03 helical interpolation for optimal thread paths

Reduce spindle speed slightly when threading heat-resistant alloys

For blind holes, check thread mill clearance behind the cutting edge

Use high-pressure coolant for chip evacuation in deep threads

Select tool length and pitch based on thread depth and standard

Technical Specifications (Customizable)

| UNS | UNC | UNF | tpi | d1/mm | L1/mm | D/mm | L/mm | F |

|---|---|---|---|---|---|---|---|---|

| UNC1-64 | UNF2-64 | 64 | 1.4 | 4 | 4 | 50 | 3 | |

| UNF1-72 | 72 | 1.44 | 3.8 | 4 | 50 | 3 | ||

| UNF0-80 | 80 | 1.18 | 3.5 | 4 | 50 | 3 | ||

| UNC3-48 | UNF4-48 | 48 | 1.9 | 5 | 4 | 50 | 3 | |

| UNC8-36 | 36 | 3.31 | 11 | 4 | 50 | 3 | ||

| UNC10-24 | 24 | 3.58 | 11 | 4 | 50 | 3 | ||

| UNF10-32 | 32 | 3.8 | 12 | 4 | 50 | 3 | ||

| UNC2-56 | UNF3-56 | 56 | 1.65 | 5 | 4 | 50 | 3 | |

| UNC6-32 | 32 | 2.56 | 7.5 | 4 | 50 | 3 | ||

| UNC4-40 | 40 | 2.13 | 6 | 4 | 50 | 3 | ||

| UNC4-40 | 40 | 2.13 | 8.2 | 4 | 50 | 3 | ||

| UNC8-32 | 32 | 3.2 | 11 | 4 | 50 | 3 | ||

| UNC5-40 | UNF6-40 | 40 | 2.46 | 8 | 4 | 50 | 3 | |

| UNF1/4-28 | 28 | 5 | 15 | 6 | 50 | 3 | ||

| UNC5/16-24 | 24 | 5.95 | 18 | 6 | 60 | 3 | ||

| UNC1/4-20 | 20 | 4.87 | 14 | 6 | 50 | 3 | ||

| UNS1/4-36 | 36 | 5 | 12 | 6 | 50 | 3 | ||

| UNC5/16-18 | 18 | 5.9 | 18 | 6 | 50 | 3 | ||

| UNC3/8-16 | 16 | 7.65 | 20 | 8 | 60 | 3 | ||

| UNC5/16-24 | 24 | 6.88 | 21 | 8 | 60 | 3 | ||

| UNF3/8-24 | 24 | 7.4 | 20 | 8 | 60 | 4 | ||

| UNC1/2-13 | 13 | 9.9 | 25 | 10 | 75 | 4 | ||

| UNF7/16-20 | 20 | 9.5 | 28 | 10 | 75 | 4 | ||

| UNC7/16-14 | 14 | 9 | 28 | 10 | 75 | 4 | ||

| UNF9/16-18 | 18 | 11.9 | 30 | 12 | 75 | 4 | ||

| UNF9/16-24 | 24 | 11.9 | 29 | 12 | 75 | 4 |

Get in Touch

We will provide you with feedback within 24 hours.