- 2025-08-01

- 0 Comment

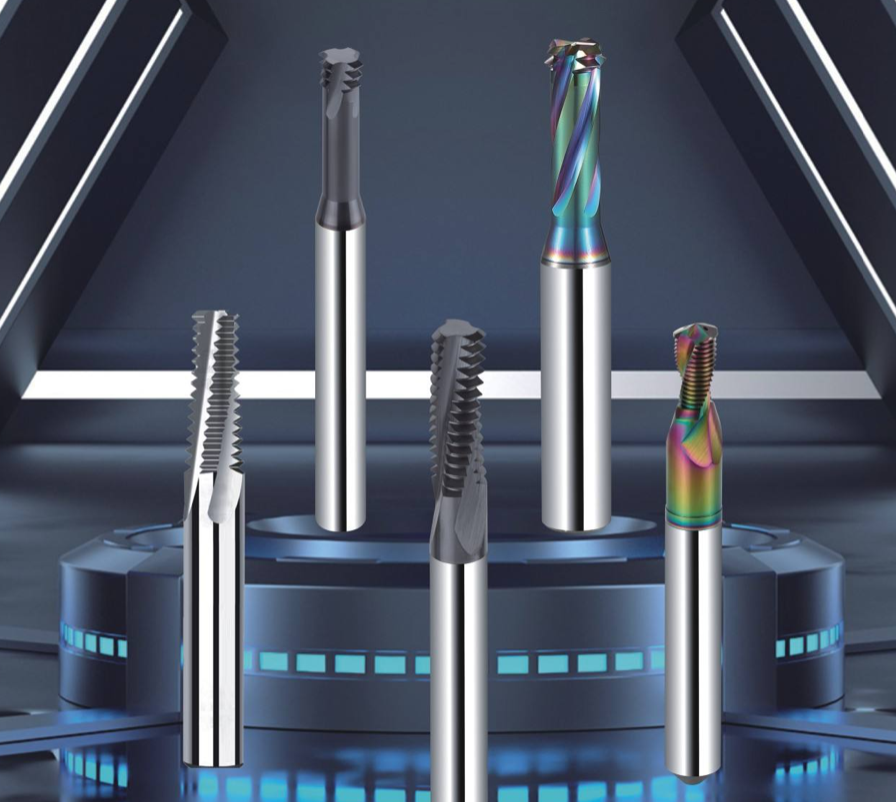

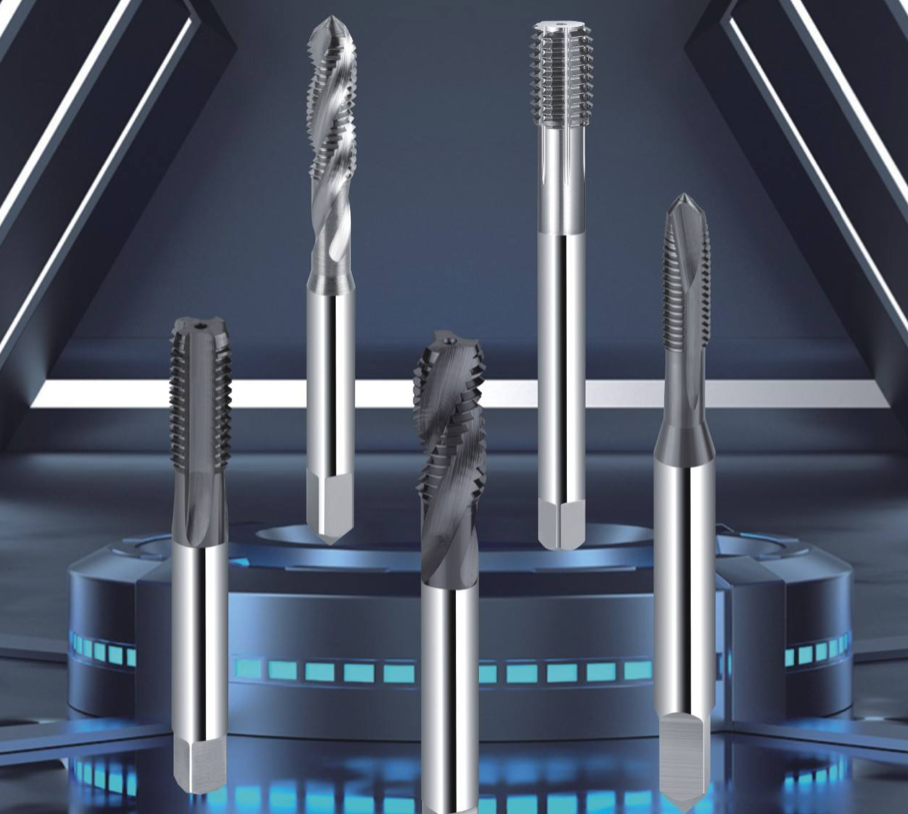

Tungsten Carbide Thread Mills vs Tungsten Carbide Taps: Key Differences and Applications

When it comes to precision threading in metalworking, two tools dominate the workshop: tungsten carbide thread mills and tungsten carbide taps (including solid carbide taps and CNC spiral taps). Both are made from high-strength tungsten carbide (hard alloy), but each serves unique purposes. Choosing the right tool can drastically improve threading efficiency, surface finish, and tool life.

1. Tool Design Differences

| Feature | Tungsten Carbide Thread Mill | Tungsten Carbide Tap |

|---|---|---|

| Cutting Method | Helical interpolation; multi-pass cutting | Single-pass threading along axis; includes CNC spiral taps |

| Thread Type | Internal & external; right-hand & left-hand | Usually internal threads; limited left-hand options |

| Teeth Design | Single, triple, or full-profile teeth | Single or multiple flutes (straight or spiral), solid carbide taps available |

| Precision & Surface Finish | ±0.001 mm; superior thread surface | Good accuracy, but minor deviations may occur |

| CNC Compatibility | Fully compatible with helical cycles | Can be manual or CNC; CNC spiral taps ideal for complex threading |

| Reusability & Tool Life | Long tool life with proper coating | Shorter life in hard materials; easy to break if misused |

2. Material Compatibility

Thread mills and solid carbide taps excel in machining a wide range of materials, including:

Aluminum, copper, and soft metals

45# steel, stainless steel, P20, and cast iron

Titanium alloys and high-temperature superalloys

CNC spiral taps are particularly effective for blind holes or difficult chip evacuation, where standard taps may fail.

3. Advantages of Tungsten Carbide Thread Mills

High precision and repeatability – Ideal for aerospace, automotive, and industrial components.

Versatility – One tool can cut both internal and external threads of multiple diameters.

Custom coatings – TiAlN, TiCN, AlCrN, and DLC coatings improve performance across different materials.

Longer tool life – Can withstand high-speed machining and challenging materials.

Reduced cycle time – Multi-tooth or full-profile designs allow faster threading than traditional taps.

4. Advantages of Tungsten Carbide Taps and CNC Spiral Taps

Easy internal thread creation for manual and CNC operations

CNC spiral taps provide smoother chip evacuation in blind holes

Solid carbide taps offer higher hardness and wear resistance for tough materials

Cost-effective for small batch or soft material applications

5. Choosing the Right Tool

| Scenario | Recommended Tool |

|---|---|

| High-precision CNC threading | Thread mill |

| Threading hard or exotic alloys | Thread mill with PVD coating |

| Small batches or soft metals | Solid carbide tap or spiral tap |

| Blind holes with difficult chip evacuation | CNC spiral tap |

6. Conclusion

While tungsten carbide thread mills excel in flexibility, precision, and tool life, solid carbide taps and CNC spiral taps are perfect for simpler or blind-hole threading. Understanding the differences, material compatibility, and cutting methods ensures better machining efficiency, surface finish, and tool durability.

Call to Action

Explore our premium range of tungsten carbide thread mills, solid carbide taps, and CNC spiral taps. With precision up to ±0.001 mm and a wide selection of coatings for any material, our tools are designed to maximize threading efficiency and tool life.

📩 Contact us today for custom sizes, coating recommendations, or a quotation for your project.