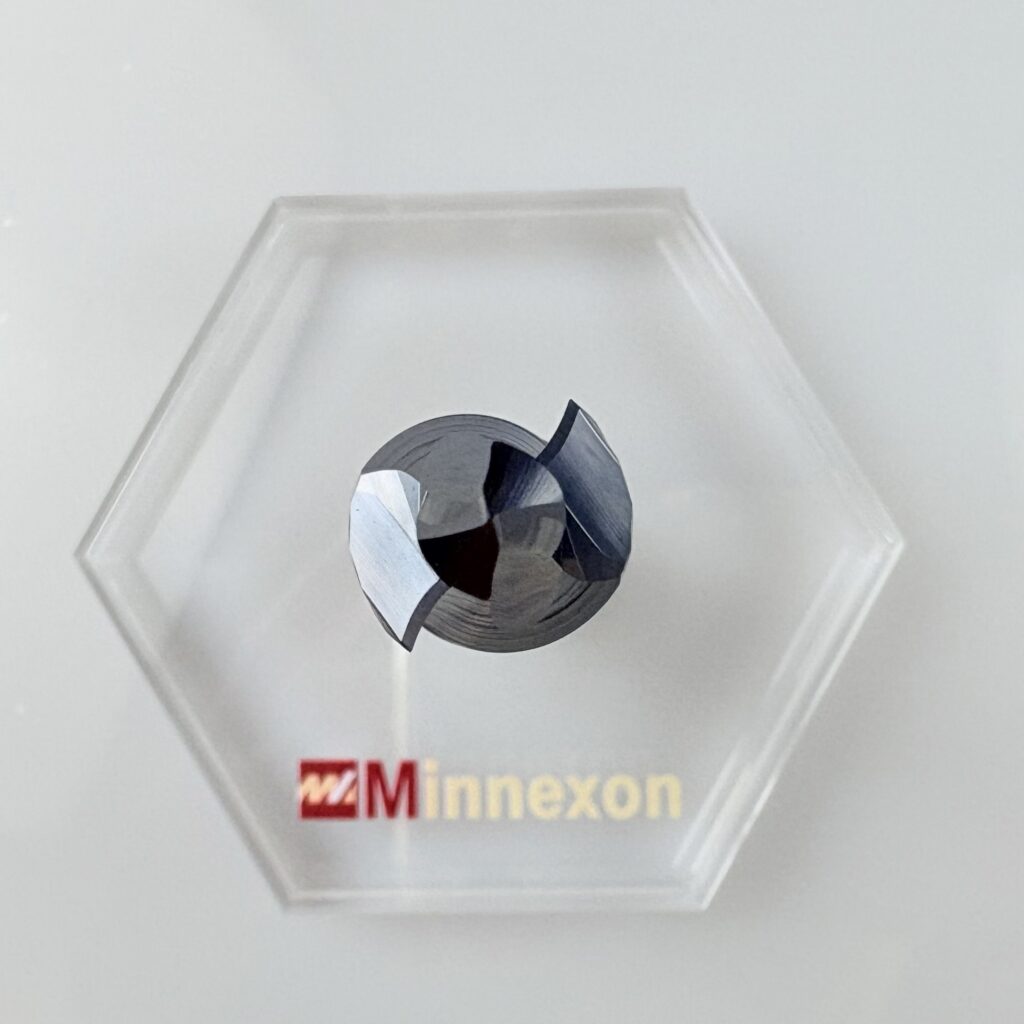

Solid Carbide Step Drill Bit | Precision Stepped Drill for Metal

Step Diameters: Multiple diameters per design (2-step / 3-step / multi-step)

Step Lengths: Customized according to hole depth requirements

Shank Diameter (d): 3 mm – 20 mm

Overall Length (L): 30 mm – 150 mm

Coating: TiAlN / AlTiN / DLC / Uncoated

Minnexon is a professional manufacturer of solid carbide cutting tools. Our solid carbide step drill bits, also known as stepped drills or cone drill bits, are designed for accurate and efficient hole making in metal, stainless steel, copper, and brass.

These precision tools combine multiple hole diameters into one drill, saving time, improving accuracy, and reducing tool changes.

Solid Carbide Step Drill Bit Overview

A step drill bit has multiple cutting diameters, or “steps,” along its body. Each step can drill a different hole size in one operation. The solid carbide construction provides excellent hardness, wear resistance, and stability during high-speed cutting.

Step drill bits are ideal for machining thin to moderately thick materials, offering clean holes and smooth finishes with minimal burrs.

Features

High-Precision Carbide Body: Excellent hardness and long service life.

Multi-Step Design: Drill multiple hole sizes without tool change.

Smooth Hole Finish: Produces clean edges and minimal burrs.

High Efficiency: Reduces cycle time and increases production speed.

Stable Performance: Maintains accuracy under high cutting loads.

Applications of Stepped Drill Bit | Cone Drill Bit

Minnexon solid carbide step drill bits are suitable for:

Copper and Brass Machining: Perfect for high-speed drilling with clean surface finish.

Sheet Metal Fabrication: Ideal for electrical panels, enclosures, and brackets.

Stainless Steel Components: Durable enough for demanding industrial applications.

Precision Manufacturing: Suitable for automated lines and CNC machines.

Advantages of Minnexon Solid Carbide Step Drill

One Tool for Multiple Hole Sizes: Simplifies tool management and increases efficiency.

High Durability: Carbide construction withstands heavy loads and long production runs.

Superior Hole Quality: Produces smooth, accurate holes with minimal post-processing.

Cost Savings: Fewer tool changes and longer tool life reduce overall production cost.

Versatile Applications: Works for copper, brass, steel, and stainless steel components.

Customized Step Drill Bits for Special Requirements

At Minnexon, we understand that every manufacturer has unique production needs. We provide customized solid carbide step drill bits designed to your specifications, including:

Custom step diameters and lengths

Special coating options (TiAlN, AlTiN, DLC)

Specific flute geometry for chip evacuation

Custom shank designs for CNC or manual machines

Our engineering team works closely with customers to ensure that each step drill meets exact tolerance and performance requirements.

Why Choose Minnexon

With years of experience in carbide tool manufacturing, Minnexon is trusted by global industries for its precision, quality, and innovation.

All Minnexon solid carbide step drill bits are produced under strict quality control and advanced grinding technology.

We serve customers in automotive, aerospace, electrical, and precision machining industries, helping them achieve better efficiency and performance.

Get in Touch

We will provide you with feedback within 24 hours.