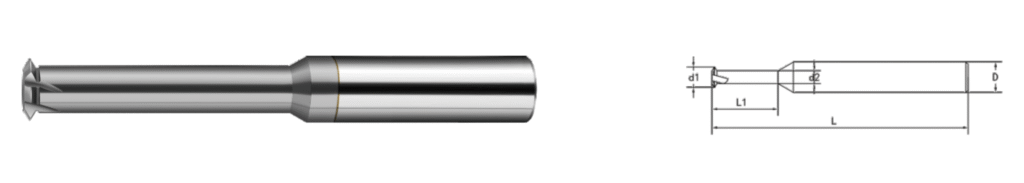

ACME Single-Form Thread Mill | 29 Degree Solid Carbide Thread Milling Cutter

- Selected solid carbide tungsten steel material, manufactured using German Walter equipment.

- Multiple coating options available, including uncoated, AlTiN, TiAlN, and DLC coatings.

- Suitable for machining 29° ACME threads.

- Applicable for both left-hand and right-hand threads, as well as internal and external threads.

ACME 29° Single-Form Thread Mill for Trapezoidal Threads

The ACME Single Form Thread Milling Cutter is designed for precision and flexibility in thread machining. It uses a single cutting form that allows accurate and consistent thread profiles. This tool is ideal for ACME threads, trapezoidal threads, and other custom thread forms. It helps you produce clean and smooth threads with high repeatability.

Key Features

High Precision:

The single form design ensures that each pass cuts only a small part of the thread. This reduces cutting force and improves accuracy. It also makes the surface finish cleaner.

Long Tool Life:

Because the cutter removes less material at a time, tool wear is lower. You can run longer machining cycles with stable performance.

Versatile Use:

You can use the ACME single form cutter on many materials such as steel, stainless steel, aluminum, and titanium. It fits most CNC machines and works with different pitches and diameters.

Easy Programming:

You can create threads by simple helical interpolation on your CNC machine. One cutter can make different thread sizes, which reduces tool change time and cost.

Reliable Thread Quality:

The tool produces precise and uniform threads. It helps avoid problems such as burrs, chatter, and poor fit.

Technical Specifications (Customizable)

| Thread Size | TPI | Pitch | Angle | d1/mm | L1/mm | D/mm | L/mm | Flutes |

|---|---|---|---|---|---|---|---|---|

| ACME1/4-16 | 16 | 1.587 | 29° | 4.7 | 15 | 6 | 57 | 4 |

| ACME5/16-14 | 14 | 1.814 | 29° | 6 | 20 | 6 | 57 | 4 |

| ACME3/8-12 | 12 | 2.116 | 29° | 7.2 | 25 | 8 | 65 | 4 |

| ACME7/16-12 | 12 | 2.116 | 29° | 7.2 | 25 | 8 | 65 | 4 |

| ACME1/2-10 | 10 | 2.54 | 29° | 10 | 35 | 10 | 75 | 4 |

| ACME5/8-8 | 8 | 3.175 | 29° | 12 | 35 | 12 | 75 | 4 |

| ACME3/4-6 | 6 | 4.233 | 29° | 12 | 35 | 12 | 75 | 4 |

| ACME7/8-6 | 6 | 4.233 | 29° | 12 | 35 | 12 | 75 | 4 |

FAQs about ACME Single Form Thread Milling Cutters

1. What is a single form thread milling cutter?

A single form thread milling cutter has one thread profile on the tool. It machines the thread shape by making several passes around the hole using a CNC program.

2. What are the advantages over traditional taps?

It does not need a dedicated tap for each thread size. One tool can make different sizes by changing the CNC path. It also avoids tap breakage and gives better control over thread depth and pitch.

3. Can it cut internal and external threads?

Yes. You can use it for both internal and external threads by adjusting the tool path.

4. What materials can it cut?

It works well with most metals, including steel, stainless steel, aluminum, brass, and titanium.

5. What machine is needed?

It requires a CNC milling machine that supports helical interpolation.

Get in Touch

We will provide you with feedback within 24 hours.