- 2025-11-20

- 0 Comment

Mastering Stainless Steel Threads: Precision Thread Milling Solutions

Threading stainless steel has always been a challenge in machining. Materials like 304 and 316L are tough, prone to work hardening, and difficult to clear chips. Tapping with a conventional tap often results in broken tools, burrs, and inconsistent accuracy, especially in deep holes or thin-walled parts. Thread milling cutters provide a reliable and efficient solution.

Common Machining Problems

- Frequent tap breakage: high cutting forces and torque spikes

- Burrs in deep holes: poor chip evacuation and work hardening

- Thin-walled part deformation: excessive cutting forces and vibration

How Thread Milling Solves These Issues

- Reduces cutting forces: spiral or circular interpolation engages fewer teeth at a time

- Improves chip evacuation: single- or few-flute cutters produce short, uniform chips

- Enhances precision: CNC control allows diameter adjustments within ±0.01 mm

- Flexible for multiple sizes: one cutter can handle different diameters and pitches

- Smooth surface finish: Ra ≤ 1.6 μm, suitable for medical, food, and aerospace parts

Cutter Selection

- Coating: TiAlN for all stainless steel applications

- Tooth type:

- Shallow/standard holes → full-thread cutter for efficiency

- Deep/thin-walled holes → single-flute cutter for lower load and smooth chip evacuation

Machining Parameters and Key Considerations

Feed rate is the most common error source in thread milling, especially with full-thread cutters. Too high feed can break the cutter.

Example Parameters (M10 × 1.5, 8 mm shank Multi-form cutter)

| Parameter | Recommended Range | Notes |

|---|---|---|

| Spindle speed | 3000–3200 rpm | Stable CNC operation |

| Feed per tooth | 180–200 mm/min | Full-thread cutter feed should not exceed 200 |

| Depth per pass | 0.5–1 mm | 3–4 layers, left-right pass layering |

| Coolant | High-pressure water or mist | Extend tool life, reduce work hardening |

| Cutting method | Bottom-up spiral interpolation, left-right layers | Reduce vibration and burrs |

⚠ After confirming stable machining, feed and speed can be further optimized to improve efficiency while ensuring safe cutting forces.

Real Broken Tool Case (UNF1-12, 16 mm shank)

A customer used 3500 rpm and 250 mm/min feed to machine a UNF1-12 thread with a 16 mm shank thread milling cutter, resulting in tool breakage.

Analysis showed the feed was too high, causing a sudden spike in cutting force.

By reducing the feed to 180 mm/min, using bottom-up milling, 3–4 layers, left-right layering, the cutter successfully machined the threads with stable precision and normal tool life.

Application Cases

Case A: 316L Valve Deep Hole M10 × 1.5

- Problem: tap breakage and heavy burrs

- Solution: TiAlN single-flute thread milling cutter

- Result: ±0.01 mm precision, Ra < 1.6 μm, tool life tripled

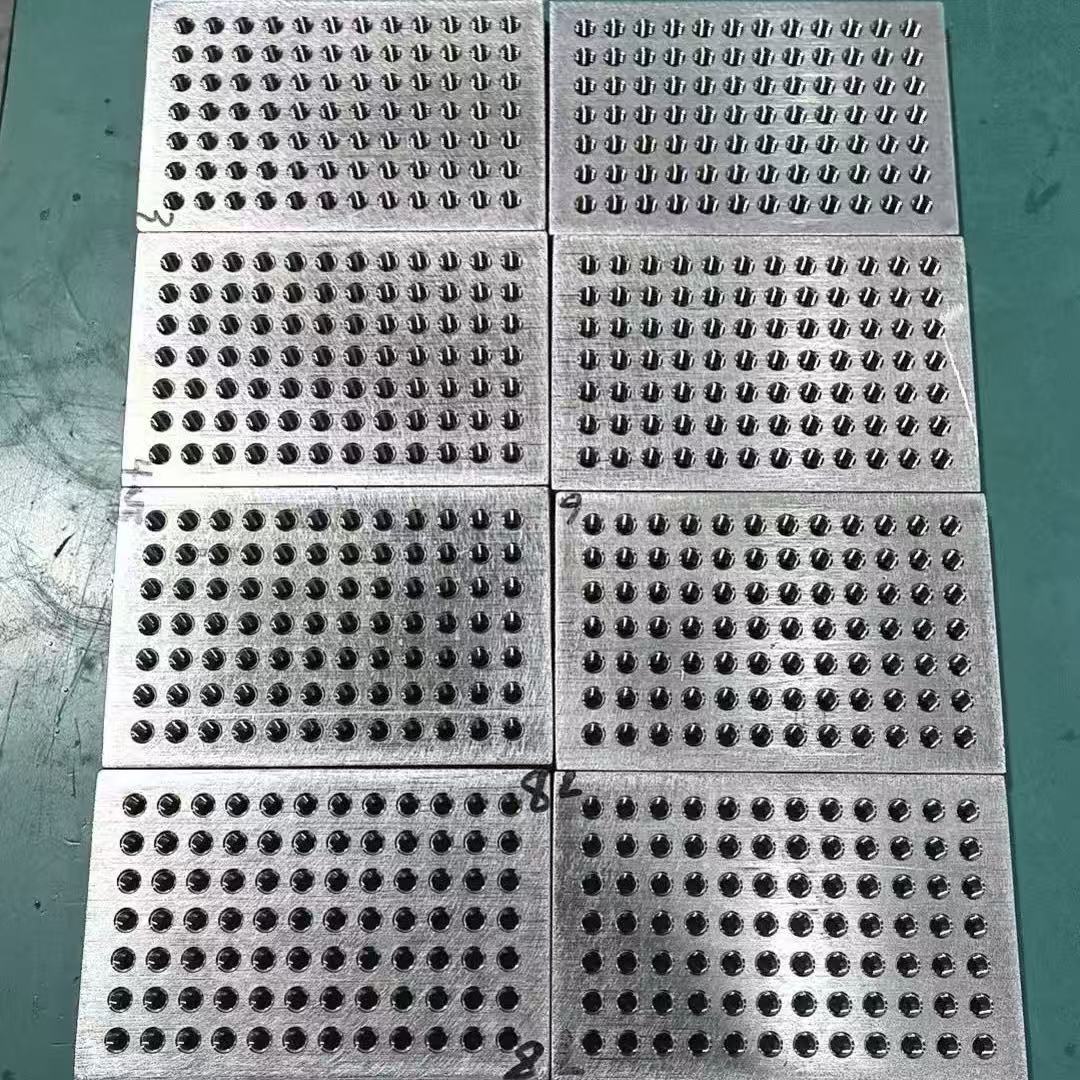

Case B: 304 Thin-Walled Plate Test

- Description: in-house lab tests on stainless steel plates

- Result: smooth threading, high precision, minimal burrs, tool condition excellent

- Notes: single-flute cutter + spiral down milling + TiAlN coating + 180 mm/min feed

Frequently Asked Questions

Q1: What happens if the feed is too high for a full-thread cutter?

A: Cutting force spikes can break or chip the cutter. Keep feed ≤ 200 mm/min and use layered passes.

Q2: Should deep holes always use a single-flute cutter?

A: Single-flute is safer for chip evacuation, but multi-flute is possible with a rigid machine.

Q3: Is thread milling slower than tapping?

A: Single-thread milling may be slightly slower per piece, but for deep holes, thin walls, or high precision, milling is more efficient overall and reduces scrap.

Q4: How to reduce burrs?

A: Use climb milling, proper feed, sufficient cooling, and TiAlN-coated cutters.

Explore more of our thread end mills

-

ACME Single-Form Thread Mill | 29 Degree Solid Carbide Thread Milling Cutter

Read more -

BSPP(G) Multi-Form 55 degree Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

UN Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

Metric Tri-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more