Single-Form Thread Mills for Titanium and Heat-Resistant Alloys

Conquer sticky materials with Minnexon single-form thread mills for titanium. Featuring an exclusive Golden Coating for superior heat resistance. Perfect for Aerospace & Medical machining.

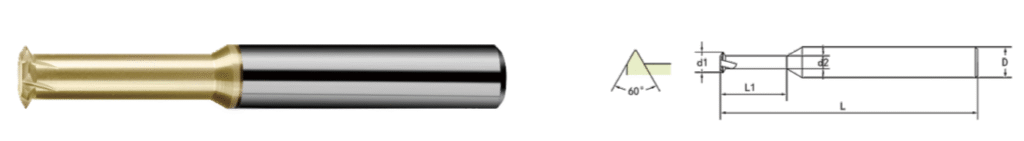

- Universal 60° Geometry: You can use this tool for any 60-degree thread angle.

- Metric and UN Compatible: One cutter works for both Metric ISO threads and American UN threads.

- Internal and External: Safely machine both internal and external threads.

- Left and Right Hand: You can create right-hand or left-hand threads simply by changing the CNC program.

Are You Struggling with Machining Titanium Threads?

Machining hard and sticky materials is a challenge. If you work in the aerospace or medical industries, you likely face these common issues:

- Material Adhesion: Sticky materials like Titanium and Kovar cause built-up edges on the tool.

- Short Tool Life: High heat generation leads to rapid wear when machining Inconel 718 or other nickel-based alloys.

- Poor Surface Finish: Vibration and deflection ruin the thread quality.

- Broken Taps: A broken tap in an expensive part is a costly mistake.

You need a reliable solution. Minnexon introduces our specialized solid carbide single-form thread mills. We designed these tools specifically to solve problems with difficult-to-cut materials.

The Minnexon Solution: Exclusive Golden Coating

We do not just sell tools. We provide process security.

1. Strategic “Golden Coating” Partnership

This is our core advantage. Minnexon has formed a strategic partnership with a world-leading coating company. Together, we developed a specialized Golden Coating. It is engineered specifically for thread milling titanium alloys.

- Superior Lubricity: The coating significantly reduces friction. This prevents the material from sticking to the cutting edge. It ensures smooth chip evacuation.

- Extreme Heat Resistance: The coating maintains high hardness even at high temperatures. It acts as a heat shield. This effectively extends the life of your carbide thread milling cutters.

2. Maximum Versatility for Your Workshop

One tool can handle multiple jobs. This helps you reduce inventory costs.

- Universal 60° Geometry: You can use this tool for any 60-degree thread angle.

- Metric and UN Compatible: One cutter works for both Metric ISO threads and UN threads.

- Internal and External: Safely machine both internal and external threads.

- Left and Right Hand: You can create right-hand or left-hand threads simply by changing the CNC program.

Technical Specifications (Customizable)

| M coarse | M fine | Pitch (mm) | d1 (mm) | L1 (mm) | D (mm) | L (mm) | F | Drill dia. (mm) |

|---|---|---|---|---|---|---|---|---|

| M0.6 * 0.15 | 0.15 | 0.43 | 1.2 | 4 | 50 | 3 | 0.45 | |

| M0.8 * 0.2 | 0.2 | 0.55 | 2 | 4 | 50 | 3 | 0.6 | |

| M0.9 * 0.225 | 0.225 | 0.6 | 2 | 4 | 50 | 3 | 0.675 | |

| M1 * 0.25 | 0.25 | 0.73 | 2.3 | 4 | 50 | 3 | 0.75 | |

| M1.2 * 0.25 | 0.25 | 0.92 | 2.8 | 4 | 50 | 3 | 0.95 | |

| M1.4 * 0.3 | 0.3 | 1.05 | 3.2 | 4 | 50 | 3 | 1.1 | |

| M1.6 * 0.35 | 0.35 | 1.21 | 3.5 | 4 | 50 | 3 | 1.25 | |

| M2 * 0.4 | 0.4 | 1.54 | 4.5 | 4 | 50 | 3 | 1.6 | |

| M2.5 * 0.45 | 0.45 | 1.96 | 5.5 | 4 | 50 | 3 | 2.05 | |

| M3 * 0.5 | 0.5 | 2.4 | 7 | 4 | 50 | 3 | 2.5 | |

| M4 * 0.7 | 0.7 | 3.15 | 10 | 4 | 50 | 4 | 3.3 | |

| M5 * 0.8 | 0.8 | 4 | 12 | 4 | 50 | 4 | 4.2 | |

| M5 * 0.8 | 0.8 | 4 | 13 | 6 | 50 | 4 | 4.2 | |

| M6 * 0.5 | 0.5 | 5 | 16 | 6 | 50 | 4 | 5.5 | |

| M6 * 0.75 | 0.75 | 5 | 16 | 6 | 50 | 4 | 5.25 | |

| M6 * 1.0 | 1 | 4.75 | 15 | 6 | 50 | 4 | 5 | |

| M8 * 0.5 | 0.5 | 6 | 16 | 6 | 50 | 4 | 7.5 | |

| M8 * 0.75 | 0.75 | 6 | 16 | 6 | 50 | 4 | 7.25 | |

| M8 * 1.0 | 1 | 6 | 16 | 6 | 50 | 4 | 7 | |

| M8 * 1.25 | 1.25 | 5.95 | 20 | 6 | 60 | 4 | 6.75 | |

| M10 * 0.5 | 0.5 | 8 | 25 | 8 | 60 | 4 | 9.5 | |

| M10 * 0.75 | 0.75 | 8 | 25 | 8 | 60 | 4 | 9.25 | |

| M10 * 1.0 | 1 | 8 | 25 | 8 | 60 | 4 | 9 | |

| M10 * 1.25 | 1.25 | 8 | 25 | 8 | 60 | 4 | 8.75 | |

| M10 * 1.5 | 1.5 | 7.9 | 25 | 8 | 60 | 6 | 8.5 | |

| M12 * 0.5 | 0.5 | 10 | 30 | 10 | 75 | 5 | 11.5 | |

| M12 * 0.75 | 0.75 | 10 | 30 | 10 | 75 | 5 | 11.25 | |

| M12 * 1.0 | 1 | 10 | 30 | 10 | 75 | 5 | 11 | |

| M12 * 1.25 | 1.25 | 10 | 30 | 10 | 75 | 5 | 10.75 | |

| M12 * 1.5 | 1.5 | 10 | 30 | 10 | 75 | 5 | 10.5 | |

| M12 * 1.75 | 1.75 | 9.9 | 30 | 10 | 75 | 6 | 10.25 | |

| M14 * 1.0 | 1 | 12 | 35 | 12 | 75 | 5 | 13 | |

| M14 * 1.5 | 1.5 | 12 | 35 | 12 | 75 | 5 | 12.5 | |

| M14 * 2.0 | 2 | 11.8 | 35 | 12 | 75 | 6 | 12 | |

| M16 * 1.0 | 1 | 14 | 40 | 16 | 75 | 5 | 15 | |

| M16 * 1.5 | 1.5 | 14 | 40 | 16 | 75 | 5 | 14.5 | |

| M16 * 2.0 | 2 | 13.8 | 40 | 16 | 75 | 6 | 14 | |

| M18 * 1.0 | 1 | 16 | 45 | 16 | 75 | 5 | 17 | |

| M18 * 1.5 | 1.5 | 16 | 45 | 16 | 75 | 5 | 16.5 | |

| M18 * 2.5 | 2.5 | 15.3 | 45 | 16 | 75 | 6 | 15.5 | |

| M20 * 1.0 | 1 | 18 | 50 | 20 | 90 | 5 | 19 | |

| M20 * 1.5 | 1.5 | 18 | 50 | 20 | 90 | 5 | 18.5 | |

| M20 * 2.5 | 2.5 | 17.3 | 50 | 20 | 90 | 6 | 17.5 | |

| M22 * 1.0 | 1 | 20 | 55 | 20 | 90 | 5 | 21 | |

| M22 * 1.5 | 1.5 | 20 | 55 | 20 | 90 | 5 | 20.5 | |

| M22 * 2.5 | 2.5 | 19.3 | 55 | 20 | 90 | 6 | 19.5 | |

| M24 * 1.0 | 1 | 22 | 60 | 24 | 90 | 5 | 23 | |

| M24 * 1.5 | 1.5 | 22 | 60 | 24 | 90 | 5 | 22.5 | |

| M24 * 3.0 | 3 | 20.7 | 60 | 24 | 90 | 6 | 21 | |

| M27 * 1.0 | 1 | 25 | 65 | 24 | 90 | 5 | 26 | |

| M27 * 1.5 | 1.5 | 25 | 65 | 24 | 90 | 5 | 25.5 | |

| M27 * 3.0 | 3 | 23.7 | 65 | 24 | 90 | 6 | 24 | |

| M30 * 1.0 | 1 | 28 | 70 | 24 | 90 | 5 | 29 | |

| M30 * 1.5 | 1.5 | 28 | 70 | 24 | 90 | 5 | 28.5 | |

| M30 * 3.5 | 3.5 | 26.2 | 70 | 24 | 90 | 6 | 26.5 | |

| M33 * 1.5 | 1.5 | 31 | 80 | 32 | 110 | 5 | 31.5 | |

| M33 * 3.5 | 3.5 | 29.2 | 80 | 32 | 110 | 6 | 29.5 | |

| M36 * 1.5 | 1.5 | 34 | 85 | 32 | 110 | 5 | 34.5 | |

| M36 * 4.0 | 4 | 31.7 | 85 | 32 | 110 | 6 | 32 |

Other Minnexon Thread Milling Solutions

If you have different production needs, check out our full range of CNC thread mills:

Industry Applications

Our high-performance thread mills are trusted by manufacturers in critical sectors:

- Medical Industry: Machining titanium bone screws, dental implants, and surgical instruments.

- Aerospace: Creating precise threads in engine components, turbine blades, and landing gear.

- Electronics: Machining Kovar housings for glass-to-metal seals.

- Energy Sector: Processing heat-resistant valves and pumps made from nickel alloys.

Why Choose Minnexon?

We offer benefits that matter to both engineers and purchasing managers.

- Large Stock & Global Shipping: We keep a massive inventory. We provide fast shipping worldwide to keep your machines running.

- Factory Direct Pricing: You buy directly from the manufacturer. This guarantees the best price for premium carbide tools.

- 100% Quality Inspection: Every tool undergoes strict optical inspection before shipment. We guarantee zero defects.

- Custom Tool Services: Do you need a special size? We support custom carbide tool manufacturing. Our lead time is only 7 to 10 days.

Ready to Eliminate Machining Headaches?

Stop worrying about broken taps and poor finishes. Upgrade to Minnexon Single-Form Thread Mills and experience the difference in your titanium and alloy machining.

Would you like a free quote or technical advice for your specific print?

Contact our engineering team today or request our latest digital catalog. We are ready to assist you.

Related products

Get in Touch

We will provide you with feedback within 24 hours.