Solid Carbide Thread Mills Manufacturer

Thread Mills: Direct Factory Price. Expert Support.

Cost Control Meets Certification. Purchase Tolerance-Certified cutters at true factory pricing, and immediately consult with the application specialists who designed them. The best tool value achieved without any quality compromise.

92+ HRA Hardness

±0.001mm Tolerance

24 Hr Shipping

Thread Mill Selection by Global Standard

Instantly locate the ideal cutter structure for your needs. Choose your required thread form: ISO Metric (M), UN Unified (UNC/UNF), or Pipe Threads (NPT/BSP) to guarantee perfect thread fit and application success.

Choose Your Thread Mill Structure: Efficiency vs. Versatility

Optimize your machining process by selecting the ideal cutter structure. Match your choice based on required cycle time, material hardness, and machine tool rigidity to unlock maximum efficiency and tool life.

Single-Form Thread Mills

- Ideal for: Small batches, prototyping, and large diameter threads where machine rigidity is limited. One tool covers multiple thread pitches of the same size.

- Benefit: Minimal cutting pressure.

- Key Use: Salvaging broken taps & odd sizes.

Tri-Form Thread Mills

- Ideal for: Deep hole threading, highly abrasive or hard-to-machine materials (Stainless Steel, Inconel). Offers a balance of speed and reduced cutting force.

- Benefit: Optimized for stability and chip control.

- Key Use: Demanding aerospace & medical components.

Multi-Form Thread Mills

- Ideal for: High-volume manufacturing where speed is the priority. These tools mill the complete thread profile in a single helical interpolation for maximum productivity.

- Benefit: Fastest cycle time per hole.

- Key Use: Automotive mass production.

Why Top Machinists Trust Our Tools?

Engineered for Process Security and Performance in Demanding Applications.

1. Uncompromising Geometric Tolerance

Don’t risk scrap parts. Our cutters are ground to strict DIN/ANSI standards with a ± 0.001mm tolerance. This ensures your threads pass Go/No-Go gauge inspection every single time, minimizing rework.

2. 20-Year Expertise in Coating Strategy

We are a dedicated application expert. Through our Strategic Partnership with Balzers Coating Company, we provide specialized composite coating solutions via dedicated R&D for the most difficult-to-machine materials, including Stainless Steel, Titanium Alloys, and High-Nickel Alloys (like Inconel).

Unlike vendors offering one universal option, choosing the correct coating for your material can boost your tool life by 30% to 50%. We maintain inventory of these high-performance composite options for immediate deployment.

3. Eliminate Programming Guesswork

Experience shows 95% of tool failure originates from incorrect feed rates. We provide expert application consultation to ensure you program the optimal parameters. Furthermore, we guide the selection of appropriate cutter structure and length for stability. For example, for materials HRC60, we recommend prioritizing Single-Form or Tri-Form cutters and minimizing tool projection length for maximum rigidity.

Frequently Asked Questions (FAQ)

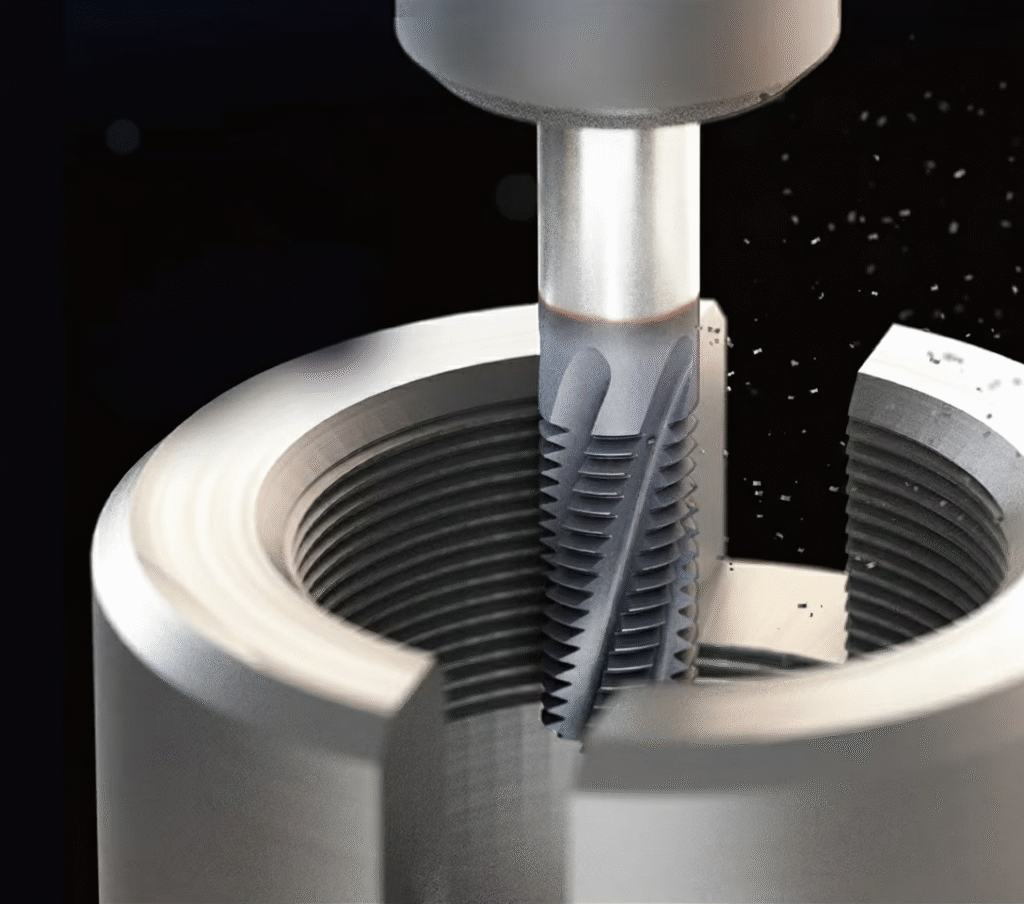

Q: How does a thread mill work?

A: Thread milling is a machining process that generates a thread using a rotating cutter via helical interpolation on a CNC machine. Unlike tapping, where the tap creates the thread in a single, fixed rotation, the thread mill creates the geometry dynamically using simultaneous movement across three axes (X, Y, and Z).

Q: What is the primary advantage of Thread Milling over traditional Tapping?

A: The main advantage is superior Process Security and Quality Control, which drastically reduces risk in high-value manufacturing:

- Part Salvageability: If a thread mill breaks, the workpiece is usually salvageable. A broken tap, conversely, often leads to the scrapping of the entire, expensive part.

- Geometric Control: Thread milling allows for precise adjustment of the final thread size (Pitch Diameter Control) via CNC compensation, guaranteeing strict tolerances that tapping cannot easily match.

- Flexibility: One thread mill can be used to cut various diameters (of the same pitch), reducing tool inventory. They also handle hard materials (up to HRC60) and large, deep threads more reliably than taps.

Q: Can your Solid Carbide Thread Mills process hardened materials (HRC60)?

A: Yes. Our premium substrate and Balzers composite coatings are designed for this. However, this requires expertise: we advise selecting the most rigid Single-Point or Three-Tooth structures and focusing intensely on Tool Projection Length and machine rigidity to prevent brittle fracture.

Q: How quickly can I receive the specialized tools featured?

A: We commit to rapid deployment. Our strategic inventory management ensures that 95% of our standard stock, including high-performance coating options, is processed for shipping within 24 hours. Standard delivery timelines apply thereafter.

Q: How does tool diameter selection impact the process?

A: Generally, selecting the largest diameter cutter that fits your application (i.e., the largest internal diameter of the thread) will enhance stability and rigidity. A stiffer tool is less prone to deflection and vibration, leading to better surface finish and longer tool life.

Get in Touch

We will provide you with feedback within 24 hours.