Metric Carbide Long Straight Flute Tap

- Deep Access: Extra-long overall length designed to reach into deep cavities, pockets, and past fixtures.

- Anti-Vibration: Solid Carbide construction provides high static stiffness, eliminating the “chatter” and tool deflection common with long HSS taps.

- Max Core Strength: The straight flute geometry offers the thickest web diameter, making it the strongest option for long-reach tapping.

- Material Focus: Optimized for short-chipping materials like Cast Iron and Hardened Steel.

Metric Carbide Long Straight Flute Tap

Reach Deeper Without Sacrificing Precision

Machining threads in deep hydraulic manifolds, engine blocks, or complex mold bases presents a unique challenge: Accessibility. Standard length taps simply cannot reach, and using tool extensions often introduces runout and instability.

Minnexon Metric Solid Carbide Long Straight Flute Taps are engineered to bridge this gap. We combine the extended reach of a special tool with the extreme rigidity of Tungsten Carbide, allowing you to tap deep inside cavities where standard tools would fail.

(Don’t need the extra length? View our standard Metric Solid Carbide Straight Flute Taps for general applications.)

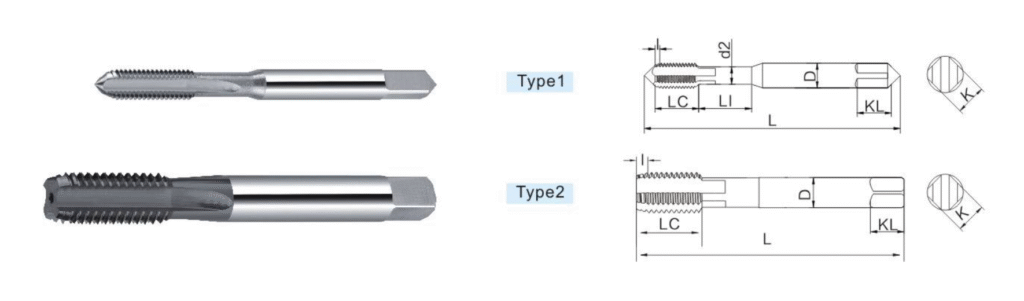

Technical Specifications (Customizable)

| Thread Size | I | L | LC | D | Z | KL | K | L1 | d2 |

|---|---|---|---|---|---|---|---|---|---|

| M3×0.5 | 2.5P | 80 | 4 | 9 | 3 | 5.5 | 3.2 | 8 | 2.4 |

| M4×0.7 | 2.5P | 80 | 5 | 9 | 3 | 6 | 4 | 10 | 3.1 |

| M5×0.8 | 2.5P | 80 | 6 | 12 | 3 | 8 | 4.5 | 12 | 4 |

| M5×0.8 | 2.5P | 100 | 6 | 12 | 3 | 8 | 4.5 | 12 | 4 |

| M6×1 | 2.5P | 80 | 6 | 13 | 3 | 8 | 4.9 | 12 | 4.8 |

| M6×1 | 2.5P | 100 | 6 | 13 | 3 | 8 | 4.9 | 12 | 4.8 |

| M8×1 | 2.5P | 90 | 8 | 16 | 4 | 9 | 6.2 | 24 | 6.3 |

| M8×1.25 | 2.5P | 90 | 8 | 16 | 4 | 9 | 6.2 | 24 | 6.3 |

| M8×1.25 | 2.5P | 100 | 8 | 16 | 4 | 9 | 6.2 | 24 | 6.3 |

| M10×1 | 2.5P | 100 | 10 | 18 | 4 | 11 | 8 | 27 | 8.2 |

| M10×1.25 | 2.5P | 100 | 10 | 18 | 4 | 11 | 8 | 27 | 8.2 |

| M10×1.5 | 2.5P | 100 | 10 | 18 | 4 | 11 | 8 | 27 | 8.2 |

| M12×1.5 | 2.5P | 100 | 9 | 22 | 4 | 10 | 7 | 20 | 8.8 |

| M12×1.75 | 2.5P | 100 | 9 | 22 | 4 | 10 | 7 | 20 | 8.8 |

| M14×1.5 | 2.5P | 110 | 11 | 22 | 4 | 12 | 9 | 20 | 10.8 |

| M14×2 | 2.5P | 110 | 11 | 22 | 4 | 12 | 9 | 20 | 10.8 |

| M16×1.5 | 2.5P | 110 | 12 | 22 | 4 | 13 | 9 | 20 | 11.8 |

| M16×2.0 | 2.5P | 110 | 12 | 22 | 4 | 13 | 9 | 20 | 11.8 |

| M18×1.5 | 2.5P | 110 | 14 | 24 | 4 | 14 | 11 | 20 | 13.8 |

| M18×2.5 | 2.5P | 110 | 14 | 24 | 4 | 14 | 11 | 20 | 13.8 |

The “Wobble” Problem: Why HSS Fails at Length

In physics, as a tool gets longer, it becomes more flexible. A long High-Speed Steel (HSS) tap acts like a spring—it bends under torque. This leads to:

- Chatter Marks: Poor surface finish on the thread.

- Oversized Threads: The tool “whips” around, cutting the hole larger than the gauge limit.

- Snap Breakage: The flexing causes fatigue and eventual snapping deep inside the part.

Geometry: Maximum Core Strength

When a tap is long and thin, structural integrity is paramount. Among all tap geometries, the Straight Flute design leaves the most material in the core (web) of the tap.

- Spiral Flutes cut deep into the core to lift chips.

- Straight Flutes are shallow, preserving the tool’s backbone.

This makes the Long Straight Flute Tap the most robust choice for deep-reach applications in tough materials. It resists torsional twisting better than any other long tap design.

Optimized Applications

This tool is a problem-solver for specific industries:

- Hydraulic Manifolds: Tapping ports deep within recessed blocks.

- Mold & Die Base: Machining guideways or water lines where clearance is tight.

- Automotive: Cylinder block features obstructed by casting walls.

Target Materials (Short-Chipping):

- Grey Cast Iron (GG) & Nodular Iron (GGG)

- High-Strength / Hardened Steels

- Short-chipping Brass & Bronze

(Warning: For deep holes in Aluminum or Stainless Steel where chip evacuation is critical, please consider our Metric Spiral Flute Taps.)

Difficult-to-Machine Materials?

If you are working with hardened steel (HRC 45+) or require absolute thread safety without the risk of tap breakage, consider our Solid Carbide Thread Milling Cutters. Thread mills offer the highest process security for high-value components.

Get in Touch

We will provide you with feedback within 24 hours.