- 2025-11-20

- 0 Comment

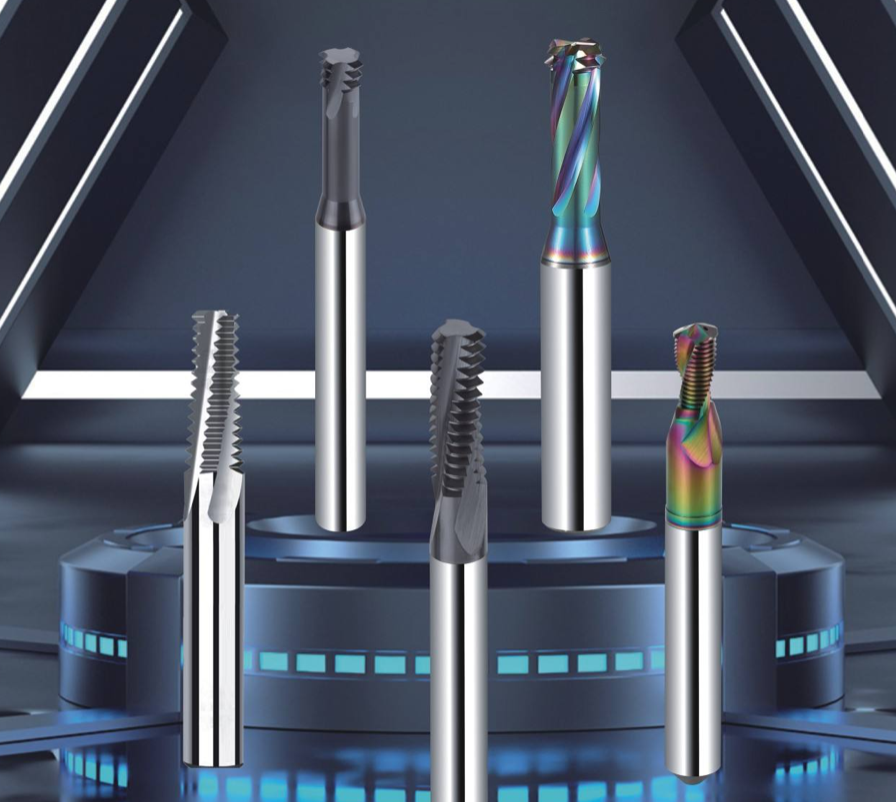

Struggling with Hard or Deep Threads? Discover the Power of Thread Milling Cutters

Thread machining is essential in mechanical manufacturing. Industries like aerospace, automotive parts, and precision molds require high-precision and efficient threads. Traditional taps have limitations in certain scenarios. Thread milling cutters solve these challenges with higher precision, longer tool life, and better efficiency.

1. Common Challenges in Thread Machining

Accuracy and Stability

Traditional taps may cause runout or inconsistent threads in high-hardness materials, deep holes, or complex threads.

Thread milling cutter advantage: CNC-controlled tool paths achieve ±0.01 mm accuracy.

Tool Life and Maintenance

Taps wear or break quickly in batch production.

Thread milling cutter advantage: Carbide construction with wear-resistant coatings extends tool life.

Machining Efficiency

Traditional taps require multiple passes or frequent tool changes.

Thread milling cutter advantage: Form threads in one or few passes, ideal for multi-size or complex parts.

Material Compatibility

Hard steels, titanium alloys, and special threads challenge traditional taps.

Thread milling cutter advantage: Machining metric, inch, trapezoidal, and custom threads with flexibility.

2. Thread Milling Cutter Selection Guide

Material and Coating

| Material | Recommended Coating |

|---|---|

| Aluminum, Copper | Uncoated / TiN |

| Stainless Steel, Carbon Steel | TiAlN |

| Titanium Alloy, Hard Steel | AlTiN / CVD |

Thread Depth and Tooth Type

| Thread Depth | Recommended Tooth Type | Notes |

|---|---|---|

| Shallow / Small Diameter | Full-profile cutter | High efficiency |

| Medium / Standard Depth | Three-tooth cutter | Balanced cutting force & speed |

| Deep / Hard Material | Single-tooth cutter | Reduces cutting load, improves precision |

| Tip | Deep threads can still use full-profile or three-tooth cutters with rigid machines |

Thread Type and Size

- Metric, inch, trapezoidal, or special threads

- Choose cutter diameter and tooth type based on CNC program and thread size

3. Classic Application Cases

1. High-Hardness Deep Threads – Titanium Aerospace Bracket M8×1.25

- Component: Aerospace bracket, wall 6 mm, thread depth 20 mm

- Challenge: Deep threads, high hardness, traditional taps break easily

- Solution: Single-form or Multi-form AlTiN-coated cutter, CNC 1-2 passes

- Result: ±0.01 mm precision, Ra ≤ 0.8 μm, tool life ×3

2. Medium Hole Batch Threads – Stainless Steel Engine Bracket M10×1.5

- Component: Engine bracket, depth 12 mm, batch 500

- Challenge: Multi-size threads, traditional taps wear fast

- Solution: Tri-form TiAlN-coated cutter, CNC switches sizes quickly

- Result: +30% production efficiency, smooth threads, no burrs

3. Shallow High-Precision Threads – Aluminum Mold M6×1.0

- Component: Aluminum mold, depth 5 mm

- Challenge: High surface finish, small batch

- Solution: Multi-form uncoated cutter, one-pass machining

- Result: Ra ≤ 0.6 μm, machining time -40%

Frequently Asked Questions (FAQ)

Q1: Are thread milling cutters suitable for all materials?

A: Yes. Aluminum, copper, stainless steel, titanium alloy, and high-hardness steel can be machined. Selecting the proper coating improves tool life and machining quality.

Q2: Must deep threads use single-tooth cutters?

A: Not always. Single-tooth cutters reduce cutting load for deep or hard threads, but full-profile or three-tooth cutters can also machine deep threads efficiently with rigid machines.

Q3: What are the advantages over traditional taps?

A: Thread milling cutters are more stable in hard materials and deep threads, achieve high precision and long life, and are ideal for CNC automated production.

Q4: Can one cutter handle multiple thread sizes?

A: Generally yes, for standard ranges. Extreme sizes may need dedicated cutters.

Q5: How to extend cutter life?

- Choose the correct coating and tooth type

- Control feed, speed, and coolant

- Optimize CNC tool paths

- Inspect and replace worn tools regularly

Q6: What are typical processing parameters for thread milling cutters?

A: For medium-hard steels and standard threads (e.g., M10×1.5):

- Spindle speed: 3000–3500 rpm

- Feed per tooth: 0.03–0.08 mm/tooth

- Axial depth of cut: 0.5–1.5 mm per pass

These values are reference ranges. Actual parameters should be adjusted based on machine rigidity, material hardness, and tool coating for optimal performance.