- 2025-05-10

- 0 Comment

From Raw Crystal to Luxury Timepiece: How Sapphire Watch Cases Are Made From 0 to 1

A behind-the-scenes look at the complete sapphire watch case production process—from crystal growth to final polishing.

Step 1: Growing the Synthetic Sapphire Crystal

The journey of every sapphire watch case begins in the lab—not in the mine. Synthetic sapphire is created through the Kyropoulos or Verneuil method using pure aluminum oxide (Al₂O₃), grown into large boules under extreme heat and pressure.

Purity: >99.99% Al₂O₃

Growth duration: 2–4 weeks

Boules size: Up to 45 kg

Color doping: Add elements like Cr, Ti, Fe, Ni to create blue, pink, yellow, green, and other hues

Once cooled and stress-relieved, the sapphire boule is ready for slicing.

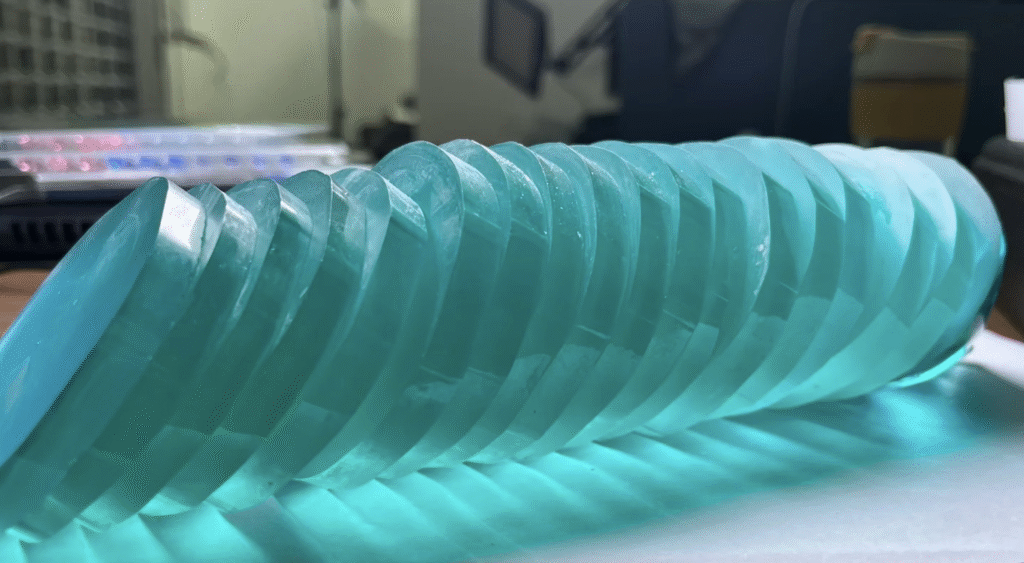

Step 2: Rough Cutting & Pre-Shaping

The solid sapphire boules are sliced into blocks using:

Diamond wire saws

Laser cutting for fine pre-forms

Waterjet or ultrasonic machining for rough outer contours

At this stage, tolerances are wide, but internal stress management is critical to prevent future cracking.

Step 3: CNC Machining the Watch Case Geometry

Using 5-axis CNC machining centers, the sapphire block is milled into its final form. This stage is the heart of the process.

Machine tools: PCD tools, diamond-coated end mills

Tolerance: ±0.005 mm

Cutting speed: Ultra-low to prevent chipping

Coolant: Water or oil mist to manage heat

Typical parts: Case middle, bezel, caseback, crown guards

Special attention is given to hole drilling for screws, gaskets, or mechanical parts, often requiring laser-assisted drilling.

Step 4: Color Enhancement (Optional)

For colored sapphire watch cases, coloration is achieved during crystal growth—but further enhancement may include:

Thermal treatment to intensify tone

UV filtering coating to preserve color

Chemical etching for anti-reflection

Uniformity of color across batches is critical for brand consistency.

Step 5: Optical Polishing & Finishing

Polishing sapphire is both an art and science. The aim is to achieve a mirror-like finish with zero distortion and minimal haze.

Diamond slurry polishing

Step polishing to avoid edge rounding

Ra < 0.02 µm finish

Manual inspection under polarized light

A single case can take up to 40 hours of polishing time depending on geometry and clarity requirements.

Step 6: Assembly Preparation

Once machined and polished, the sapphire parts are ready for:

Gasket seating surface checks

Waterproof pressure testing

Ultrasonic cleaning

Coating (e.g., anti-reflective, anti-fingerprint)

At this point, the sapphire case is ready to meet metal components or mechanical movements.

Challenges & What Sets Minnexon Apart

Producing sapphire watch cases is notoriously difficult, with failure rates of up to 30% in unoptimized environments. Key challenges include:

Cracking during machining or post-polish

Color mismatch

Micron-level tolerance misalignment

At Minnexon, we overcome these with:

In-house crystal growth and coloring expertise

Precision 5-axis sapphire CNC systems

Advanced polishing automation & inspection

Experience serving Swiss and French luxury brands