±0.003 mm Tolerance CNC Machining for Alumina Ceramics, Silicon Carbide

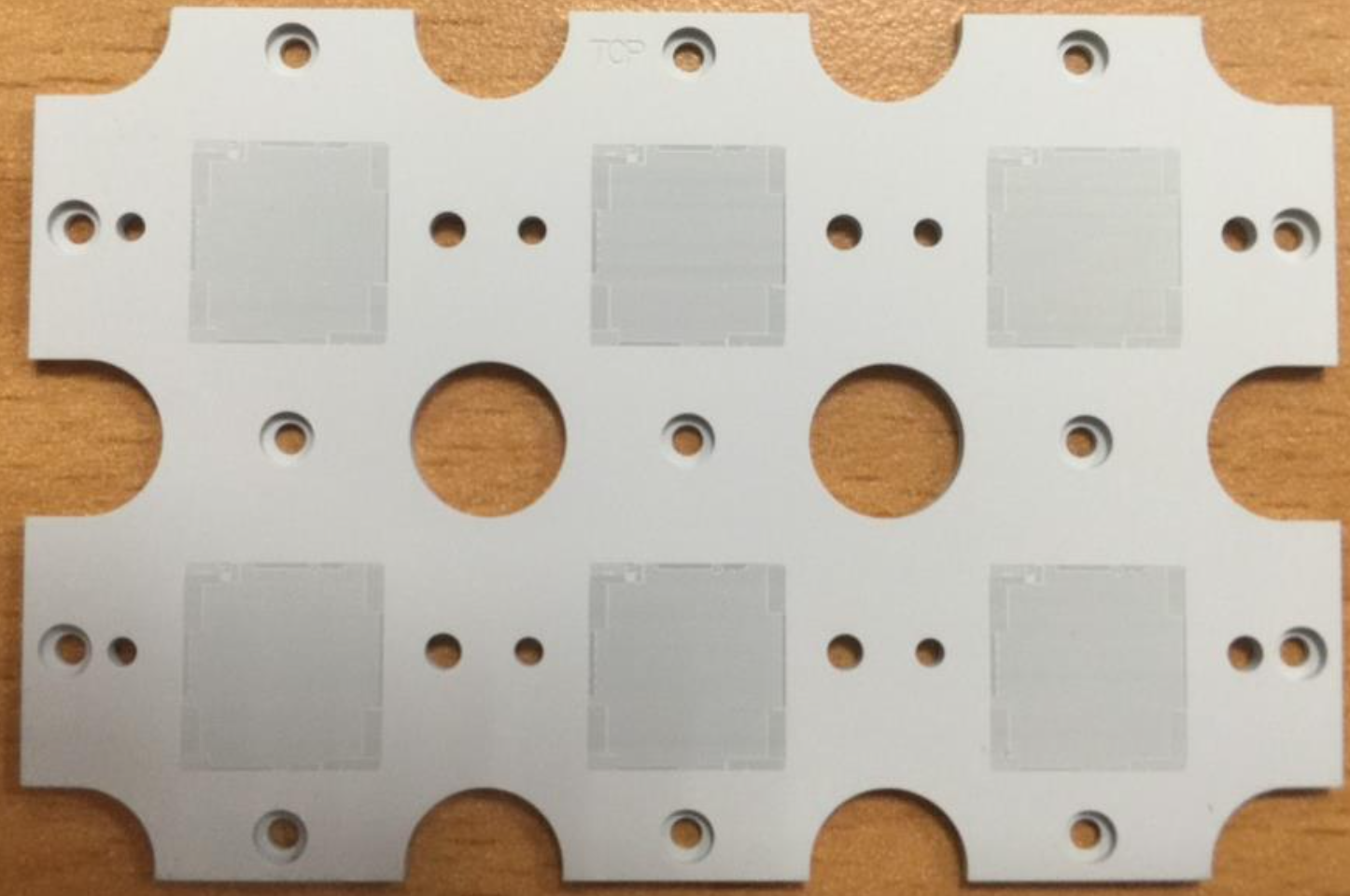

At Minnexon, we specialize in ultra-precision CNC machining for some of the hardest and most demanding engineering materials in the world — including alumina ceramic, single-crystal alumina (sapphire), silicon carbide ceramic, and single-crystal silicon carbide (moissanite).

With micro-hole drilling down to 0.025 mm and tolerances as tight as ±0.003 mm, we deliver components for industries where precision, material performance, and reliability are non-negotiable.

Materials We Machine

Our advanced CNC, laser, and ultrasonic machining systems are capable of processing materials with extreme hardness:

| Material | Composition | Mohs Hardness | Key Properties |

|---|---|---|---|

| Alumina Ceramic | Al₂O₃ | ~9 | High hardness, excellent wear resistance, electrical insulation |

| Sapphire (Single-Crystal Alumina) | Al₂O₃ (single crystal) | 9 | Extreme scratch resistance, optical transparency, high thermal conductivity |

| Silicon Carbide Ceramic | SiC | 9–9.5 | Exceptional thermal conductivity, chemical resistance, and hardness |

| Moissanite (Single-Crystal Silicon Carbide) | SiC (single crystal) | 9.25 | Ultra-high hardness, thermal stability, and optical clarity |

Our capability to consistently machine materials close to diamond in hardness (Mohs 9–9.5) makes Minnexon a trusted partner for industries that require precision in ultra-hard substrates.

Technical Capabilities

| Specification | Value |

|---|---|

| Minimum Hole Diameter | 0.025 mm (25 μm) |

| Maximum Hole Count per Workpiece | 35,004 |

| Tolerance – Entrance Side | ±0.003 mm |

| Tolerance – Exit Side | ±0.005 mm |

| Maximum Depth by Hole Diameter | See Table Below |

| Minimum Hole Spacing | 0.010 mm |

Maximum Depth by Hole Diameter:

| Hole Diameter | Maximum Depth | Depth/Diameter Ratio |

|---|---|---|

| 25 μm | 0.20 mm | 8:1 |

| 30 μm | 0.30 mm | 10:1 |

| 35 μm | 0.35 mm | 10:1 |

| 40–50 μm | Calculated | 10–16:1 |

| ≥ 55 μm | Calculated | 12–16:1 |

Why Choose Minnexon for Ultra-Hard Material Machining?

Extreme Precision: ±0.003 mm / ±0.005 mm tolerance control

Ultra-Hard Material Expertise: Sapphire, silicon carbide, alumina ceramics, and moissanite machining

High Production Capacity: Up to 35,004 holes per workpiece

Micro-Scale Capability: Down to 25 μm holes with ultra-close spacing

Material-Specific Engineering: Optimized processes for each material’s thermal, optical, and mechanical properties

Industries We Serve

Electronics & Semiconductors: High-density interconnects, micro-vias, RF and microwave components

Medical Devices: Microfluidic channels, precision optical windows, and implant components

Aerospace & Defense: Radar substrates, high-temperature insulators, optical targeting components

Optics & Photonics: Precision apertures, laser windows, optical domes

Other solutions

High-precision Stainless Steel CNC Machining

Have a

project in

mind?

Get in Touch

We will provide you with feedback within 24 hours.