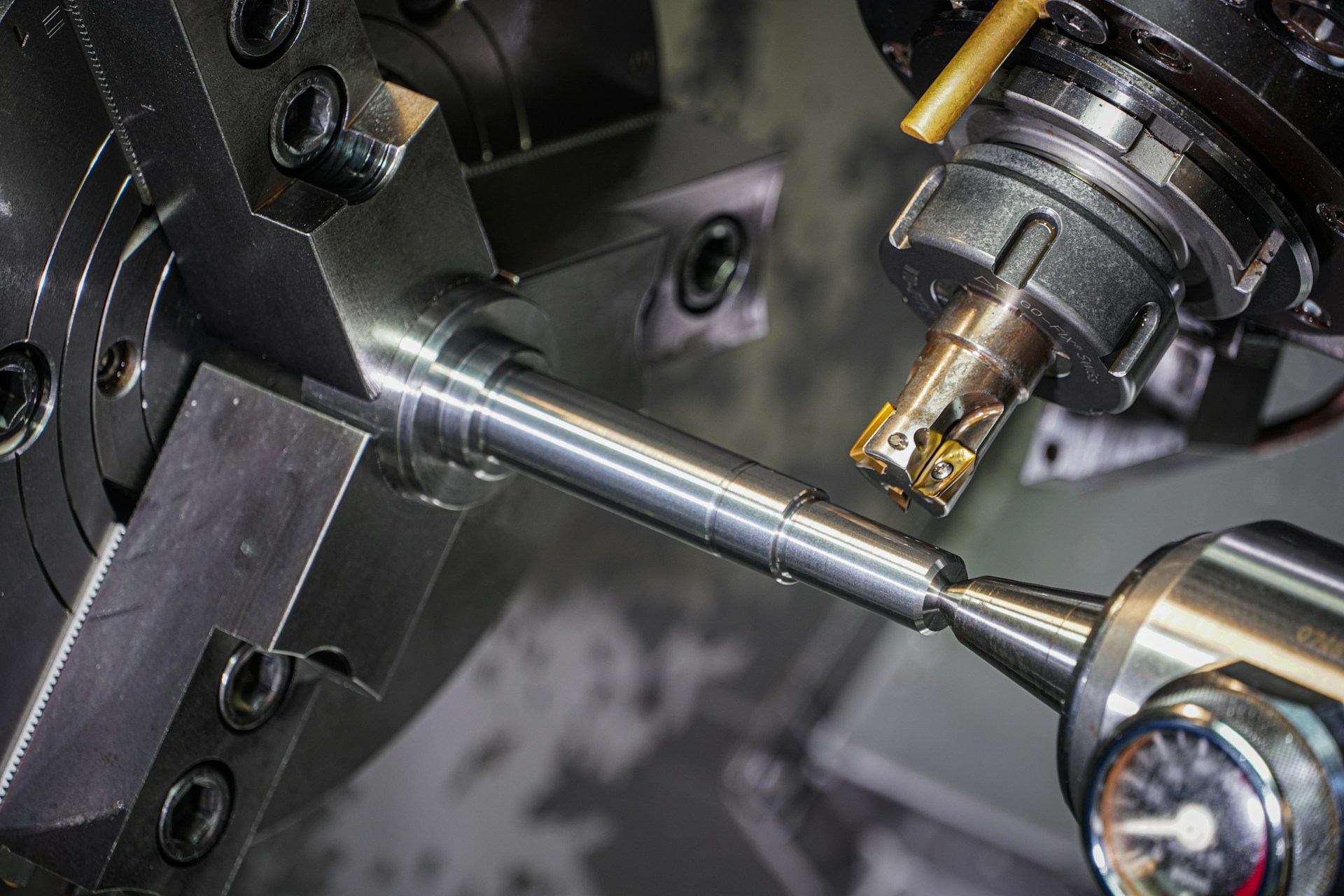

Stainless Steel CNC Machining

Stainless Steel CNC Machining — Precision Parts Without the Headaches

Machining stainless steel is never as straightforward as it looks on paper. Whether you're dealing with work-hardening, burr control, or tolerance drift during finishing, stainless presents unique challenges that can derail tight production schedules and compromise part quality.

At our facility, we specialize in the CNC machining of precision stainless steel parts, including complex geometries, thin-walled features, and demanding tolerance requirements. With deep expertise and a problem-solving mindset, we help engineers turn difficult designs into high-performance components—reliably and repeatably.

Common Stainless Machining Challenges We Solve

If your current supplier keeps blaming the material for inconsistent results, it’s time to talk to someone who actually understands stainless.

Materials We Work With

We routinely machine parts in:

Part Types & Applications

Surgical & dental components

Industrial nozzles and housings

Watch & luxury hardware

Threaded inserts, sleeves, valves

Robotic end-effectors and jigs

High-pressure fittings and flow control parts

Whether it's a one-off prototype or low-volume production, we handle parts that others avoid—because performance matters.

Why Engineers Trust Us

±0.002mm tolerance capability on critical dimensions

Expert in burr control and surface finishing for stainless steel

In-house tooling optimization for form stability and tool life

Real-time quality checks using CMM and profile scanners

Fast feedback loop from DFM suggestions to part delivery

We don’t just run your drawings—we refine, adapt, and manufacture with intent.

Other solutions

Have a

project in

mind?

Get in Touch

We will provide you with feedback within 24 hours.