BSPP/BSPT Single-Form 55 Degree Thread Mill | Solid Carbide Thread Milling Cutter

- Selected solid carbide tungsten steel material, manufactured using German Walter equipment.

- Multiple coating options available, including uncoated, AlTiN, TiAlN, and DLC coatings.

- Suitable for machining 55° BSPP/PT threads, with a wide machining range capable of handling various thread sizes and pitches.

- Applicable for both left-hand and right-hand threads, as well as internal and external threads.

Product Overview

The G / RC Single-Tooth Thread Mill is a solid carbide CNC threading tool designed for high-precision pipe threads. Its 55° thread angle makes it versatile for both:

G / BSPP / PF parallel threads (straight threads)

RC / BSPT tapered threads (requires pre-machined tapered hole)

Internationally, G threads are also called BSPP, PF, ISO 228, while RC threads are also known as BSPT, PT, ISO 7/1 tapered pipe threads.

The single-tooth universal profile design allows one tool to machine a range of pitches, providing high flexibility, cost efficiency, and reduced tooling inventory.

Key Features

Material: Solid tungsten carbide for maximum durability and rigidity

Thread Standard: Supports G/BSPP/PF (parallel) and RC/BSPT/PT (tapered) threads

Universal Pitch Range: One tool can cover multiple thread pitches

Threading Flexibility: Can machine internal & external threads, left-hand & right-hand threads

CNC Optimized: High-speed, high-precision milling for professional CNC centers

Cost-Effective: Versatile single-tooth design reduces the need for multiple tools

Material & Coating Recommendations

| Workpiece Material | Recommended Coating | Benefits |

|---|---|---|

| Copper / Aluminum | DLC / TiB₂/ no coating | Prevents built-up edge, smooth chip evacuation |

| 45# Steel / Carbon Steel | TiN / TiCN | Balanced hardness and toughness |

| Stainless Steel | AlTiN / AlCrN | High oxidation resistance, long tool life |

| P20 Tool Steel | TiCN / AlTiN | Enhanced wear resistance |

| Cast Iron | TiN / TiCN | Improves edge stability, reduces chipping |

| Titanium Alloys | AlTiN / AlCrN | Handles high cutting temperatures |

| Heat-Resistant Alloys | AlCrN / AlTiSiN | Maximum heat resistance, extended service life |

Tip: Choosing the right coating is crucial for tool life and machining efficiency.

Machining Tips

For G / BSPP / PF parallel threads (straight): Drill a straight hole to the correct minor diameter before thread milling.

For RC / BSPT tapered threads: Pre-machine the hole to match the taper of the thread. The single-tooth thread mill then cuts the thread accurately.

💡 Use a stable CNC program with correct interpolation settings to achieve best accuracy and surface finish.

Single-Tooth vs Full-Form Thread Mills

| Feature | Single-Tooth Thread Mill | Full-Form Thread Mill |

|---|---|---|

| Pitch Range | One tool can cut multiple pitches | Fixed pitch size only |

| Cost Efficiency | Lower cost, fewer tools needed | Higher cost, requires multiple tools |

| Cycle Time | Longer (threads cut tooth by tooth) | Faster (multiple teeth cut simultaneously) |

| Flexibility | Highly versatile, ideal for small batches | Best for mass production of one pitch |

| Tool Inventory | Minimal | Larger inventory required |

| Thread Quality | Excellent if programmed well | Very consistent for high-volume production |

Applications

Aerospace & Aviation: Hydraulic and fuel line fittings requiring high-precision threads.

Automotive: Engine components, transmission parts, and brake systems.

Oil & Gas: Tapered and parallel pipe connections for valves, pipelines, and joints.

Hydraulics & Pneumatics: Cylinders, pumps, and connectors with internal/external threads.

General Engineering & Machinery: Custom machinery, molds, and equipment assemblies needing accurate threaded connections.

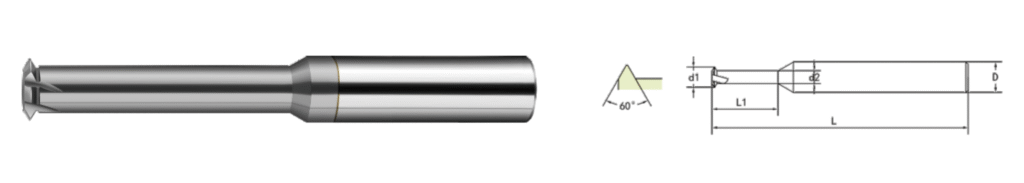

Technical Specifications (Customizable)

| Applicable thread/A55° | P | d1/mm | L1/mm | D/mm | L/mm | F |

|---|---|---|---|---|---|---|

| G/RC 1/16-28 & 1/8-28 | 0.5-1.0 | 4 | 12 | 4 | 50 | 4 |

| G/RC 1/8-28 | 0.5-1.25 | 4.6 | 16 | 6 | 50 | 4 |

| G/RC 1/8-28 | 0.5-1.25 | 4.8 | 16 | 6 | 50 | 4 |

| G/RC 1/8-28 | 0.5-1.25 | 5 | 16 | 6 | 50 | 4 |

| G/RC 1/8-28 | 0.5-1.25 | 6 | 16 | 6 | 50 | 4 |

| G/RC 1/4-19 & 3/8-19 | 1.0-2.0 | 8 | 25 | 8 | 60 | 4 |

| G/RC 1/4-19 & 3/8-19 | 1.0-2.0 | 8 | 30 | 8 | 75 | 4 |

| G/RC 1/4-19 & 3/8-19 | 1.0-2.0 | 8 | 30 | 8 | 100 | 4 |

| G/RC 1/2-14 & 3/4-14 | 1.0-2.5 | 10 | 30 | 10 | 75 | 5 |

| G/RC 1-11 & 2-11 | 2.0-2.5 | 12 | 35 | 12 | 75 | 5 |

| G/RC 1-11 & 2-11 | 2.0-3.0 | 15.95 | 45 | 16 | 100 | 6 |

| G/RC 1/8-28 (R corner) | 0.5-1.25 | 5.95 | 15 | 6 | 50 | 4 |

| G/RC 1/4-19 & 3/8-19 (R corner) | 1.0-2.0 | 7.95 | 25 | 8 | 60 | 4 |

| G/RC 1/2-14 & 3/4-14 (R corner) | 1.0-2.5 | 9.95 | 30 | 10 | 75 | 4 |

| G/RC 1-11 & 2-11 (R corner) | 2.0-2.5 | 11.95 | 35 | 12 | 75 | 4 |

Frequently Asked Questions (FAQ)

Q1: Should I choose a single-tooth or full-form thread mill?

Single-tooth thread mill: Flexible, can cover multiple pitches. Ideal for small-batch production or universal use.

Full-form thread mill: Faster for high-volume production, very consistent thread quality.

Q2: Do I need to pre-drill the hole before using a single-tooth thread mill?

G / BSPP / PF threads: Drill a straight hole of correct minor diameter.

RC / BSPT / PT threads: Pre-machine a tapered hole to match the thread profile before milling.

Q3: Can I use the same tool for left-hand and right-hand threads?

Yes. The single-tooth thread mill supports both directions.

Related products

-

NPTF Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

NPT Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

BSPP(G) Multi-Form 55 degree Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

BSPT Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more

Get in Touch

We will provide you with feedback within 24 hours.