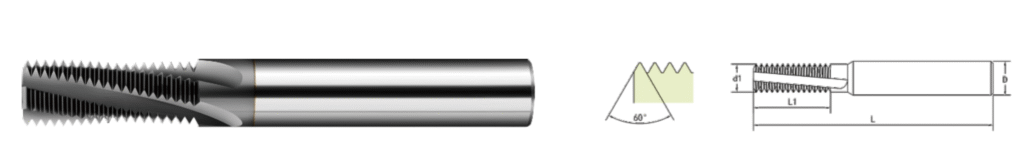

Metric Multi-Form Thread Milling Cutter | Solid Carbide Thread Mill

Explore solid carbide multi-form thread milling cutters for precise internal and external 60° metric threads.

- Available in uncoated, AlTiN, TiAlN, and DLC coatings.

- Supports both right-hand and left-hand threads

- High performance at competitive prices.

Solid Carbide Metric Multi-Form Thread Milling Cutter

The Minnexon Metric Multi-Form Thread Milling Cutter represents the standard of precision. We select high-quality solid carbide tungsten steel as our raw material. To ensure consistent geometry and sharp cutting edges, we produce every tool using advanced German Walter equipment.

This rigorous manufacturing process guarantees that our thread mills meet the strict demands of modern CNC machining.

Customized Coating Solutions

We understand that one coating does not fit all applications. Machining aluminum requires a different approach than machining heat-resistant superalloys. Unlike competitors who use a single generic coating, we offer tailored options to maximize tool life.

- Uncoated / DLC: Ideal for non-ferrous materials like aluminum. It prevents the material from sticking to the cutter.

- AlTiN / TiAlN: Recommended for stainless steel, cast iron, and general steels. These coatings provide excellent thermal stability.

- Specialized Coatings: We provide specific solutions for difficult materials like titanium alloys and high-temperature alloys.

Please consult our technical team to select the perfect coating for your workpiece.

Technical Specifications (Customizable)

| M coarse | M fine | Pitch | d1/mm | L1/mm | D/mm | L/mm | Flutes | Drill dia./mm |

|---|---|---|---|---|---|---|---|---|

| M1.6×0.35 | 0.35 | 1.2 | 3.5 | 4 | 50 | 3 | 1.25 | |

| M2×0.4 | 0.4 | 1.54 | 5 | 4 | 50 | 3 | 1.6 | |

| M2.5×0.45 | 0.45 | 1.96 | 6 | 4 | 50 | 3 | 2.05 | |

| M3×0.5 | 0.5 | 2.4 | 7.5 | 4 | 50 | 3 | 2.5 | |

| M3.5×0.6 | 0.6 | 2.75 | 8.5 | 4 | 50 | 3 | 2.9 | |

| M4×0.5 | 0.5 | 3 | 8 | 4 | 50 | 3 | 3.5 | |

| M4×0.7 | 0.7 | 3.15 | 10 | 4 | 50 | 3 | 3.3 | |

| M4.5×0.75 | 0.75 | 3.4 | 9 | 4 | 50 | 3 | 3.75 | |

| M5×0.5 | 0.5 | 3.9 | 12 | 4 | 50 | 3 | 4.5 | |

| M5×0.8 | 0.8 | 3.95 | 12 | 4 | 50 | 3 | 4.2 | |

| M5×0.8 | 0.8 | 3.9 | 13 | 6 | 50 | 3 | 4.2 | |

| M6×0.5 | 0.5 | 4.8 | 13 | 6 | 50 | 3 | 5.5 | |

| M6×0.75 | 0.75 | 3.9 | 12 | 4 | 50 | 3 | 5.25 | |

| M6×1.0 | 1 | 3.95 | 12 | 4 | 50 | 3 | 5 | |

| M6×1.0 | 1 | 4.75 | 13 | 6 | 50 | 3 | 5 | |

| M8×0.5 | 0.5 | 5.9 | 16 | 6 | 60 | 3 | 7.5 | |

| M8×0.75 | 0.75 | 5.95 | 18 | 6 | 60 | 3 | 7.25 | |

| M8×1.0 | 1 | 5.95 | 15 | 6 | 60 | 3 | 7 | |

| M8×1.25 | 1.25 | 5.9 | 18 | 6 | 60 | 3 | 6.75 | |

| M10×0.5 | 0.5 | 7.9 | 20 | 8 | 65 | 4 | 9.5 | |

| M10×0.75 | 0.75 | 7.9 | 22 | 8 | 65 | 4 | 9.25 | |

| M10×1.0 | 1 | 7.95 | 22 | 8 | 65 | 4 | 9 | |

| M10×1.25 | 1.25 | 7.9 | 20 | 8 | 65 | 4 | 8.75 | |

| M10×1.5 | 1.5 | 7.7 | 22 | 8 | 65 | 4 | 8.5 | |

| M12×0.5 | 0.5 | 9.95 | 25 | 10 | 75 | 4 | 11.5 | |

| M12×0.75 | 0.75 | 9.95 | 20 | 10 | 75 | 4 | 11.25 | |

| M12×1.0 | 1 | 9.9 | 28 | 10 | 75 | 4 | 11 | |

| M12×1.25 | 1.25 | 9.9 | 25 | 10 | 75 | 4 | 10.75 | |

| M12×1.5 | 1.5 | 9.4 | 24 | 10 | 75 | 4 | 10.5 | |

| M12×1.75 | 1.75 | 9.5 | 25 | 10 | 75 | 4 | 10.25 | |

| M14×0.5 | 0.5 | 11.9 | 30 | 12 | 75 | 4 | 13.5 | |

| M14×1.0 | 1 | 11.9 | 30 | 12 | 75 | 4 | 13 | |

| M14×1.5 | 1.5 | 9.9 | 25 | 10 | 75 | 4 | 12.5 | |

| M14×1.5 | 1.5 | 11.2 | 30 | 12 | 75 | 4 | 12.5 | |

| M14×2.0 | 2 | 9.9 | 30 | 10 | 75 | 4 | 12 | |

| M14×2.0 | 2 | 11.2 | 30 | 12 | 75 | 4 | 12 | |

| M16×1.5 | 1.5 | 12 | 30 | 12 | 75 | 4 | 14.5 | |

| M16×2.0 | 2 | 11.9 | 30 | 12 | 75 | 4 | 14 | |

| M18×2.0 | 2 | 13.9 | 33 | 14 | 100 | 4 | 16 | |

| M18×2.5 | 2.5 | 13.9 | 33 | 14 | 100 | 5 | 15.5 | |

| M20×1.5 | 1.5 | 15.95 | 40 | 16 | 100 | 5 | 18.5 | |

| M20×1.0 | 1 | 16 | 40 | 16 | 100 | 5 | 19 | |

| M20×2.0 | 2 | 15.95 | 40 | 16 | 100 | 5 | 18 | |

| M20×2.5 | 2.5 | 15.9 | 40 | 16 | 100 | 5 | 17.5 | |

| M24×3.0 | 3 | 15.9 | 40 | 16 | 100 | 5 | 21 | |

| M30×2.0 | 2 | 20 | 40 | 20 | 100 | 5 | 28 | |

| M30×3.5 | 3.5 | 15.9 | 40 | 16 | 100 | 5 | 26.5 | |

| M36×4.0 | 4 | 20 | 40 | 20 | 100 | 5 | 32 |

Why choose Minnexon thread mills?

Robust Tool Design

Our engineers focused on durability when designing this thread milling cutter. The tool features a professional forming groove design with a large core diameter.

This structural advantage offers several benefits:

- High Rigidity: The large core reduces tool deflection during the cut.

- Breakage Resistance: It significantly lowers the risk of the tool breaking inside the hole.

- Extended Life: The design provides superior resistance to wear and chipping.

Maximum Versatility

A major advantage of our solid carbide thread mill is its flexibility. A single tool can handle multiple threading operations. You can use this cutter to produce both internal and external threads.

Furthermore, the same tool can cut both right-hand and left-hand threads. You simply change the rotational direction and the tool path in your CNC program. This reduces your inventory costs effectively.

If your project requires American standards, please check our UN Multi-Form Thread Mills. For pipe applications, visit our NPT Thread Mills page.

Accuracy for Every Industry

From aerospace components to medical devices, our CNC thread milling tools deliver precise ISO Metric threads. The combination of German manufacturing precision and material-specific coatings ensures you get the best cost-per-thread in the industry.

How to use Thread Milling Cutters

Thread Mills Speeds & Feeds

Getting the best performance requires correct data. Because our tools use premium tungsten steel and specialized coatings, they can run at higher parameters than standard tools.

However, chip evacuation is critical. When machining deep holes or materials like stainless steel, ensure you have adequate coolant pressure. This flushes chips away from the cutting zone and prevents recutting. We provide thread milling speeds and feeds to help you optimize your cycle time.

Material Compatibility

- 45# medium carbon steel

- Stainless steels (304, 316)

- P20 pre-hardened mold steel

- Gray and ductile cast iron

- Alloy steels and structural metals

Advantages

- Bidirectional Threading – Mill both RH and LH threads with a single tool

- Full-Form Accuracy – Reduces need for secondary finishing or passes

- High-Speed Operation – Shorter cycle time compared to tapping

- Universal Use – Switch easily between internal and external threads

- Long Tool Life – Handles tough steels with excellent wear resistance

Usage Recommendations

- Use G76/G02/G03 cycles for helical interpolation in CNC machines

- Apply high-pressure coolant or MQL when machining stainless or P20

- Select coating based on workpiece material for optimal heat management

- Always verify clearance depth for full-profile tools in blind holes

- Adjust feeds and speeds based on thread pitch and material hardness

Get in Touch

We will provide you with feedback within 24 hours.