Metric Solid Carbide Forming Tap

- Technology: “Chipless” cold forming technology rearranges the metal structure instead of cutting it.

- Thread Strength: Creates threads with 100% higher pull-out strength due to compressed grain flow.

- Cleanliness: Zero chip generation—perfect for blind holes and critical electronic components.

- Material: Premium Solid Carbide offers superior wear resistance against the high friction of cold forming.

- Requirement: Requires larger drill sizes than standard cutting taps

Metric Solid Carbide Forming Taps (Roll Taps / Fluteless Taps)

For manufacturers working with ductile materials like Aluminum, Copper, or Stainless Steel, Metric Solid Carbide Forming Taps (also known as Roll Taps or Fluteless Taps) represent the ultimate upgrade in thread quality and process stability.

Unlike traditional taps that cut and remove material, Minnexon Forming Taps use the principle of Plastic Deformation. The tool’s polygon geometry displaces the material, flowing it into the thread shape like molding clay.

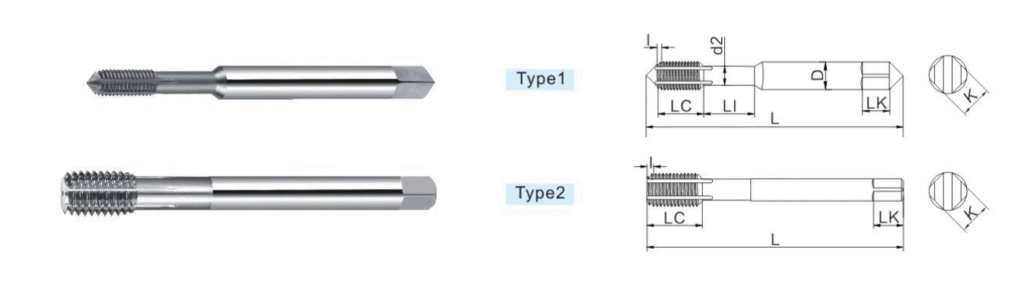

Technical Specifications (Customizable)

| Thread Size | I | L | D | LC | T | Z | KL | K | L1 | d2 |

|---|---|---|---|---|---|---|---|---|---|---|

| M1.0*0.25 | 1P | 42 | 3 | 5 | 4 | 5 | 2.5 | |||

| M1.2*0.25 | 1P | 42 | 3 | 5.5 | 4 | 5 | 2.5 | |||

| M1.4*0.3 | 1P | 42 | 3 | 6 | 4 | 5 | 2.5 | |||

| M1.6*0.35 | 1P | 42 | 3 | 8 | 4 | 5 | 2.5 | |||

| M1.7*0.35 | 1P | 42 | 3 | 8 | 4 | 5 | 2.5 | |||

| M1.8*0.35 | 1P | 42 | 3 | 9 | 4 | 5 | 2.5 | |||

| M2.0*0.4 | 1.5P | 42 | 3 | 10 | 4 | 5 | 2.5 | |||

| M2.5*0.45 | 1.5P | 42 | 3 | 11 | 4 | 5 | 2.5 | |||

| M3.0*0.5 | 1.5P | 52 | 4 | 11 | 4 | 6 | 3.2 | 6 | 2.4 | |

| M3.5*0.6 | 1.5P | 52 | 4 | 12 | 4 | 6 | 3.2 | 7 | 2.8 | |

| M4.0*0.7 | 1.5P | 55 | 5 | 12 | 4 | 2 | 7 | 4 | 7 | 3.1 |

| M5.0*0.8 | 1.5P | 60 | 5 | 15 | 4 | 2 | 7 | 4 | 10 | 4 |

| M6.0*1 | 1.5P | 65 | 6 | 16 | 4 | 4 | 7 | 4.5 | 10 | 4.8 |

| M8.0*1 | 1.5P | 73 | 6.2 | 18 | 6 | 6 | 8 | 5 | ||

| M8.0*1.25 | 1.5P | 73 | 6.2 | 18 | 6 | 6 | 8 | 5 | ||

| M10*1 | 2P | 75 | 8 | 21 | 6 | 6 | 9 | 6 | ||

| M10*1.25 | 2P | 75 | 8 | 21 | 6 | 6 | 9 | 6 | ||

| M10*1.5 | 2P | 75 | 8 | 21 | 6 | 6 | 9 | 6 | ||

| M12*1.0 | 2P | 83 | 9 | 22 | 6 | 6 | 9 | 7 | ||

| M12*1.25 | 2P | 83 | 9 | 25 | 6 | 6 | 9 | 7 | ||

| M12*1.5 | 2P | 83 | 9 | 25 | 8 | 8 | 9 | 7 | ||

| M12*1.75 | 2P | 83 | 9 | 25 | 8 | 8 | 9 | 7 | ||

| M14*1.5 | 2P | 90 | 10.5 | 26 | 8 | 8 | 11 | 8 | ||

| M14*2 | 2P | 90 | 10.5 | 26 | 8 | 8 | 11 | 8 | ||

| M16*1.5 | 2P | 98 | 12.5 | 29 | 8 | 8 | 13 | 10 | ||

| M16*2 | 2P | 98 | 12.5 | 29 | 8 | 8 | 13 | 10 | ||

| M18*1.5 | 2P | 100 | 14 | 33 | 8 | 8 | 14 | 11 | ||

| M18*2.5 | 2P | 100 | 14 | 33 | 8 | 8 | 14 | 11 |

Why Switch to Forming Taps? (The “Chipless” Advantage)

The biggest problem in threading is chips. Chips clog holes, break taps, and require cleaning. Minnexon Forming Taps eliminate this problem entirely.

- Zero Chips: Ideal for blind holes. No need to worry about chip evacuation or “bird-nesting.”

- Super-Strong Threads: By compressing the material grain structure (rather than severing it), the resulting thread is significantly stronger and harder. This is critical for aerospace and automotive fasteners.

- High Speed: Because there are no cutting edges to chip or dull, you can run these taps at higher surface speeds.

Critical Comparison: Forming Tap vs. Cutting Tap

Why would you choose one over the other? It comes down to Material Hardness and Thread Strength.

| Feature | Forming Tap (Roll Tap) | Cutting Tap (Straight/Spiral) |

| Process | Displacement (Cold Forming) | Shearing (Cutting) |

| Chips | NONE (Chipless) | Yes (Must be removed) |

| Thread Strength | High (Unbroken Grain Flow) | Standard (Cut Grain Flow) |

| Drill Size | Larger | Standard |

| Torque Load | Higher (Requires rigid machine) | Lower |

(Note: Forming taps are NOT suitable for brittle materials like Grey Cast Iron or Hardened Steel. For those, use our Solid Carbide Straight Flute Taps.)

The Minnexon Difference: Carbide vs. HSS Roll Taps

Cold forming generates intense heat and friction.

- HSS Forming Taps: Often wear out quickly because the high friction softens the steel substrate, leading to thread gauging errors.

- Solid Carbide: Tungsten Carbide maintains its hardness even under extreme heat. Combined with our advanced TiCN or TiAlN lubricious coatings, our taps reduce friction, prevent cold-welding (galling), and last 10x longer than HSS equivalents in mass production.

Get in Touch

We will provide you with feedback within 24 hours.