Metric Single-Form Thread Mill | Solid Carbide Thread Milling Cutter

- Selected solid carbide tungsten steel material, produced using German Walter equipment.

- Multiple coating options available, including uncoated, AlTiN, TiAlN, and DLC coatings.

- Suitable for machining 60° metric and imperial threads, compatible with various thread pitches and tapered threads.

- Applicable for both left-hand and right-hand threads, as well as internal and external threads.

Product Overview

The Metric Solid Carbide Single-Point Thread Mill is a high-precision cutting tool designed for thread milling in steel and other tough materials. Crafted from ultra-fine grain tungsten carbide, this tool offers superior hardness, heat resistance, and durability, making it ideal for threading 45# steel, stainless steel, P20 tool steel, and gray cast iron.

With its single-flute (single-point) design, this thread mill provides maximum control, reduced tool pressure, and the ability to produce internal or external threads with excellent surface finish. It is widely used in aerospace, automotive, mold making, and general machining, especially when thread accuracy and tool life are critical.

Key Features

Thread Type: Metric

Material: Premium solid tungsten carbide for extreme wear resistance

Design: Single-flute (single-point) for low cutting force and precision threading

Versatile Threading: Capable of internal and external thread milling

High Accuracy: Suitable for tight-tolerance, high-finish requirements

Applications

hread milling in medium to hard steels, including:

45# carbon steel

304 / 316 stainless steel

P20 mold steel

gray cast iron

Commonly used for:

Mold components

Machinery parts

Threaded holes in die casting or CNC milled parts

Compatible with CNC machining centers, tapping centers, and milling machines

Advantages

High-Precision Thread Profiles – Excellent pitch accuracy and finish

Low Cutting Pressure – Ideal for thin-walled or heat-sensitive parts

Flexible Threading – Use one tool for multiple thread diameters (via helical interpolation)

Improved Tool Life – Withstands high temperatures and tough materials

No Chip Jamming – Open single-flute design promotes clean evacuation

Usage Recommendations

Always match the thread profile to the proper G-code or thread milling cycle

Use appropriate coolant or MQL for stainless and heat-resistant materials

Adjust spindle speed and feed based on material hardness and thread pitch

Use climb milling for better surface finish in hardened steels

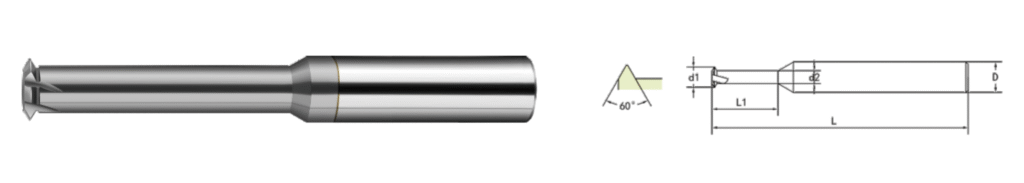

Technical Specifications (Customizable)

| M coarse | M fine | Pitch (mm) | d1 (mm) | L1 (mm) | D (mm) | L (mm) | F | Drill dia. (mm) |

|---|---|---|---|---|---|---|---|---|

| M0.6 * 0.15 | 0.15 | 0.43 | 1.2 | 4 | 50 | 3 | 0.45 | |

| M0.8 * 0.2 | 0.2 | 0.55 | 2 | 4 | 50 | 3 | 0.6 | |

| M0.9 * 0.225 | 0.225 | 0.6 | 2 | 4 | 50 | 3 | 0.675 | |

| M1 * 0.25 | 0.25 | 0.73 | 2.3 | 4 | 50 | 3 | 0.75 | |

| M1.2 * 0.25 | 0.25 | 0.92 | 2.8 | 4 | 50 | 3 | 0.95 | |

| M1.4 * 0.3 | 0.3 | 1.05 | 3.2 | 4 | 50 | 3 | 1.1 | |

| M1.6 * 0.35 | 0.35 | 1.21 | 3.5 | 4 | 50 | 3 | 1.25 | |

| M2 * 0.4 | 0.4 | 1.54 | 4.5 | 4 | 50 | 3 | 1.6 | |

| M2.5 * 0.45 | 0.45 | 1.96 | 5.5 | 4 | 50 | 3 | 2.05 | |

| M3 * 0.5 | 0.5 | 2.4 | 7 | 4 | 50 | 3 | 2.5 | |

| M4 * 0.7 | 0.7 | 3.15 | 10 | 4 | 50 | 4 | 3.3 | |

| M5 * 0.8 | 0.8 | 4 | 12 | 4 | 50 | 4 | 4.2 | |

| M5 * 0.8 | 0.8 | 4 | 13 | 6 | 50 | 4 | 4.2 | |

| M6 * 0.5 | 0.5 | 5 | 16 | 6 | 50 | 4 | 5.5 | |

| M6 * 0.75 | 0.75 | 5 | 16 | 6 | 50 | 4 | 5.25 | |

| M6 * 1.0 | 1 | 4.75 | 15 | 6 | 50 | 4 | 5 | |

| M8 * 0.5 | 0.5 | 6 | 16 | 6 | 50 | 4 | 7.5 | |

| M8 * 0.75 | 0.75 | 6 | 16 | 6 | 50 | 4 | 7.25 | |

| M8 * 1.0 | 1 | 6 | 16 | 6 | 50 | 4 | 7 | |

| M8 * 1.25 | 1.25 | 5.95 | 20 | 6 | 60 | 4 | 6.75 | |

| M10 * 0.5 | 0.5 | 8 | 25 | 8 | 60 | 4 | 9.5 | |

| M10 * 0.75 | 0.75 | 8 | 25 | 8 | 60 | 4 | 9.25 | |

| M10 * 1.0 | 1 | 8 | 25 | 8 | 60 | 4 | 9 | |

| M10 * 1.25 | 1.25 | 8 | 25 | 8 | 60 | 4 | 8.75 | |

| M10 * 1.5 | 1.5 | 7.9 | 25 | 8 | 60 | 6 | 8.5 | |

| M12 * 0.5 | 0.5 | 10 | 30 | 10 | 75 | 5 | 11.5 | |

| M12 * 0.75 | 0.75 | 10 | 30 | 10 | 75 | 5 | 11.25 | |

| M12 * 1.0 | 1 | 10 | 30 | 10 | 75 | 5 | 11 | |

| M12 * 1.25 | 1.25 | 10 | 30 | 10 | 75 | 5 | 10.75 | |

| M12 * 1.5 | 1.5 | 10 | 30 | 10 | 75 | 5 | 10.5 | |

| M12 * 1.75 | 1.75 | 9.9 | 30 | 10 | 75 | 6 | 10.25 | |

| M14 * 1.0 | 1 | 12 | 35 | 12 | 75 | 5 | 13 | |

| M14 * 1.5 | 1.5 | 12 | 35 | 12 | 75 | 5 | 12.5 | |

| M14 * 2.0 | 2 | 11.8 | 35 | 12 | 75 | 6 | 12 | |

| M16 * 1.0 | 1 | 14 | 40 | 16 | 75 | 5 | 15 | |

| M16 * 1.5 | 1.5 | 14 | 40 | 16 | 75 | 5 | 14.5 | |

| M16 * 2.0 | 2 | 13.8 | 40 | 16 | 75 | 6 | 14 | |

| M18 * 1.0 | 1 | 16 | 45 | 16 | 75 | 5 | 17 | |

| M18 * 1.5 | 1.5 | 16 | 45 | 16 | 75 | 5 | 16.5 | |

| M18 * 2.5 | 2.5 | 15.3 | 45 | 16 | 75 | 6 | 15.5 | |

| M20 * 1.0 | 1 | 18 | 50 | 20 | 90 | 5 | 19 | |

| M20 * 1.5 | 1.5 | 18 | 50 | 20 | 90 | 5 | 18.5 | |

| M20 * 2.5 | 2.5 | 17.3 | 50 | 20 | 90 | 6 | 17.5 | |

| M22 * 1.0 | 1 | 20 | 55 | 20 | 90 | 5 | 21 | |

| M22 * 1.5 | 1.5 | 20 | 55 | 20 | 90 | 5 | 20.5 | |

| M22 * 2.5 | 2.5 | 19.3 | 55 | 20 | 90 | 6 | 19.5 | |

| M24 * 1.0 | 1 | 22 | 60 | 24 | 90 | 5 | 23 | |

| M24 * 1.5 | 1.5 | 22 | 60 | 24 | 90 | 5 | 22.5 | |

| M24 * 3.0 | 3 | 20.7 | 60 | 24 | 90 | 6 | 21 | |

| M27 * 1.0 | 1 | 25 | 65 | 24 | 90 | 5 | 26 | |

| M27 * 1.5 | 1.5 | 25 | 65 | 24 | 90 | 5 | 25.5 | |

| M27 * 3.0 | 3 | 23.7 | 65 | 24 | 90 | 6 | 24 | |

| M30 * 1.0 | 1 | 28 | 70 | 24 | 90 | 5 | 29 | |

| M30 * 1.5 | 1.5 | 28 | 70 | 24 | 90 | 5 | 28.5 | |

| M30 * 3.5 | 3.5 | 26.2 | 70 | 24 | 90 | 6 | 26.5 | |

| M33 * 1.5 | 1.5 | 31 | 80 | 32 | 110 | 5 | 31.5 | |

| M33 * 3.5 | 3.5 | 29.2 | 80 | 32 | 110 | 6 | 29.5 | |

| M36 * 1.5 | 1.5 | 34 | 85 | 32 | 110 | 5 | 34.5 | |

| M36 * 4.0 | 4 | 31.7 | 85 | 32 | 110 | 6 | 32 |

Related products

Get in Touch

We will provide you with feedback within 24 hours.