Metric Solid Carbide Spiral Flute Tap

- Core Function: High-helix geometry specifically designed to pull chips out of blind holes.

- Material: Premium Solid Carbide offers superior rigidity compared to HSS, preventing tool deflection in deep holes.

- Geometry: 15-35° Spiral Flute for efficient evacuation of long, stringy chips.

- Application: Ideal for Stainless Steel, Carbon Steel, and Aluminum where chip clogging is a risk.

- Precision: Precision ground to ISO metric tolerances for aerospace and automotive standards.

Metric Solid Carbide Spiral Flute Taps

Threading blind holes (holes that do not go all the way through) presents the biggest challenge in machining: Chip Evacuation. If chips accumulate at the bottom of the hole, the tap will bind and break. Minnexon Metric Solid Carbide Spiral Flute Taps solve this physics problem. Unlike standard taps that push chips forward or store them in grooves, our spiral flute geometry acts like an Archimedean screw. It actively pumps chips up and out of the hole, ensuring the cutting zone remains clear. This allows for continuous, high-speed threading without the risk of “bird-nesting” or jamming.

Technical Specifications (Customizable)

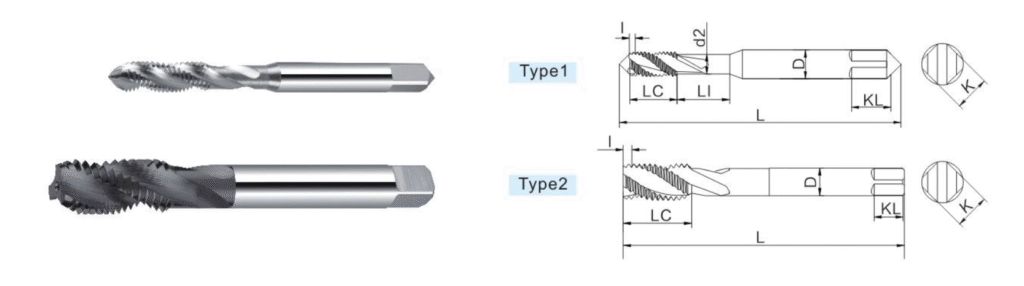

| Thread Size | I | L | LC | D | Flute | Angle | KL | K | L1 | d2 |

|---|---|---|---|---|---|---|---|---|---|---|

| M1.4 * 0.3 | 1.5P | 42 | 6 | 3 | 2 | 35 | 5 | 2.5 | ||

| M1.6 * 0.35 | 1.5P | 42 | 8 | 3 | 2 | 35 | 5 | 2.5 | ||

| M1.7 * 0.35 | 1.5P | 42 | 8 | 3 | 2 | 35 | 5 | 2.5 | ||

| M1.8 * 0.35 | 1.5P | 42 | 9 | 3 | 2 | 35 | 5 | 2.5 | ||

| M2.0 * 0.4 | 1.5P | 42 | 10 | 3 | 2 | 35 | 5 | 2.5 | ||

| M2.5 * 0.45 | 1.5P | 42 | 11 | 3 | 2 | 35 | 5 | 2.5 | ||

| M3.0 * 0.5 | 2P | 52 | 11 | 4 | 3 | 30 | 6 | 3.2 | 6 | 2.4 |

| M3.5 * 0.6 | 2P | 52 | 12 | 4 | 3 | 30 | 6 | 3.2 | 7 | 2.8 |

| M4.0 * 0.7 | 2P | 55 | 13 | 5 | 3 | 30 | 7 | 4 | 7 | 3.1 |

| M5.0 * 0.8 | 2P | 60 | 15 | 5 | 3 | 30 | 7 | 4 | 10 | 4 |

| M6.0 * 1 | 2.5P | 65 | 16 | 6 | 3 | 30 | 7 | 4.5 | 10 | 4.8 |

| M8.0 * 1 | 2.5P | 73 | 18 | 6.2 | 3 | 30 | 8 | 5 | ||

| M8.0 * 1.25 | 2.5P | 73 | 18 | 6.2 | 3 | 30 | 8 | 5 | ||

| M10 * 1 | 2.5P | 75 | 21 | 8 | 3 | 30 | 9 | 6 | ||

| M10 * 1.25 | 2.5P | 75 | 21 | 8 | 3 | 30 | 9 | 6 | ||

| M10 * 1.5 | 2.5P | 75 | 21 | 8 | 3 | 30 | 9 | 6 | ||

| M12 * 1.0 | 2.5P | 83 | 25 | 9 | 4 | 15 | 9 | 7 | ||

| M12 * 1.25 | 2.5P | 83 | 25 | 9 | 4 | 15 | 9 | 7 | ||

| M12 * 1.5 | 2.5P | 83 | 25 | 9 | 4 | 15 | 9 | 7 | ||

| M12 * 1.75 | 2.5P | 83 | 25 | 9 | 4 | 15 | 9 | 7 | ||

| M14 * 1.5 | 2.5P | 90 | 26 | 10.5 | 4 | 15 | 11 | 8 | ||

| M14 * 2 | 2.5P | 90 | 26 | 10.5 | 4 | 15 | 11 | 8 | ||

| M16 * 1.5 | 2.5P | 98 | 29 | 12.5 | 4 | 15 | 13 | 10 | ||

| M16 * 2 | 2.5P | 98 | 29 | 12.5 | 4 | 15 | 13 | 10 | ||

| M18 * 1.5 | 2.5P | 100 | 33 | 14 | 4 | 15 | 14 | 11 |

Why Solid Carbide Matters for Spiral Taps?

While spiral flute geometry is excellent for chip removal, the deep flutes can structurally weaken the core of the tool. This is where Minnexon’s Solid Carbide material changes the game.

Most competitors offer High-Speed Steel (HSS) spiral taps. HSS is flexible but prone to twisting under high torque.

The Minnexon Advantage: By manufacturing these taps from Micro-grain Tungsten Carbide, we compensate for the geometric stress. Our taps provide the stiffness required to maintain thread pitch accuracy while delivering the hardness to machine tough alloys like Stainless Steel 316 or Titanium.

Technical Comparison: Spiral Flute vs. Straight Flute

Choosing the right tap depends entirely on your hole type and material.

| Feature | Spiral Flute Tap (This Product) | Straight Flute Tap |

| Hole Type | Blind Holes (Non-through) | Through Holes / Shallow Blind Holes |

| Chip Flow | Upwards (Back out of hole) | Stays in groove |

| Best Material | Long-chipping / Ductile (Stainless, Aluminum, Steel) | Short-chipping / Brittle (Cast Iron, Brass) |

| Core Strength | Moderate (Reinforced by Carbide) | High |

Rule of Thumb: If the hole has a bottom and the material makes long, curly chips, you must use a Spiral Flute Tap.

Target Materials & Applications

Our Carbide Spiral Flute Taps are engineered for materials that are “sticky” or ductile—materials that would otherwise clog a straight flute tap.

- Stainless Steels: 300 Series (304, 316) and 400 Series.

- Carbon & Alloy Steels: Low to medium carbon steels where chips are continuous.

- Aluminum Alloys: Wrought aluminum (6061, 7075) where long ribbons are formed.

- Titanium Alloys: (Recommended with specific coolant strategies).

Note: For Cast Iron or short-chipping brass, please switch to our Metric Solid Carbide Straight Flute Taps for better tool life.

Get in Touch

We will provide you with feedback within 24 hours.