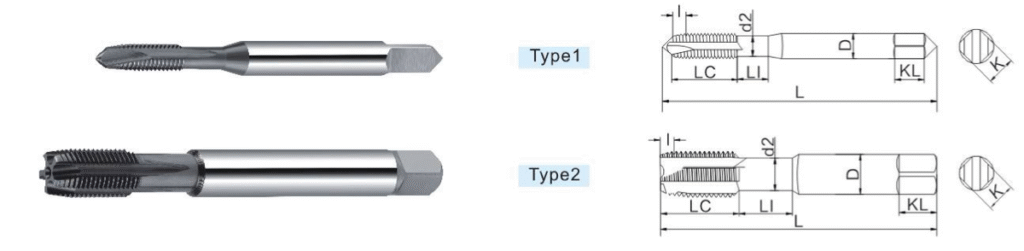

Metric Solid Carbide Spiral Point Tap

- Chip Control: “Gun Tap” geometry pushes chips forward (down), preventing clogging in through holes.

- Productivity: The strongest tap design allows for the highest cutting speeds among all tap types.

- Material: Solid Carbide substrate offers 3x rigidity of HSS, ensuring precise thread gauging.

- Application: Exclusively for Through Holes (open bottom) in Steels, Stainless, and Aluminum.

- Durability: Thick core design reduces breakage risk significantly compared to spiral flute taps.

The Speed King of Threading: Why Use Spiral Point?

If you are threading holes that go all the way through the workpiece (Through Holes), the Metric Solid Carbide Spiral Point Tap is your absolute best choice for speed and reliability.

Often called a “Gun Tap,” this tool features a specialized angular grind at the tip. Instead of pulling chips up or storing them in the flutes, it shoots the chips forward ahead of the tap.

The “Forward Chip” Advantage:

- No Clogging: Since chips are pushed out the bottom, they never interfere with the cutting teeth.

- Stronger Tool: Because the flutes don’t need to hold chips, they can be shallower. This leaves a thicker, stronger core compared to spiral flute taps, allowing for higher torque and faster RPMs.

- Coolant Access: The shallow flutes allow coolant to flow freely to the cutting edge, extending tool life.

Technical Specifications (Customizable)

| Thread Size | I | L | LC | D | Flute | KL | K | L1 | d2 |

|---|---|---|---|---|---|---|---|---|---|

| M2.0×0.4 | 5P | 42 | 10 | 3 | 2 | 5 | 2.5 | ||

| M2.5×0.45 | 5P | 42 | 11 | 3 | 2 | 5 | 2.5 | ||

| M3.0×0.5 | 5P | 52 | 11 | 4 | 3 | 6 | 3.2 | 6 | 2.4 |

| M3.5×0.6 | 5P | 52 | 12 | 4 | 3 | 6 | 3.2 | 7 | 2.8 |

| M4.0×0.7 | 5P | 55 | 13 | 5 | 3 | 7 | 4 | 7 | 3.1 |

| M5.0×0.8 | 5P | 60 | 15 | 5 | 3 | 7 | 4 | 10 | 4 |

| M6.0×1 | 5P | 65 | 16 | 6 | 3 | 7 | 4.5 | 10 | 4.8 |

| M8.0×1 | 5P | 73 | 18 | 6.2 | 3 | 8 | 5 | ||

| M8.0×1.25 | 5P | 73 | 18 | 6.2 | 3 | 8 | 5 | ||

| M10×1 | 5P | 75 | 21 | 8 | 4 | 9 | 6 | ||

| M10×1.25 | 5P | 75 | 21 | 8 | 4 | 9 | 6 | ||

| M10×1.5 | 5P | 75 | 21 | 8 | 4 | 9 | 6 | ||

| M12×1.0 | 5P | 83 | 25 | 9 | 4 | 9 | 7 | ||

| M12×1.25 | 5P | 83 | 25 | 9 | 4 | 9 | 7 | ||

| M12×1.5 | 5P | 83 | 25 | 9 | 4 | 9 | 7 | ||

| M12×1.75 | 5P | 83 | 25 | 9 | 4 | 9 | 7 | ||

| M14×1.5 | 5P | 90 | 26 | 10.5 | 4 | 11 | 8 | ||

| M14×2 | 5P | 90 | 26 | 10.5 | 4 | 11 | 8 | ||

| M16×1.5 | 5P | 98 | 29 | 12.5 | 4 | 13 | 10 | ||

| M16×2 | 5P | 98 | 29 | 12.5 | 4 | 13 | 10 | ||

| M18×1.5 | 5P | 100 | 33 | 14 | 4 | 14 | 11 | ||

| M18×2.5 | 5P | 100 | 33 | 14 | 4 | 14 | 11 | ||

| M20×1.5 | 5P | 105 | 33 | 15 | 4 | 15 | 12 | ||

| M20×2.5 | 5P | 105 | 33 | 15 | 4 | 15 | 12 |

Critical Question: Spiral Point vs. Straight Flute?

Many customers ask: “This looks like a straight flute tap. What is the difference?” While they look similar, their mechanics are opposite.

| Feature | Spiral Point (This Product) | Straight Flute Tap |

| Chip Direction | Forward (Down) | Stays in Flute |

| Best For | Through Holes Only | Short Blind or Through Holes |

| Chip Type | Long, stringy chips (Steel/Aluminum) | Powder/Short chips (Cast Iron) |

| Speed | High Speed | Medium/Low Speed |

Why it matters: If you use a Straight Flute tap on Ductile Steel, the long chips will clog the grooves and break the tap. A Spiral Point tap pushes those long chips out of the way, making it the superior choice for mass production in steels.

Why Minnexon Solid Carbide?

Standard HSS Gun Taps are flexible. While this can be forgiving, it limits performance. Minnexon upgrades this classic design with Micro-grain Solid Carbide.

- Rigidity: No flexing means threads are cut exactly to gauge, not oversized.

- Heat Resistance: Run dry or with minimal coolant at speeds HSS cannot touch.

- Wear Life: Perfect for abrasive setups or high-volume automated production lines where tool change downtime is costly.

Ideal Materials

Because of the robust “forward push” action, these taps are highly versatile for long-chipping materials:

- Carbon Steels & Alloy Steels

- Stainless Steel (304, 316)

- Wrought Aluminum & Copper Alloys

- Titanium Alloys (Through holes only)

Warning: Do not use Spiral Point Taps for Blind Holes! The chips will hit the bottom, pack tight, and break the tap instantly. For blind holes, use our Spiral Flute Taps.

Difficult-to-Machine Materials?

If you are working with hardened steel (HRC 45+) or require absolute thread safety without the risk of tap breakage, consider our Solid Carbide Thread Milling Cutters. Thread mills offer the highest process security for high-value components.

Get in Touch

We will provide you with feedback within 24 hours.