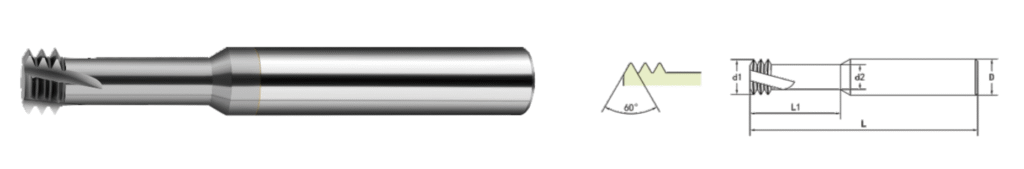

Metric Tri-Form Thread Mill | Solid Carbide Thread Milling Cutter

- Selected solid carbide tungsten steel material, produced using German Walter equipment.

- Multiple coating options available, including uncoated, AlTiN, TiAlN, and DLC coatings.

- Ultra-strong cutting edge design reduces the risk of breakage inside holes, provides chipping resistance, and ensures long tool life.

- Applicable for both left-hand and right-hand threads, as well as internal and external threads.

Product Overview

The Metric Solid Carbide Triple-Flute Thread Mill is a robust, high-efficiency threading solution engineered for cutting internal and external threads in difficult-to-machine materials. Designed specifically for steel applications, this tool performs exceptionally well on 45# carbon steel, stainless steel (304/316), P20 mold steel, and cast iron, delivering both speed and precision.

Constructed from premium tungsten carbide, this thread mill features a three-flute cutting geometry that provides balanced cutting forces, superior chip evacuation, and higher feed rates compared to single-flute tools. It’s ideal for production threading, precision molds, and high-strength components, where consistency and tool life are critical.

Key Features

Thread Standard: Metric threads (M-series)

Material: Ultra-hard solid tungsten carbide for maximum durability

Flute Design: Triple-flute geometry for enhanced cutting speed and tool stability

Thread Types: Internal & external threads via helical interpolation

Excellent Chip Control: Suitable for long, blind, and deep-hole threading

Applications

hread milling in medium to hard steels, including:

45# medium carbon steel

304 & 316 stainless steels

P20 pre-hardened mold steel

Gray cast iron and ductile iron

Other alloyed and structural steels

Commonly used for:

Mold components

Machinery parts

Threaded holes in die casting or CNC milled parts

Compatible with CNC machining centers, tapping centers, and milling machines

Advantages

High-speed threading with excellent dimensional consistency

Clean thread finishes even in tough or abrasive steels

Strong and stable tool body resists deflection in high-feed operations

Reduced cycle time compared to single-flute alternatives

Ideal for mass production and precision applications alike

Usage Recommendations

Use helical interpolation G-code for thread paths (G02/G03)

Apply proper coolant or mist lubrication for longer tool life

Match RPM and feed rate to material type and thread pitch

For blind holes, ensure proper clearance for tool overrun

Technical Specifications (Customizable)

| M coarse | M fine | P (mm) | d1 (mm) | L1 (mm) | D (mm) | L (mm) | F (mm) | Drill dia. (mm) |

|---|---|---|---|---|---|---|---|---|

| M1×0.25 | 0.25 | 0.73 | 2.3 | 4 | 50 | 3 | 0.75 | |

| M1.2×0.25 | 0.25 | 0.92 | 3.3 | 4 | 50 | 3 | 0.95 | |

| M1.4×0.3 | 0.3 | 1.05 | 3.2 | 4 | 50 | 3 | 1.1 | |

| M1.6×0.35 | 0.35 | 1.21 | 3.5 | 4 | 50 | 3 | 1.25 | |

| M1.7×0.35 | 0.35 | 1.3 | 4.3 | 4 | 50 | 3 | 1.35 | |

| M1.8×0.35 | 0.35 | 1.4 | 4 | 4 | 50 | 3 | 1.45 | |

| M2×0.4 | 0.4 | 1.54 | 4.5 | 4 | 50 | 3 | 1.6 | |

| M2.2×0.45 | 0.45 | 1.65 | 5 | 4 | 50 | 3 | 1.75 | |

| M2.5×0.45 | 0.45 | 1.96 | 5.5 | 4 | 50 | 3 | 2.05 | |

| M2.5×0.35 | 0.35 | 1.96 | 7.5 | 4 | 50 | 3 | 2.15 | |

| M3×0.5 | 0.5 | 2.42 | 7 | 4 | 50 | 3 | 2.5 | |

| M3.5×0.6 | 0.6 | 2.75 | 9 | 4 | 50 | 3 | 2.9 | |

| M3.5×0.35 | 0.35 | 3 | 5 | 4 | 50 | 3 | 3.15 | |

| M3×0.35 | 0.35 | 2.5 | 6 | 4 | 50 | 3 | 2.65 | |

| M4×0.5 | 0.5 | 3.4 | 8 | 4 | 50 | 3 | 3.5 | |

| M4.5×0.75 | 0.75 | 3.5 | 11 | 4 | 50 | 3 | 3.75 | |

| M4×0.7 | 0.7 | 3.15 | 10 | 4 | 50 | 3 | 3.3 | |

| M4×0.35 | 0.35 | 3.3 | 6 | 4 | 50 | 3 | 3.65 | |

| M5×0.5 | 0.5 | 3.9 | 8 | 4 | 50 | 3 | 4.5 | |

| M5×0.75 | 0.75 | 3.9 | 8 | 4 | 50 | 3 | 4.25 | |

| M5×0.8 | 0.8 | 4 | 12 | 6 | 50 | 3 | 4.2 | |

| M5×0.8 | 0.8 | 3.95 | 12 | 4 | 50 | 3 | 4.2 | |

| M6×0.5 | 0.5 | 4.8 | 13 | 6 | 50 | 3 | 5.5 | |

| M6×0.75 | 0.75 | 5 | 13 | 6 | 50 | 3 | 5.25 | |

| M6×1.0 | 1 | 3.95 | 14 | 4 | 50 | 3 | 5 | |

| M6×1.0 | 1 | 4.75 | 13 | 6 | 50 | 3 | 5 | |

| M8×0.5 | 0.5 | 5.95 | 16 | 6 | 50 | 4 | 7.5 | |

| M8×0.75 | 0.75 | 5.95 | 20 | 6 | 50 | 3 | 7.25 | |

| M8×1.0 | 1 | 5.9 | 20 | 6 | 60 | 3 | 7 | |

| M8×1.25 | 1.25 | 5.95 | 17.5 | 6 | 50 | 3 | 6.75 | |

| M10×0.5 | 0.5 | 7.95 | 25 | 8 | 60 | 4 | 9.5 | |

| M10×0.75 | 0.75 | 7.95 | 25 | 8 | 60 | 4 | 9.25 | |

| M10×1.0 | 1 | 7.9 | 21 | 8 | 60 | 4 | 9 | |

| M10×1.25 | 1.25 | 7.95 | 21 | 8 | 60 | 4 | 8.75 | |

| M10×1.5 | 1.5 | 7.9 | 22 | 8 | 60 | 4 | 8.5 | |

| M12×1.0 | 1 | 9.9 | 30 | 10 | 75 | 4 | 11 | |

| M12×1.5 | 1.5 | 9.9 | 30 | 10 | 75 | 4 | 10.5 | |

| M12×1.25 | 1.25 | 9.9 | 30 | 10 | 75 | 4 | 10.75 | |

| M12×1.75 | 1.75 | 9.9 | 28 | 10 | 75 | 4 | 10.25 | |

| M14×2.0 | 2 | 9.9 | 28 | 10 | 75 | 4 | 12 | |

| M16×1.5 | 1.5 | 11.9 | 35 | 12 | 75 | 4 | 14.5 | |

| M16×2.0 | 2 | 11.9 | 35 | 12 | 75 | 4 | 14 | |

| M18×2.5 | 2.5 | 13.9 | 40 | 14 | 83 | 5 | 15.5 | |

| M20×2.5 | 2.5 | 15.9 | 50 | 16 | 100 | 6 | 17.5 | |

| M24×3.0 | 3 | 15.9 | 50 | 16 | 100 | 6 | 21 | |

| M30×3.5 | 3.5 | 15.9 | 50 | 16 | 100 | 6 | 26.5 |

Get in Touch

We will provide you with feedback within 24 hours.