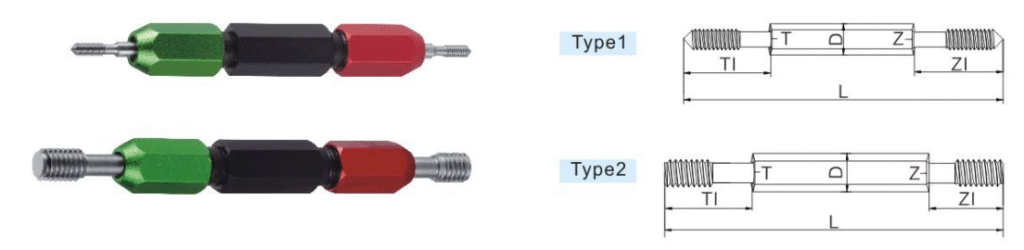

Metric Tungsten Carbide Thread Plug Gauge | High Precision 6H Go/No-Go Gage

- Solid Tungsten Carbide Material – 10x longer life than steel.

- ISO Metric 6H Precision – High accuracy Go/No-Go gauges.

- Custom & Standard Sizes – From M1.4 to M18.

Maximize Your Inspection Efficiency

Introducing our premium Metric Carbide Thread Plug Gauges. These tools are the best solution for high-volume production lines and precision quality control. We design them for manufacturers who need extreme accuracy and long tool life.

Standard Specifications (ISO Metric)

| Thread Size | Tl | Zl | L | D |

|---|---|---|---|---|

| M1.4 * 0.3 | 6 | 5 | 78 | 9 |

| M1.6 * 0.35 | 6 | 5 | 78 | 9 |

| M1.7 * 0.35 | 6 | 5 | 78 | 9 |

| M1.8 * 0.35 | 7 | 6 | 78 | 9 |

| M2.0 * 0.4 | 7 | 6 | 78 | 9 |

| M2.5 * 0.45 | 9 | 8 | 82 | 9 |

| M3.0 * 0.5 | 10 | 8 | 82 | 9 |

| M3.5 * 0.6 | 10 | 8 | 82 | 9 |

| M4.0 * 0.7 | 10 | 8 | 88 | 9 |

| M5.0 * 0.8 | 13 | 11 | 90 | 9 |

| M6.0 * 1 | 18 | 12 | 90 | 9 |

| M8.0 * 1 | 20 | 15 | 120 | 12 |

| M8.0 * 1.25 | 20 | 15 | 120 | 12 |

| M10 * 1 | 21 | 15 | 120 | 12 |

| M10 * 1.25 | 21 | 15 | 120 | 12 |

| M10 * 1.5 | 21 | 15 | 120 | 12 |

| M12 * 1.0 | 25 | 15 | 130 | 14 |

| M12 * 1.25 | 25 | 15 | 130 | 14 |

| M12 * 1.5 | 25 | 15 | 130 | 14 |

| M12 * 1.75 | 25 | 15 | 130 | 14 |

| M14 * 1.5 | 27 | 17 | 135 | 14 |

| M14 * 2 | 27 | 17 | 135 | 14 |

| M16 * 1.5 | 30 | 20 | 140 | 14 |

| M16 * 2 | 30 | 20 | 140 | 14 |

| M18 * 1.5 | 30 | 20 | 140 | 14 |

| M18 * 2.5 | 30 | 20 | 140 | 14 |

Superior Material: Tungsten Carbide vs. Steel

The core advantage of our product is the material. We use high-grade solid tungsten carbide. This material is significantly different from common bearing steel or tool steel.

Standard steel gauges wear out quickly. This happens especially when checking abrasive materials. Our carbide thread gauges offer exceptional hardness. They provide wear resistance that is 10 to 50 times higher than steel gauges. This means you do not need to replace them frequently. It saves you money on replacement costs and calibration time.

High Precision and Stability

Accuracy is critical for thread inspection. Our gauges feature excellent dimensional stability. They maintain their accuracy over time and do not deform easily.

- Thread Angle: Standard 60-degree metric thread profile.

- Tolerance Class: Precision 6H limit (most common for internal threads).

- Function: Includes both Go and No-Go members to verify the thread size limits effectively.

Ideal Applications

These carbide thread gages are perfect for inspecting difficult materials. They perform excellently on cast iron, high-silicon aluminum, copper, and hard plastics. If you face fast wear issues with your current gauges, upgrading to carbide is the right choice.

Frequently Asked Questions (FAQs)

Q: Why choose tungsten carbide over steel gauges?

A: Tungsten carbide is much harder than steel. It offers superior wear resistance. A carbide thread plug gauge typically lasts 10 to 50 times longer than a steel gauge. This is very important for checking abrasive materials like cast iron or aluminum. It reduces the frequency of purchasing new gauges.

Q: What does the “6H” tolerance mean?

A: “6H” is the standard tolerance class for metric internal threads. It describes the fit between the screw and the nut. Our gauges follow the ISO standard 6H class. This ensures your threaded holes fit perfectly with standard bolts. We can also provide other classes like 4H or 6G upon request.

Q: Do you provide calibration certificates?

A: Yes. Quality is our priority. Every metric carbide thread gauge comes with a factory inspection report. This report proves that the tool meets the required dimensional standards. We ensure specific pitch diameter and major diameter accuracy before shipment.

Q: Can I order non-standard or special pitch gauges?

A: Yes. We are a professional manufacturer. We can produce special items according to your needs. If you need a fine pitch, a specific diameter, or a left-hand thread, please contact our team. We can provide a quick quote for custom carbide thread gauges.

Q: How should I store these gauges?

A: Carbide is hard but brittle. Please handle them with care. Do not drop them on hard floors. Clean the gauge after use and apply anti-rust oil. Store them in the provided plastic box or a wooden case to prevent damage.

Looking for Threading Tools?

Before inspecting your parts, ensure your production is efficient. Our [Carbide Thread Mills] and [Carbide Taps] are designed to work perfectly with our gauges. They help you produce accurate threads from the start, reducing scrap rates.

Get in Touch

We will provide you with feedback within 24 hours.