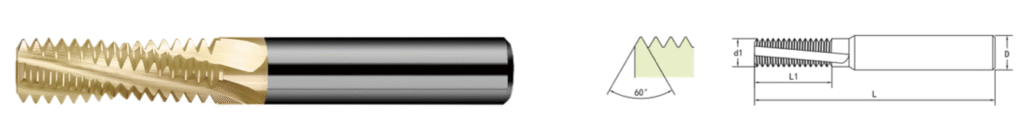

Multi-Form Thread Mills for Titanium, Nickel & Kovar

Master serial production in difficult alloys. Minnexon Multi-Form Thread Mills eliminate work hardening in Titanium and ensure consistent gauging in Kovar and Nickel alloys.

- Internal and External: Safely machine both internal and external threads.

- Left and Right Hand: You can create right-hand or left-hand threads simply by changing the CNC program.

The Challenge: Scaling Up Production in “Sticky” Metals

Prototyping in Titanium or Kovar is one thing; running thousands of parts is another. When you move from testing to serial production threading, standard tools often fail due to the unique properties of these materials:

- Titanium Work Hardening: Repeated passes with single-point tools generate heat, causing Titanium surfaces to harden instantly, destroying the tool’s edge.

- Galling in Nickel Alloys: The material welds itself to the cutter, leading to poor thread finish and thread gauging failures.

- Kovar Abrasiveness: Machining Kovar glass-to-metal seal components requires tools that can withstand high abrasion while cutting gummy material.

You need a tool that cuts cleanly, quickly, and stays cool. You need the Minnexon Multi-Form solution.

The Minnexon Solution: One-Pass Stability

Our Solid Carbide Multi-Form Thread Mills are engineered to solve the specific behaviors of these aerospace and electronic alloys.

1. Eliminate Work Hardening (The “One-Pass” Strategy)

The biggest enemy in machining Titanium Gr5 is heat buildup.

- How we solve it: Our multi-form design cuts the full thread depth along the entire axis simultaneously.

- The Benefit: By utilizing a single-pass helical interpolation, we minimize the contact time between the tool and the part. This prevents the material from hardening, ensuring a clean cut and dramatically extending tool life.

2. The “Golden Coating” for Kovar & Nickel

Kovar and Nickel-based alloys are notoriously “gummy” yet abrasive.

- Anti-Adhesion Barrier: Our strategic Golden Coating prevents the material from welding to the cutting flutes (built-up edge). This is critical for maintaining thread tolerance in Kovar.

- Thermal Shock Resistance: The coating protects the carbide substrate from the thermal shock of entering and exiting the cut, which is common in interrupted cutting of superalloys.

3. Rigid Design for Consistent Gauging

When machining thousands of connectors or implants, every thread must pass the Go/No-Go gauge.

- Reduced Deflection: Unlike single-point tools, our multi-form cutters have a larger core diameter. This rigidity eliminates the “tapered thread” issue often seen when thread milling deep holes in alloy steel.

Technical Specifications (Customizable)

| M coarse | M fine | Pitch | d1/mm | L1/mm | D/mm | L/mm | Flutes | Drill dia./mm |

|---|---|---|---|---|---|---|---|---|

| M1.6×0.35 | 0.35 | 1.2 | 3.5 | 4 | 50 | 3 | 1.25 | |

| M2×0.4 | 0.4 | 1.54 | 5 | 4 | 50 | 3 | 1.6 | |

| M2.5×0.45 | 0.45 | 1.96 | 6 | 4 | 50 | 3 | 2.05 | |

| M3×0.5 | 0.5 | 2.4 | 7.5 | 4 | 50 | 3 | 2.5 | |

| M3.5×0.6 | 0.6 | 2.75 | 8.5 | 4 | 50 | 3 | 2.9 | |

| M4×0.5 | 0.5 | 3 | 8 | 4 | 50 | 3 | 3.5 | |

| M4×0.7 | 0.7 | 3.15 | 10 | 4 | 50 | 3 | 3.3 | |

| M4.5×0.75 | 0.75 | 3.4 | 9 | 4 | 50 | 3 | 3.75 | |

| M5×0.5 | 0.5 | 3.9 | 12 | 4 | 50 | 3 | 4.5 | |

| M5×0.8 | 0.8 | 3.95 | 12 | 4 | 50 | 3 | 4.2 | |

| M5×0.8 | 0.8 | 3.9 | 13 | 6 | 50 | 3 | 4.2 | |

| M6×0.5 | 0.5 | 4.8 | 13 | 6 | 50 | 3 | 5.5 | |

| M6×0.75 | 0.75 | 3.9 | 12 | 4 | 50 | 3 | 5.25 | |

| M6×1.0 | 1 | 3.95 | 12 | 4 | 50 | 3 | 5 | |

| M6×1.0 | 1 | 4.75 | 13 | 6 | 50 | 3 | 5 | |

| M8×0.5 | 0.5 | 5.9 | 16 | 6 | 60 | 3 | 7.5 | |

| M8×0.75 | 0.75 | 5.95 | 18 | 6 | 60 | 3 | 7.25 | |

| M8×1.0 | 1 | 5.95 | 15 | 6 | 60 | 3 | 7 | |

| M8×1.25 | 1.25 | 5.9 | 18 | 6 | 60 | 3 | 6.75 | |

| M10×0.5 | 0.5 | 7.9 | 20 | 8 | 65 | 4 | 9.5 | |

| M10×0.75 | 0.75 | 7.9 | 22 | 8 | 65 | 4 | 9.25 | |

| M10×1.0 | 1 | 7.95 | 22 | 8 | 65 | 4 | 9 | |

| M10×1.25 | 1.25 | 7.9 | 20 | 8 | 65 | 4 | 8.75 | |

| M10×1.5 | 1.5 | 7.7 | 22 | 8 | 65 | 4 | 8.5 | |

| M12×0.5 | 0.5 | 9.95 | 25 | 10 | 75 | 4 | 11.5 | |

| M12×0.75 | 0.75 | 9.95 | 20 | 10 | 75 | 4 | 11.25 | |

| M12×1.0 | 1 | 9.9 | 28 | 10 | 75 | 4 | 11 | |

| M12×1.25 | 1.25 | 9.9 | 25 | 10 | 75 | 4 | 10.75 | |

| M12×1.5 | 1.5 | 9.4 | 24 | 10 | 75 | 4 | 10.5 | |

| M12×1.75 | 1.75 | 9.5 | 25 | 10 | 75 | 4 | 10.25 | |

| M14×0.5 | 0.5 | 11.9 | 30 | 12 | 75 | 4 | 13.5 | |

| M14×1.0 | 1 | 11.9 | 30 | 12 | 75 | 4 | 13 | |

| M14×1.5 | 1.5 | 9.9 | 25 | 10 | 75 | 4 | 12.5 | |

| M14×1.5 | 1.5 | 11.2 | 30 | 12 | 75 | 4 | 12.5 | |

| M14×2.0 | 2 | 9.9 | 30 | 10 | 75 | 4 | 12 | |

| M14×2.0 | 2 | 11.2 | 30 | 12 | 75 | 4 | 12 | |

| M16×1.5 | 1.5 | 12 | 30 | 12 | 75 | 4 | 14.5 | |

| M16×2.0 | 2 | 11.9 | 30 | 12 | 75 | 4 | 14 | |

| M18×2.0 | 2 | 13.9 | 33 | 14 | 100 | 4 | 16 | |

| M18×2.5 | 2.5 | 13.9 | 33 | 14 | 100 | 5 | 15.5 | |

| M20×1.5 | 1.5 | 15.95 | 40 | 16 | 100 | 5 | 18.5 | |

| M20×1.0 | 1 | 16 | 40 | 16 | 100 | 5 | 19 | |

| M20×2.0 | 2 | 15.95 | 40 | 16 | 100 | 5 | 18 | |

| M20×2.5 | 2.5 | 15.9 | 40 | 16 | 100 | 5 | 17.5 | |

| M24×3.0 | 3 | 15.9 | 40 | 16 | 100 | 5 | 21 | |

| M30×2.0 | 2 | 20 | 40 | 20 | 100 | 5 | 28 | |

| M30×3.5 | 3.5 | 15.9 | 40 | 16 | 100 | 5 | 26.5 | |

| M36×4.0 | 4 | 20 | 40 | 20 | 100 | 5 | 32 |

Comparison: Which Minnexon Tool Fits Your Job?

To help you rank for “Thread Mill Selection” queries, here is a guide tailored to your specific materials.

| Requirement | Single-Form (Single-Point) | Multi-Form (Multi-Tooth) |

| Best For… | Prototyping & Small Batches | High-Volume Serial Production |

| Material Issue | Low Spindle Power setups | Preventing Work Hardening in Titanium |

| Thread Pitch | One tool for Multi pitches (Universal) | Fixed Pitch (One tool per size) |

| Cut Force | Low radial pressure | Higher pressure (Requires rigid holding) |

| Cost Benefit | Lower initial tool cost | Lowest cost per threaded hole |

Specialized Applications

Our customers use Minnexon Multi-Form mills for these specific demanding components:

- Electronics Packaging: High-precision threading in Kovar housings for optical and electronic packages.

- Medical Implants: Mass production of Titanium bone plates and screws where surface integrity is non-negotiable.

- Aerospace Fluid Control: Threading Nickel-alloy valve bodies that require zero leakage.

Why Minnexon is Your Strategic Partner?

We understand the pressure of high-value manufacturing.

- Inventory for Exotic Alloys: We stock specific geometries optimized for exotic materials, ready for global express shipping.

- Direct-from-Factory Savings: Control your production costs by buying premium quality directly from the source.

- 100% Optical Inspection: We guarantee that every flute is perfect. No surprises when you touch off the tool.

- Custom Solutions: Need a non-standard diameter for a specific aerospace thread spec? We offer custom manufacturing with a 7-10 day turnaround.

Related products

Get in Touch

We will provide you with feedback within 24 hours.