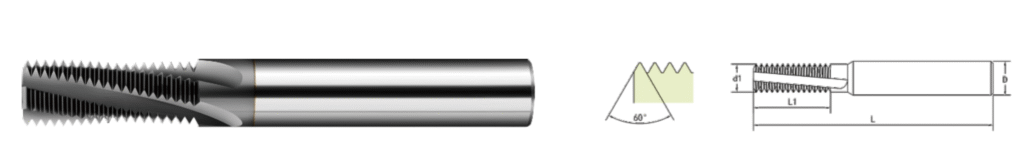

NPT Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Explore solid carbide multi-form thread milling cutters for precise internal and external 60° NPT threads.

- Available in uncoated, AlTiN, TiAlN, and DLC coatings.

- Supports both right-hand and left-hand threads.

- High performance at competitive prices.

Overview

The NPT Multi-Form Thread Milling Cutter is designed for accurate and reliable machining of National Pipe Taper (NPT) threads. It forms the complete thread profile, including crest and root, in a single pass. This ensures a tight seal and smooth thread fit. The cutter is made for CNC machines that use helical interpolation. It offers high precision and long tool life, even in tough materials.

Key Features

Accurate Thread Form: The multi-form design shapes the entire thread profile. It gives consistent pitch, depth, and taper, which is important for pipe connections that must seal under pressure.

Long Tool Life: The cutter is made from high-quality carbide with a durable coating. It can handle repeated cutting without losing sharpness.

High Efficiency: It cuts the full profile in one pass, reducing machining time and improving productivity.

Wide Material Compatibility: You can use it on steel, stainless steel, brass, aluminum, and other common materials used for pipe fittings.

Perfect Thread Fit: The full-profile design produces a clean and complete NPT thread. It helps avoid leaks and ensures a proper mechanical fit.

Technical Specifications (Customizable)

| NPT | tpi | d1/mm | L1/mm | D/mm | L/mm | F | Drill dia. (mm) |

|---|---|---|---|---|---|---|---|

| NPT1/16-27 | 27 | 5.3 | 10 | 6 | 60 | 3 | 6.3 |

| NPT1/8-27 | 27 | 7.95 | 15 | 8 | 65 | 3 | 8.5 |

| NPT1/4-18 | 18 | 9.9 | 15.5 | 10 | 75 | 4 | 11.1 |

| NPT3/8-18 | 18 | 11.9 | 16 | 12 | 75 | 4 | 14.5 |

| NPT1/2-14 | 14 | 11.9 | 25 | 12 | 83 | 4 | 17.7 |

| NPT3/4-14 | 14 | 11.9 | 25 | 12 | 83 | 4 | 23 |

| NPT1/2-14 | 14 | 15.95 | 30 | 16 | 100 | 5 | 17.7 |

| NPT3/4-14 | 14 | 15.95 | 30 | 16 | 100 | 5 | 23 |

| NPT1 -11.5 | 11.5 | 15.9 | 33 | 16 | 100 | 5 | 29 |

| NPT1-11.5 | 11.5 | 19.9 | 33 | 20 | 100 | 5 | 29 |

Why Choose an NPT Multi-Form Thread Milling Cutter

Buyers often want tools that reduce setup time, improve accuracy, and lower tool costs.

This cutter meets all three needs. One tool can produce multiple NPT sizes by adjusting the CNC path. You can achieve consistent thread quality without changing tools often. It is also safer than using traditional pipe taps, which can break in deep holes.

Applications

NPT and NPTF tapered pipe threads

Hydraulic and pneumatic components

Oil and gas fittings

Plumbing and fluid systems

CNC machining centers and automated production lines

FAQs

1. What does “multi-form” mean?

It means the cutter forms the complete thread shape, including the top and bottom of the thread. You get a finished thread without extra passes.

2. Can I use it for both internal and external threads?

Yes. It works for both internal and external NPT threads if the correct tool path is used.

3. What machine do I need?

You need a CNC milling machine that supports helical interpolation. Most modern CNC centers have this function.

4. What materials can it cut?

It can cut a wide range of metals such as mild steel, stainless steel, aluminum, copper, and brass.

5. How long does the tool last?

Tool life depends on material hardness and cutting parameters, but the carbide and coating give excellent wear resistance for long use.

Related products

-

NPTF Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

BSPP(G) Multi-Form 55 degree Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

BSPP/BSPT Single-Form 55 Degree Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

BSPT Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more

Get in Touch

We will provide you with feedback within 24 hours.