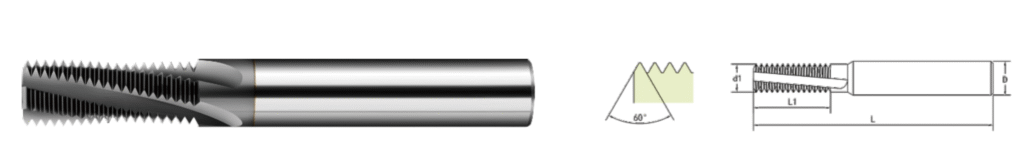

NPTF Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Explore solid carbide multi-form thread milling cutters for precise internal and external 60° NPTF threads.

- Available in uncoated, AlTiN, TiAlN, and DLC coatings.

- Supports both right-hand and left-hand threads.

- High performance at competitive prices.

Overview

The NPTF Multi-Form Thread Milling Cutter is a high-performance cutting tool made for fast and precise production of National Pipe Taper Fuel (NPTF) threads. It uses multiple cutting edges that shape the full thread form in one quick cycle. This design helps you save machining time and achieve consistent thread quality across all parts. It is an ideal choice for CNC users who need speed, reliability, and repeatable results.

Key Features

Fast and Efficient Cutting: The multi-form design has several thread profiles on the cutter. These profiles cut multiple thread pitches at once, making production faster and reducing total machining time.

Consistent Thread Accuracy: Every thread is formed with stable geometry and perfect taper. The cutter ensures a tight and leak-free fit, which is important for fuel, hydraulic, and pneumatic connections.

Reduced Tool Changes: One cutter can produce multiple NPTF thread sizes with simple CNC adjustments. This saves setup time and lowers tool inventory costs.

Reliable Performance: The cutter is made from premium micro-grain carbide with a hard coating for long wear life. It performs well on both soft and hard metals.

Smooth Surface Finish: The optimized edge design produces clean threads without burrs or chatter. This improves sealing performance and reduces post-processing work.

Technical Specifications (Customizable)

| Thread Size | Tpi | d1/mm | L1/mm | D/mm | L/mm | Flutes | Drill dia. (mm) |

|---|---|---|---|---|---|---|---|

| NPTF1/16-27 | 27 | 5.9 | 10 | 6 | 50 | 3 | 6.3 |

| NPTF1/8-27 | 27 | 7.95 | 15 | 8 | 60 | 4 | 8.4 |

| NPTF1/4-18 | 18 | 9.9 | 14.8 | 10 | 75 | 4 | 11.1 |

| NPTF3/8-18 | 18 | 11.95 | 14.8 | 12 | 75 | 4 | 14.7 |

| NPTF1/2-14 | 14 | 15.95 | 25 | 16 | 100 | 5 | 17.9 |

| NPTF1-11.5 | 11.5 | 19.6 | 23 | 20 | 100 | 5 | 29 |

| NPTF1-11.5 | 11.5 | 15.9 | 33 | 16 | 100 | 5 | 29 |

What Users Want to Know

1. What makes a multi-form cutter different?

A multi-form cutter has several thread profiles on one tool. It cuts more of the thread with each rotation, which makes it faster than a single-form cutter.

2. Can I use it for both blind and through holes?

Yes. It works for both, as long as the correct tool path and cutting parameters are used.

3. Is it only for NPTF threads?

It is designed for NPTF threads but can also be used for standard NPT threads if accuracy requirements are not as tight.

4. What materials does it support?

It can machine steel, stainless steel, aluminum, brass, and other common industrial alloys.

5. How can I get the best tool life?

Use proper coolant, correct spindle speed, and stable cutting depth. Follow the manufacturer’s cutting data for the best results.

6. Why This Tool is a Good Investment?

The NPTF Multi-Form Thread Milling Cutter helps manufacturers produce tight-sealing pipe threads with speed and reliability. It increases output, maintains high accuracy, and reduces tool wear. Buyers appreciate that it shortens production time while keeping the thread quality consistent. It is a trusted solution for shops focused on productivity and precision.

Related products

-

NPT Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

BSPP(G) Multi-Form 55 degree Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

BSPP/BSPT Single-Form 55 Degree Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

BSPT Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more

Get in Touch

We will provide you with feedback within 24 hours.