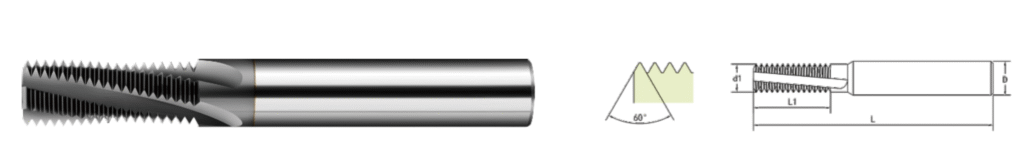

BSPT Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

- Selected solid carbide tungsten steel material, manufactured using German Walter equipment.

- Multiple coating options available, including uncoated, AlTiN, TiAlN, and DLC coatings.

- Suitable for machining 55° BSPT (Rc) threads, with a 1:16 taper for precise and reliable threading.

- Applicable for both left-hand and right-hand threads, as well as internal and external threads.

Product Overview

The RC Full-Form Thread Mill (also known as PT Thread Mill or BSPT Thread Mill) is a high-performance threading solution made from premium tungsten carbide (solid carbide). Designed for both CNC machining and precision manufacturing, this tool enables accurate threading of internal and external threads, including both left-hand and right-hand directions. With its full-profile cutting design, it delivers exceptional precision and efficiency in a single operation.

Key Features

Solid carbide (tungsten carbide) construction for superior hardness and stability.

Full-form thread profile for faster cycle times and high-accuracy results.

Cuts internal & external threads, supporting both left-hand and right-hand threading.

Compatible with a wide range of materials, from soft aluminum to superalloys.

Excellent surface finish, ensuring tight tolerances and reduced post-processing.

Long tool life with the right coating selection, even in difficult-to-machine alloys.

Material Compatibility & Coating Recommendations

Choosing the correct coating based on the material significantly improves cutting performance, chip evacuation, and tool longevity.

| Workpiece Material | Recommended Coating Type |

|---|---|

| Aluminum / Copper | DLC or uncoated |

| 45# Carbon Steel | TiAlN or TiCN |

| Stainless Steel (304/316) | AlCrN or TiSiN |

| P20 Mold Steel | TiAlN or nano-coating |

| Cast Iron | TiCN or TiN |

| Titanium Alloys | TiSiN or DLC |

| High-Temp Alloys (Inconel, Hastelloy) | AlCrN or advanced nano coatings |

Applications

The RC Full-Form Thread Mill is widely used in:

Aerospace & Automotive components

Precision molds and dies

Hydraulic and pneumatic parts

General CNC machining of high-strength metals

Why Choose Our RC Full-Tooth Thread Mill?

Compared to single-tooth or triple-tooth thread mills, the RC full-tooth design allows for faster production cycles, greater consistency, and higher efficiency in threading operations. Whether you need to machine metric, imperial, or custom thread profiles, this tool ensures accuracy, durability, and versatility.

The RC Full-Form Tungsten Carbide Thread Mill is the ideal choice for manufacturers who require precision, efficiency, and flexibility in their threading operations. With coating options tailored to copper, steel, stainless steel, cast iron, titanium, and high-temperature alloys, it is a truly universal solution for modern CNC machining.

Technical Specifications (Customizable)

| RC/BSPT | tpi | P | d1/mm | L1/mm | D/mm | L/mm | F | Drill dia. (mm) |

|---|---|---|---|---|---|---|---|---|

| RC1/16-28 | 28 | 0.907 | 5.8 | 12 | 6 | 60 | 3 | 6.7 |

| RC1/8-28 | 28 | 0.907 | 7.95 | 20 | 8 | 65 | 3 | 8.7 |

| RC1/4-19 | 19 | 1.337 | 9.9 | 26.7 | 10 | 75 | 4 | 11.8 |

| RC3/8-19 | 19 | 1.337 | 11.9 | 30 | 12 | 75 | 4 | 15.2 |

| RC1/2-14 | 14 | 1.814 | 11.9 | 33 | 12 | 83 | 4 | 19 |

| RC3/4-14 | 14 | 1.814 | 11.9 | 33 | 12 | 83 | 4 | 19 |

| RC1/2-14 | 14 | 1.814 | 15.9 | 40 | 16 | 100 | 5 | 19 |

| RC3/4-14 | 14 | 1.814 | 15.9 | 40 | 16 | 100 | 5 | 19 |

| RC1-11 | 11 | 2.309 | 15.9 | 42 | 16 | 100 | 5 | 30.7 |

| RC2-11 | 11 | 2.309 | 19.9 | 41.5 | 20 | 100 | 5 | 30.7 |

Related products

-

NPTF Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

NPT Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

BSPP(G) Multi-Form 55 degree Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

BSPP/BSPT Single-Form 55 Degree Thread Mill | Solid Carbide Thread Milling Cutter

Read more

Get in Touch

We will provide you with feedback within 24 hours.