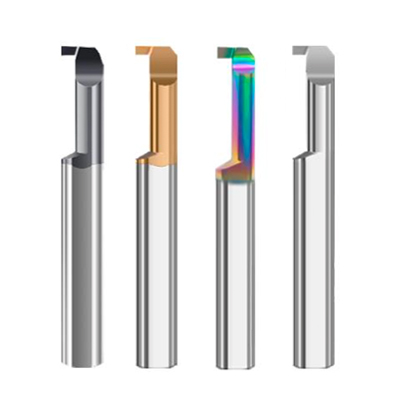

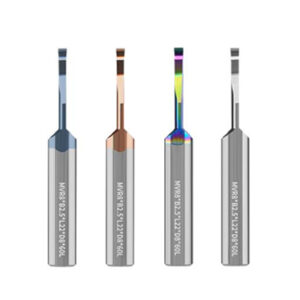

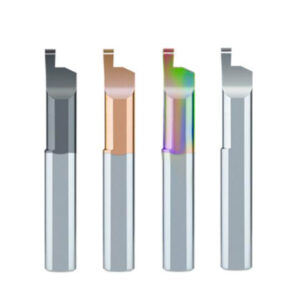

Solid Carbide Internal Grooving Tool | MGR Carbide Grooving Bar for CNC Lathe

High quality solid carbide internal grooving tools for CNC lathes.

Durable, precise, and stable for internal slotting and cutting various metals.

A solid carbide internal grooving tool, also known as a carbide grooving bar or carbide internal slotting tool, is used to cut grooves, recesses, and internal profiles inside holes. It is made from solid tungsten carbide for high strength, long wear resistance, and excellent cutting performance. This tool is suitable for CNC lathes, turning centers, and other precision machining equipment.

Technical Specifications (Customizable)

| Ordering Code | L/mm | D/mm | L1/mm | B/mm | H/mm | d/mm | Min. Dia./mm |

|---|---|---|---|---|---|---|---|

| MGR3 B0.5 L10 | 50 | 4 | 10 | 0.5 | 1 | 2.9 | 3.1 |

| MGR3 B0.7 L10 | 50 | 4 | 10 | 0.7 | 1 | 2.9 | 3.1 |

| MGR3 B1 L10 | 50 | 4 | 10 | 1 | 1 | 2.9 | 3.1 |

| MGR3 B1.5 L10 | 50 | 4 | 10 | 1.5 | 1 | 2.9 | 3.1 |

| MGR4 B0.5 L10 | 50 | 4 | 10 | 0.5 | 1 | 3.9 | 4.1 |

| MGR4 B0.7 L10 | 50 | 4 | 10 | 0.7 | 1 | 3.9 | 4.1 |

| MGR4 B1 L10 | 50 | 4 | 10 | 1 | 1.5 | 3.9 | 4.1 |

| MGR4 B1.5 L10 | 50 | 4 | 10 | 1.5 | 1.5 | 3.9 | 4.1 |

| MGR4 B2 L10 | 50 | 4 | 10 | 2 | 1.5 | 3.9 | 4.1 |

| MGR4 B0.5 L15 | 50 | 4 | 15 | 0.5 | 1 | 3.9 | 4.1 |

| MGR4 B0.7 L15 | 50 | 4 | 15 | 0.7 | 1 | 3.9 | 4.1 |

| MGR4 B1 L15 | 50 | 4 | 15 | 1 | 1.5 | 3.9 | 4.1 |

| MGR4 B1.5 L15 | 50 | 4 | 15 | 1.5 | 1.5 | 3.9 | 4.1 |

| MGR4 B2 L15 | 50 | 4 | 15 | 2 | 1.5 | 3.9 | 4.1 |

| MGR5 B1 L15 | 50 | 5 | 15 | 1 | 1.5 | 4.9 | 5.1 |

| MGR5 B1.5 L15 | 50 | 5 | 15 | 1.5 | 1.5 | 4.9 | 5.1 |

| MGR5 B2 L15 | 50 | 5 | 15 | 2 | 1.5 | 4.9 | 5.1 |

| MGR5 B1 L22 | 50 | 5 | 22 | 1 | 1.5 | 4.9 | 5.1 |

| MGR5 B1.5 L22 | 50 | 5 | 22 | 1.5 | 1.5 | 4.9 | 5.1 |

| MGR5 B2 L22 | 50 | 5 | 22 | 2 | 1.5 | 4.9 | 5.1 |

| MGR6 B1 L15 | 50 | 6 | 15 | 1 | 2 | 5.9 | 6.1 |

| MGR6 B1.5 L15 | 50 | 6 | 15 | 1.5 | 2 | 5.9 | 6.1 |

| MGR6 B2 L15 | 50 | 6 | 15 | 2 | 2 | 5.9 | 6.1 |

| MGR6 B1 L22 | 50 | 6 | 22 | 1 | 2 | 5.9 | 6.1 |

| MGR6 B1.5 L22 | 50 | 6 | 22 | 1.5 | 2 | 5.9 | 6.1 |

| MGR6 B2 L22 | 50 | 6 | 22 | 2 | 2 | 5.9 | 6.1 |

| MGR8 B1 L15 | 60 | 8 | 15 | 1 | 2 | 7.9 | 8.1 |

| MGR8 B1.5 L15 | 60 | 8 | 15 | 1.5 | 2.5 | 7.9 | 8.1 |

| MGR8 B2 L15 | 60 | 8 | 15 | 2 | 2.5 | 7.9 | 8.1 |

| MGR8 B2.5 L15 | 60 | 8 | 15 | 2.5 | 3 | 7.9 | 8.1 |

| MGR8 B3 L15 | 60 | 8 | 15 | 3 | 3 | 7.9 | 8.1 |

| MGR8 B1 L22 | 60 | 8 | 22 | 1 | 2 | 7.9 | 8.1 |

| MGR8 B1.5 L22 | 60 | 8 | 22 | 1.5 | 2.5 | 7.9 | 8.1 |

| MGR8 B2 L22 | 60 | 8 | 22 | 2 | 2.5 | 7.9 | 8.1 |

| MGR8 B2.5 L22 | 60 | 8 | 22 | 2.5 | 3 | 7.9 | 8.1 |

| MGR8 B3 L22 | 60 | 8 | 22 | 3 | 3 | 7.9 | 8.1 |

| MGR10 B1 L15 | 75 | 10 | 15 | 1 | 2.5 | 9.9 | 10.1 |

| MGR10 B1.5 L15 | 75 | 10 | 15 | 1.5 | 3.5 | 9.9 | 10.1 |

| MGR10 B2 L15 | 75 | 10 | 15 | 2 | 4 | 9.9 | 10.1 |

| MGR10 B2.5 L15 | 75 | 10 | 15 | 2.5 | 4 | 9.9 | 10.1 |

| MGR10 B3 L15 | 75 | 10 | 15 | 3 | 4 | 9.9 | 10.1 |

| MGR10 B1 L30 | 75 | 10 | 30 | 1 | 2.5 | 9.9 | 10.1 |

| MGR10 B1.5 L30 | 75 | 10 | 30 | 1.5 | 3.5 | 9.9 | 10.1 |

| MGR10 B2 L30 | 75 | 10 | 30 | 2 | 4 | 9.9 | 10.1 |

| MGR10 B2.5 L30 | 75 | 10 | 30 | 2.5 | 4 | 9.9 | 10.1 |

| MGR10 B3 L30 | 75 | 10 | 30 | 3 | 4 | 9.9 | 10.1 |

Product Features and Benefits

- High precision: Cuts grooves and recesses accurately with smooth edges.

- Durable and strong: Solid carbide material resists wear and heat during cutting.

- Stable performance: Reduces vibration for consistent groove quality.

- Versatile use: Suitable for steel, stainless steel, cast iron, aluminum, and copper.

- Long tool life: Maintains sharp edges longer, lowering replacement costs.

How to Use

Mount the carbide internal grooving tool securely in the tool holder. Adjust the tool length for proper groove depth. Select the correct insert or blade for the material. Use proper cutting speed and feed rate. Apply coolant to improve tool life and surface finish.

Common Questions

Q1: How do I choose the right carbide internal grooving tool?

A: Choose a tool size that fits your hole diameter and groove width. Ensure the shank fits your lathe holder.

Q2: Can it cut deep internal grooves?

A: Yes, but for very deep grooves, use a longer grooving bar or step grooving to reduce vibration.

Q3: What materials can I machine?

A: Steel, stainless steel, cast iron, aluminum, and copper can be machined.

Q4: How can I extend the tool life?

A: Use proper cutting parameters, reduce vibration, and apply cutting oil or coolant.

Related products

-

Solid Carbide Deep Face Grooving Tool | MVR Carbide Deep Face Grooving Bar

Read more -

Solid Carbide Internal Face Grooving Tool | MFR Carbide Face Grooving Bar

Read more -

Solid Carbide Internal Full Radius Grooving Tool | MKR Carbide Full Radius Grooving Bar

Read more -

Solid Carbide Internal Boring Tool | MTR Carbide Boring Bar for CNC Lathe

Read more

Get in Touch

We will provide you with feedback within 24 hours.