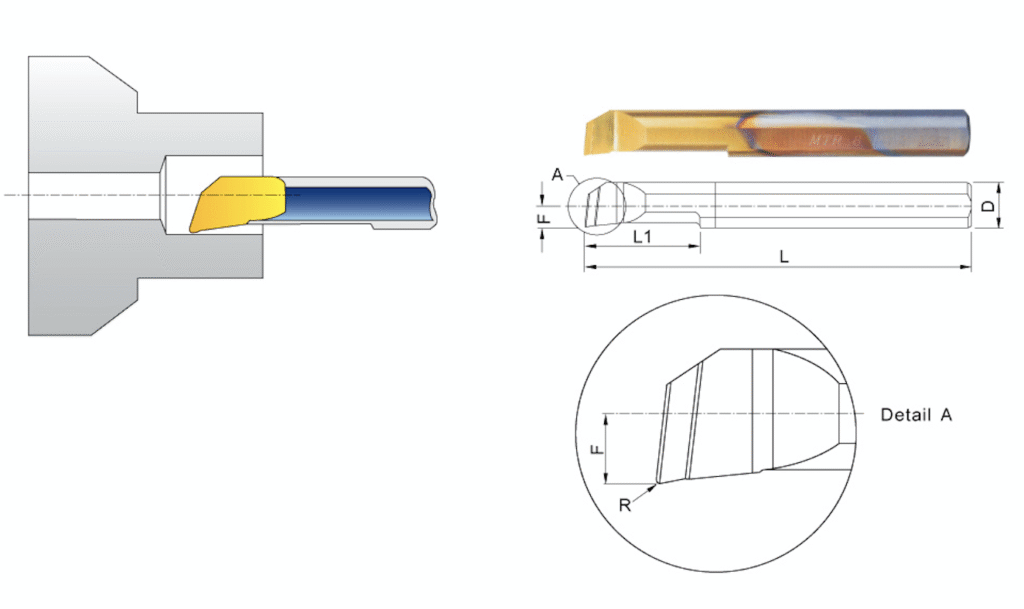

Solid Carbide Internal Profiling Tool for Precision Boring

Engineered for Stainless Steel, Titanium, and High-Temperature Alloys

Achieve exceptional surface finish and dimensional control in internal profiles with our high-performance solid carbide internal profiling tool—a specialized solution in the precision boring tool category. Designed for deep hole finishing, small-diameter profiling, and tight-tolerance internal features, this tool has been extensively tested and optimized for difficult-to-machine materials.

Key Features

Premium Tungsten Carbide Substrate

Manufactured from ultra-fine grain carbide, ensuring rigidity and vibration resistance during deep internal cuts.Application-Specific Cutting Geometries

Different edge designs tailored for stainless steel, titanium, and nickel-based alloys—helping minimize built-up edge (BUE) and improve chip evacuation.High-Performance Coatings

Available with TiSiN, AlTiN, or diamond-like carbon (DLC) coatings for optimized heat resistance and extended tool life in demanding environments.Stable Internal Machining

Rigid shank design and optimized flute geometry reduce chatter, ensure surface finish quality, and enhance dimensional repeatability.

Why Choose This Tool?

Field-Tested Across Thousands of Setups

Proven machining stability and finish results in real-world production environments—especially for medical, aerospace, and precision engineering sectors.Custom Geometry Available

We support small-batch or custom tool development for specific internal profiles or narrow bore requirements.Ideal for:

Internal grooves and undercuts

Small bore finishing

Internal radius transitions

Surface-critical internal features

Typical Applications

| Material | Performance Focus |

|---|---|

| SUS 304 / 316 | Anti-buildup geometry, chip control |

| Titanium Ti6Al4V | Vibration resistance, heat dissipation |

| Inconel / Hastelloy | Wear-resistant edge and stable feed |

| 45# / P20 / Cast Iron | High-speed finishing, smooth entry |

Specification (Unit: mm)

| Order Code | Dia | OAL | L1 | R | F | Min.Bore Dia |

| MTR 2 R0.15 L5 | 4 | 50 | 5 | 0.15 | 0.8 | 2.1 |

| MTR 2 R0.15 L10 | 4 | 50 | 10 | 0.15 | 0.8 | 2.1 |

| MTR 3 R0.05 L10 | 4 | 50 | 10 | 0.05 | 1.3 | 3.1 |

| MTR 3 R0.05 L15 | 4 | 50 | 15 | 0.05 | 1.3 | 3.1 |

| MTR 3 R0.2 L10 | 4 | 50 | 10 | 0.2 | 1.3 | 3.1 |

| MTR 3 R0.2 L15 | 4 | 50 | 15 | 0.2 | 1.3 | 3.1 |

| MTR 4 R0.2 L10 | 4 | 50 | 10 | 0.2 | 1.7 | 4.1 |

| MTR 4 R0.2 L15 | 4 | 50 | 15 | 0.2 | 1.7 | 4.1 |

| MTR 5 R0.2 L15 | 5 | 50 | 15 | 0.2 | 2.1 | 5.1 |

| MTR 5 R0.2 L22 | 5 | 50 | 22 | 0.2 | 2.1 | 5.1 |

| MTR 6 R0.2 L15 | 6 | 50 | 15 | 0.2 | 2.8 | 6.1 |

| MTR 6 R0.2 L22 | 6 | 50 | 22 | 0.2 | 2.8 | 6.1 |

| MTR 8 R0.2 L15 | 8 | 60 | 15 | 0.2 | 3.8 | 8.1 |

| MTR 8 R0.2 L22 | 8 | 60 | 22 | 0.2 | 3.8 | 8.1 |

Get in Touch

We will provide you with feedback within 24 hours.