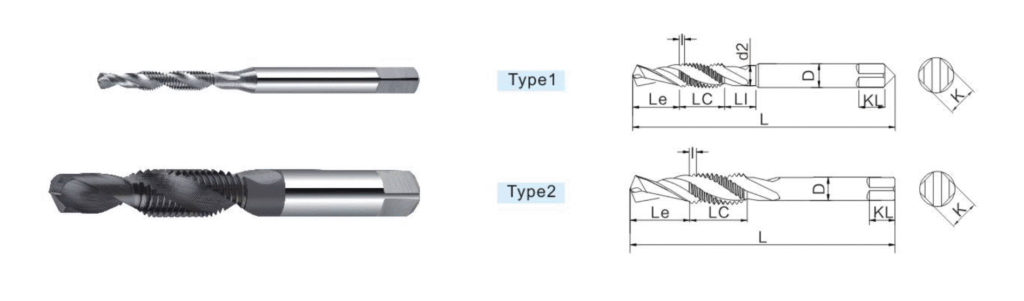

Solid Carbide Spiral Flute Drill-Tap Combo Tool

One-Step Threading with High Precision and Speed

Product Overview

The Solid Carbide Spiral Flute Drill-Tap Combo Tool is a high-efficiency, all-in-one cutting solution designed to drill and tap threads in a single pass. Engineered from premium tungsten carbide, this combination tool reduces machining time, improves alignment accuracy, and is ideal for automated CNC operations, especially in high-volume production environments.

Equipped with a spiral flute geometry and precision-ground thread section, this tool ensures excellent chip evacuation, minimal tool deflection, and clean internal threads, even in blind holes. It is particularly effective for materials such as aluminum, copper, non-ferrous alloys, and mild steels.

Key Features

2-in-1 Functionality: Performs both drilling and tapping in a single operation

Material: Ultra-fine grain solid tungsten carbide for superior wear resistance

Spiral Flute Design: Ensures efficient chip removal and smooth threading

High Precision: Tight tolerance control for thread accuracy and consistency

Ideal for CNC Machining: Reduces cycle time and tool changes

Applications

Ideal for high-efficiency threading in blind or through holes

Used in electronics casings, aerospace parts, aluminum components, and precision mechanical assemblies

Compatible with aluminum, brass, copper, plastics, and mild steels

Suitable for vertical/horizontal CNC machines, robotic arms, and multi-axis machining centers

Advantages

Streamlined workflow – Drill and tap without changing tools

Consistent, clean threads – No secondary tapping needed

Reduced machining time – Up to 50% faster than traditional methods

Enhanced accuracy – Drill and tap alignment in one setup

Long tool life – Durable carbide body withstands high cutting loads

Usage Recommendations

Ensure proper RPM/feed rate calibration based on material and size

Use appropriate coolant or MQL to improve surface finish and reduce tool wear

Designed primarily for ductile or soft metals – not recommended for hardened steel

For blind holes, verify that thread depth doesn’t exceed flute length

Technical Specifications (Customizable)

| Thread | Prec. | l | Le | Lc | L | D | Z | ∠ | LK | K | L1 | d2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M2 * 0.4 | 6H | 2.5P | 6 | 10 | 52 | 3 | 2 | 30 | 5 | 2.5 | 5 | 1.9 |

| M2.5 * 0.45 | 6H | 2.5P | 7 | 10 | 55 | 3 | 2 | 30 | 5 | 2.5 | 5 | 2.4 |

| M3 * 0.5 | 6H | 2.5P | 7 | 12 | 56 | 4 | 2 | 30 | 6 | 3.2 | 5 | 2.8 |

| M4 * 0.7 | 6H | 2.5P | 7 | 12 | 56 | 4 | 2 | 30 | 6 | 3.2 | / | / |

| M5 * 0.8 | 6H | 2.5P | 9 | 15 | 65 | 5 | 2 | 30 | 7 | 4 | / | / |

| M6 * 1 | 6H | 2.5P | 12 | 18 | 70 | 6 | 2 | 30 | 8 | 4.5 | / | / |

| M8 * 1.25 | 6H | 2.5P | 15 | 20 | 75 | 8 | 2 | 30 | 9 | 6 | / | / |

| M10 * 1.5 | 6H | 2.5P | 18 | 25 | 85 | 10 | 2 | 30 | 10 | 8 | / | / |

| M12 * 1.75 | 6H | 2.5P | 20 | 25 | 92 | 12 | 2 | 30 | 13 | 10 | / | / |

Get in Touch

We will provide you with feedback within 24 hours.