Tri-Form Thread Mills for Titanium, Nickel & Kovar

Minnexon Tri-Form Thread Mills reduce cutting pressure in Titanium and Kovar. The perfect balance of speed and stability for thin-wall machining.

- Internal and External: Safely machine both internal and external threads.

- Left and Right Hand: You can create right-hand or left-hand threads simply by changing the CNC program.

The “Goldilocks” Zone: Speed Meets Stability

Our Tri-Form design features three cutting zones (or a skip-tooth geometry) to dramatically reduce contact area compared to full-profile cutters.

1. Minimized Radial Cutting Pressure

Titanium has a low modulus of elasticity, meaning it “springs back.” High cutting pressure causes dimensional errors.

- The Advantage: By engaging fewer teeth than a full multi-form cutter, the Tri-Form reduces lateral force.

- The Result: You get perfectly straight threads even in long-reach applications, eliminating the “bell-mouth” or tapered effect common in deep hole thread milling.

2. Superior Chip Evacuation in Deep Holes

In sticky materials like Nickel Alloys and Kovar, chips packing into the flutes is a major cause of tool breakage.

- More Space: The Tri-Form geometry provides extra flute space (gullet) between cutting teeth.

- Coolant Flow: This allows our internal coolant to flush chips out of deep blind holes effectively, preventing re-cutting of chips.

3. The Minnexon Golden Coating Advantage

Just like our other series, these tools feature our strategic partner’s Golden Heat-Resistant Coating.

- It prevents edge build-up (BUE) in sticky alloys.

- It reduces friction, further lowering the torque required from your spindle.

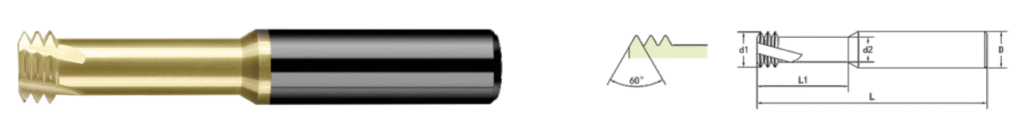

Technical Specifications (Customizable)

| M coarse | M fine | P (mm) | d1 (mm) | L1 (mm) | D (mm) | L (mm) | F (mm) | Drill dia. (mm) |

|---|---|---|---|---|---|---|---|---|

| M1×0.25 | 0.25 | 0.73 | 2.3 | 4 | 50 | 3 | 0.75 | |

| M1.2×0.25 | 0.25 | 0.92 | 3.3 | 4 | 50 | 3 | 0.95 | |

| M1.4×0.3 | 0.3 | 1.05 | 3.2 | 4 | 50 | 3 | 1.1 | |

| M1.6×0.35 | 0.35 | 1.21 | 3.5 | 4 | 50 | 3 | 1.25 | |

| M1.7×0.35 | 0.35 | 1.3 | 4.3 | 4 | 50 | 3 | 1.35 | |

| M1.8×0.35 | 0.35 | 1.4 | 4 | 4 | 50 | 3 | 1.45 | |

| M2×0.4 | 0.4 | 1.54 | 4.5 | 4 | 50 | 3 | 1.6 | |

| M2.2×0.45 | 0.45 | 1.65 | 5 | 4 | 50 | 3 | 1.75 | |

| M2.5×0.45 | 0.45 | 1.96 | 5.5 | 4 | 50 | 3 | 2.05 | |

| M2.5×0.35 | 0.35 | 1.96 | 7.5 | 4 | 50 | 3 | 2.15 | |

| M3×0.5 | 0.5 | 2.42 | 7 | 4 | 50 | 3 | 2.5 | |

| M3.5×0.6 | 0.6 | 2.75 | 9 | 4 | 50 | 3 | 2.9 | |

| M3.5×0.35 | 0.35 | 3 | 5 | 4 | 50 | 3 | 3.15 | |

| M3×0.35 | 0.35 | 2.5 | 6 | 4 | 50 | 3 | 2.65 | |

| M4×0.5 | 0.5 | 3.4 | 8 | 4 | 50 | 3 | 3.5 | |

| M4.5×0.75 | 0.75 | 3.5 | 11 | 4 | 50 | 3 | 3.75 | |

| M4×0.7 | 0.7 | 3.15 | 10 | 4 | 50 | 3 | 3.3 | |

| M4×0.35 | 0.35 | 3.3 | 6 | 4 | 50 | 3 | 3.65 | |

| M5×0.5 | 0.5 | 3.9 | 8 | 4 | 50 | 3 | 4.5 | |

| M5×0.75 | 0.75 | 3.9 | 8 | 4 | 50 | 3 | 4.25 | |

| M5×0.8 | 0.8 | 4 | 12 | 6 | 50 | 3 | 4.2 | |

| M5×0.8 | 0.8 | 3.95 | 12 | 4 | 50 | 3 | 4.2 | |

| M6×0.5 | 0.5 | 4.8 | 13 | 6 | 50 | 3 | 5.5 | |

| M6×0.75 | 0.75 | 5 | 13 | 6 | 50 | 3 | 5.25 | |

| M6×1.0 | 1 | 3.95 | 14 | 4 | 50 | 3 | 5 | |

| M6×1.0 | 1 | 4.75 | 13 | 6 | 50 | 3 | 5 | |

| M8×0.5 | 0.5 | 5.95 | 16 | 6 | 50 | 4 | 7.5 | |

| M8×0.75 | 0.75 | 5.95 | 20 | 6 | 50 | 3 | 7.25 | |

| M8×1.0 | 1 | 5.9 | 20 | 6 | 60 | 3 | 7 | |

| M8×1.25 | 1.25 | 5.95 | 17.5 | 6 | 50 | 3 | 6.75 | |

| M10×0.5 | 0.5 | 7.95 | 25 | 8 | 60 | 4 | 9.5 | |

| M10×0.75 | 0.75 | 7.95 | 25 | 8 | 60 | 4 | 9.25 | |

| M10×1.0 | 1 | 7.9 | 21 | 8 | 60 | 4 | 9 | |

| M10×1.25 | 1.25 | 7.95 | 21 | 8 | 60 | 4 | 8.75 | |

| M10×1.5 | 1.5 | 7.9 | 22 | 8 | 60 | 4 | 8.5 | |

| M12×1.0 | 1 | 9.9 | 30 | 10 | 75 | 4 | 11 | |

| M12×1.5 | 1.5 | 9.9 | 30 | 10 | 75 | 4 | 10.5 | |

| M12×1.25 | 1.25 | 9.9 | 30 | 10 | 75 | 4 | 10.75 | |

| M12×1.75 | 1.75 | 9.9 | 28 | 10 | 75 | 4 | 10.25 | |

| M14×2.0 | 2 | 9.9 | 28 | 10 | 75 | 4 | 12 | |

| M16×1.5 | 1.5 | 11.9 | 35 | 12 | 75 | 4 | 14.5 | |

| M16×2.0 | 2 | 11.9 | 35 | 12 | 75 | 4 | 14 | |

| M18×2.5 | 2.5 | 13.9 | 40 | 14 | 83 | 5 | 15.5 | |

| M20×2.5 | 2.5 | 15.9 | 50 | 16 | 100 | 6 | 17.5 | |

| M24×3.0 | 3 | 15.9 | 50 | 16 | 100 | 6 | 21 | |

| M30×3.5 | 3.5 | 15.9 | 50 | 16 | 100 | 6 | 26.5 |

Comparison: Which Minnexon Tool Fits Your Job?

To help you rank for “Thread Mill Selection” queries, here is a guide tailored to your specific materials.

| Requirement | Single-Form (Single-Point) | Multi-Form (Multi-Tooth) |

| Best For… | Prototyping & Small Batches | High-Volume Serial Production |

| Material Issue | Low Spindle Power setups | Preventing Work Hardening in Titanium |

| Thread Pitch | One tool for Multi pitches (Universal) | Fixed Pitch (One tool per size) |

| Cut Force | Low radial pressure | Higher pressure (Requires rigid holding) |

| Cost Benefit | Lower initial tool cost | Lowest cost per threaded hole |

Frequently Asked Questions (FAQ)

Q1: When should I choose Tri-Form over Multi-Form?

A: Choose Tri-Form when you are experiencing chatter (vibration) or thread tapering with a Multi-Form tool. It is also the best choice for thin-walled parts (like sensor housings or aerospace fittings) where the pressure of a full cutter would deform the part.

Q2: Is the Tri-Form faster than a Single-Point tool?

A: Yes, significantly. While not as fast as a full Multi-Form, the Tri-Form typically cuts 3x faster than a Single-Point tool because it cuts three threads (or a wider band) per rotation, reducing the number of helical passes required.

Q3: Can this tool machine Kovar without rapid wear?

A: Kovar is abrasive. Our specific Golden Coating is designed to withstand this abrasiveness. The Tri-Form design also helps by reducing the heat generated in the cut, which is the primary killer of tool life in Kovar processing.

Q4: Do I need a high-pressure coolant system?

A: For deep hole threading in Titanium, high-pressure internal coolant (Through-Spindle Coolant) is highly recommended. It ensures chips don’t pack at the bottom of the hole. However, due to the open flute design of the Tri-Form, it performs better than Multi-Form tools if coolant pressure is limited.

Q5: Can I use this for both blind and through holes?

A: Yes. The Tri-Form geometry is excellent for both. For blind holes, make sure to leave clearance at the bottom, as specified in our catalog.

Why Minnexon is Your Strategic Partner?

We understand the pressure of high-value manufacturing.

- Inventory for Exotic Alloys: We stock specific geometries optimized for exotic materials, ready for global express shipping.

- Direct-from-Factory Savings: Control your production costs by buying premium quality directly from the source.

- 100% Optical Inspection: We guarantee that every flute is perfect. No surprises when you touch off the tool.

- Custom Solutions: Need a non-standard diameter for a specific aerospace thread spec? We offer custom manufacturing with a 7-10 day turnaround.

Related products

-

Single-Form Thread Mills for Titanium and Heat-Resistant Alloys

Read more -

Metric Multi-Form Thread Milling Cutter | Solid Carbide Thread Mill

Read more -

Metric Tri-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more -

Metric Single-Form Thread Mill | Solid Carbide Thread Milling Cutter

Read more

Get in Touch

We will provide you with feedback within 24 hours.