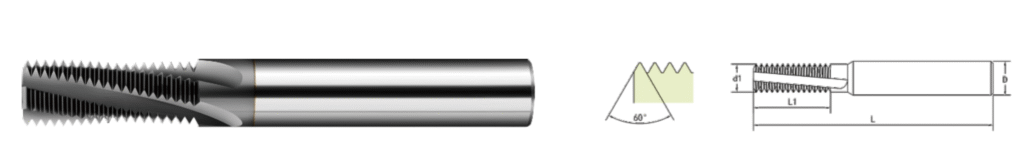

UN Multi-Form Thread Mill | Solid Carbide Thread Milling Cutter

Explore solid carbide multi-form thread milling cutters for precise internal and external 60° UN threads.

- Available in uncoated, AlTiN, TiAlN, and DLC coatings.

- Supports both right-hand and left-hand threads.

- High performance at competitive prices.

CNC Thread Milling for UN Threads

The Minnexon UN Multi-Form Thread Mill is a high-performance tool designed for professional machinists. We engineered this cutter to produce accurate Unified National (UN) threads in a wide range of materials.

Traditional tapping can be risky and slow. Our solid carbide thread mill offers a superior alternative. It provides excellent stability and long tool life. This tool is perfect for CNC applications where precision and reliability are critical.

Why Choose a Multi-Form Thread Mill?

This tool features a multi-form design. It has multiple teeth along the cutting length. This allows the tool to cut the full thread depth in a single pass around the hole. This method significantly reduces cycle time compared to single-point tools.

- Material: Premium Micro-Grain Solid Carbide

- Coating: uncoated, AlTiN, TiAlN, and DLC coatings

- Application: Internal & external threading for UN coarse and fine pitch standards

If you require tools for pipe threads, please view our NPT Thread Mills collection.

Technical Specifications (Customizable)

| UNS | UNC | UNF | TPI | d1/mm | L1/mm | D/mm | L/mm | Flutes |

|---|---|---|---|---|---|---|---|---|

| UNC8-32 | 32 | 3.2 | 11 | 4 | 50 | 3 | ||

| UNC10-32 | 32 | 3.8 | 10 | 4 | 50 | 3 | ||

| UNC6-32 | 32 | 2.56 | 8 | 4 | 50 | 3 | ||

| UNC10-24 | 24 | 3.6 | 11 | 4 | 50 | 3 | ||

| UNC4-40 | 40 | 2.13 | 7 | 4 | 50 | 3 | ||

| UNC2-56 | 56 | 1.65 | 6 | 4 | 50 | 3 | ||

| UNC1/4-20 | 20 | 4.9 | 13 | 6 | 50 | 3 | ||

| UNC5/16-18 | 18 | 6 | 17 | 6 | 60 | 3 | ||

| UNF1/4-28 | 28 | 4.6 | 15 | 6 | 50 | 3 | ||

| UNS10-48 | 48 | 4.1 | 12 | 6 | 50 | 3 | ||

| UNF5/16-24 | 24 | 5.9 | 17 | 6 | 60 | 3 | ||

| UNC3/8-16 | 16 | 7.65 | 20 | 8 | 65 | 3 | ||

| UNC7/16-14 | 14 | 7.6 | 23.6 | 8 | 60 | 4 | ||

| UNF5/16-24 | 24 | 6.88 | 21 | 8 | 65 | 3 | ||

| UNF5/8-18 | 18 | 7.95 | 20 | 8 | 65 | 4 | ||

| UNF3/8-32 | 32 | 7.9 | 20 | 8 | 65 | 4 | ||

| UNF3/8-24 | 24 | 7.4 | 20 | 8 | 65 | 4 | ||

| UNF7/16-28 | 28 | 7.9 | 20 | 8 | 60 | 4 | ||

| UNF1/2-20 | 20 | 9.9 | 25 | 10 | 75 | 4 | ||

| UNF9/16-18 | 18 | 10 | 30 | 10 | 75 | 4 | ||

| UNF7/16-20 | 20 | 8.5 | 23 | 10 | 75 | 4 | ||

| UNF3/4-20 | 20 | 9.95 | 25 | 10 | 75 | 4 | ||

| UNC1/2-13 | 13 | 9.5 | 25 | 10 | 75 | 4 | ||

| UNF9/16-24 | 24 | 11.9 | 30 | 12 | 75 | 4 | ||

| UNC5/8-11 | 11 | 11.95 | 35 | 12 | 83 | 4 | ||

| UNF9/16-18 | 18 | 11.95 | 30 | 12 | 83 | 4 | ||

| UNF7/8-14 | 14 | 12 | 30 | 12 | 75 | 4 | ||

| UNC9/16-12 | 12 | 11.8 | 28.6 | 12 | 75 | 4 | ||

| UNC3/4-20 | 20 | 11.9 | 30 | 12 | 75 | 4 | ||

| UNF7/8-28 | 28 | 12 | 30 | 12 | 75 | 4 | ||

| UNF3/4-16 | 16 | 12 | 28 | 12 | 75 | 4 | ||

| UNC3/4-10 | 10 | 14.5 | 40 | 16 | 100 | 5 | ||

| UNC7/8-9 | 9 | 15.95 | 45 | 16 | 100 | 4 | ||

| UNF3/4-16 | 16 | 15.9 | 40 | 16 | 100 | 5 | ||

| UNF7/8-14 | 14 | 15.9 | 40 | 16 | 100 | 5 | ||

| UNF1-12 | 12 | 16 | 40 | 16 | 100 | 5 | ||

| UNC1-8 | 8 | 16 | 40 | 16 | 100 | 5 | ||

| UNC1-8 | 8 | 19.95 | 50 | 20 | 100 | 5 |

How to use Thread Milling Cutters

Technical Advantages

- Superior Chip Control: One of the biggest challenges in threading is chip management. Taps often push long chips into the hole. This thread milling cutter produces small, manageable chips. The helical flute design evacuates these chips efficiently. This prevents re-cutting and ensures a high-quality surface finish.

- Safe and Secure Machining: A broken tap inside an expensive part is a nightmare. It often leads to scrapped parts. CNC thread milling eliminates this risk. If a thread mill breaks, the tool diameter is smaller than the thread minor diameter. You can easily remove the broken tool and save the workpiece.

- Versatility: A single tool can cut various thread diameters as long as the pitch is the same. This reduces the number of tools you need to keep in your inventory. For projects requiring metric specifications, check our ISO Metric Thread Mills.

Advice on Speeds and Feeds

We know that finding the correct thread milling speeds and feeds is essential for success. Since this is a solid carbide tool, it can handle higher surface footage (SFM) than High-Speed Steel (HSS) tools.

When programming your CNC machine, please remember a key rule. The feed rate at the cutting edge is different from the feed rate of the tool center. Most CNC controllers read the center feed rate. You must adjust your calculation for internal threading to maintain the correct chip load.

We recommend starting with a conservative feed rate and increasing it as you verify the process stability.

Suitable Materials

Our UN Multi-Form Thread Mill performs exceptionally well on:

- Carbon Steels

- Alloy Steels

- Stainless Steel

- Cast Iron

- Aluminum and Non-Ferrous Alloys

Get in Touch

We will provide you with feedback within 24 hours.