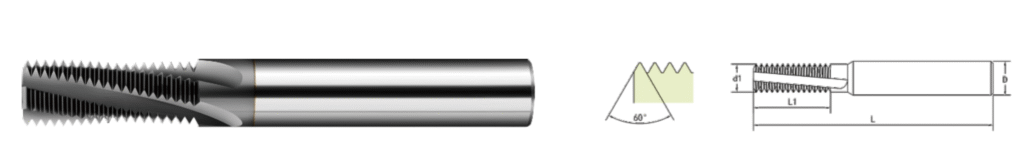

UN Solid Carbide Full-Profile Thread Mill

Solid Carbide Cutter for Left/Right-Hand Threads

Product Overview

The Solid Carbide UN Full-Profile Thread Mill is a premium threading solution engineered for Unified Thread Standard (UNC, UNF, UNEF) applications requiring full-profile threading with maximum precision and surface finish. Constructed from ultra-hard tungsten carbide, this tool is ideal for producing both internal and external threads, including right-hand and left-hand thread forms, across a variety of materials and thread depths.

Unlike single-point or partial-tooth cutters, the full-profile multi-tooth geometry cuts the entire thread profile in fewer passes, significantly reducing cycle times while maintaining high thread form accuracy.

Designed for CNC machines with helical interpolation capability, this thread mill offers consistent performance in mass production, precision tooling, and aerospace-grade thread fabrication.

Key Features

Thread Standard: Supports UNC, UNF, UNEF sizes

Geometry: Full-profile, multi-tooth design for faster cycle time

Thread Compatibility: Internal & external / right-hand & left-hand threads

Material: Solid tungsten carbide for superior durability

Custom Coatings: Application-specific PVD coatings improve tool performance

Material Compatibility & Coating Recommendations

Choosing the correct coating based on the material significantly improves cutting performance, chip evacuation, and tool longevity.

| Workpiece Material | Recommended Coating Type |

|---|---|

| Aluminum / Copper | DLC or uncoated |

| 45# Carbon Steel | TiAlN or TiCN |

| Stainless Steel (304/316) | AlCrN or TiSiN |

| P20 Mold Steel | TiAlN or nano-coating |

| Cast Iron | TiCN or TiN |

| Titanium Alloys | TiSiN or DLC |

| High-Temp Alloys (Inconel, Hastelloy) | AlCrN or advanced nano coatings |

Advantages

One-Pass Full Profile Cutting: Significantly reduces machining time compared to single-point cutters

Dimensional Accuracy: Ensures consistent thread pitch and full-profile conformity

Application Flexibility: Cuts both internal/external and LH/RH threads

Material Versatility: Optimized for soft metals, hardened steels, titanium, and superalloys

Repeatable Performance: Ideal for production lines or high-precision thread applications

Extended Tool Life: Premium carbide + coating means more parts per tool

Usage Recommendation

Use with CNC helical interpolation cycles for stable, consistent threading

Match tool diameter to pitch to ensure full-profile thread without interference

Apply high-pressure coolant in deep hole or difficult material applications

Choose coatings based on material abrasiveness, thermal conductivity, and chip behavior

For blind holes, ensure sufficient tool clearance behind cutting edge

Technical Specifications (Customizable)

| UNS | UNC | UNF | tpi | d1/mm | L1/mm | D/mm | L/mm | F |

|---|---|---|---|---|---|---|---|---|

| UNC8-32 | 32 | 3.2 | 11 | 4 | 50 | 3 | ||

| UNC10-32 | 32 | 3.8 | 10 | 4 | 50 | 3 | ||

| UNC6-32 | 32 | 2.56 | 8 | 4 | 50 | 3 | ||

| UNC10-24 | 24 | 3.6 | 11 | 4 | 50 | 3 | ||

| UNC4-40 | 40 | 2.13 | 7 | 4 | 50 | 3 | ||

| UNC2-56 | 56 | 1.65 | 6 | 4 | 50 | 3 | ||

| UNC1/4-20 | 20 | 4.9 | 13 | 6 | 50 | 3 | ||

| UNC5/16-18 | 18 | 6 | 17 | 6 | 60 | 3 | ||

| UNF1/4-28 | 28 | 4.6 | 15 | 6 | 50 | 3 | ||

| UNS10-48 | 48 | 4.1 | 12 | 6 | 50 | 3 | ||

| UNF5/16-24 | 24 | 5.9 | 17 | 6 | 60 | 3 | ||

| UNC3/8-16 | 16 | 7.65 | 20 | 8 | 65 | 3 | ||

| UNC7/16-14 | 14 | 7.6 | 23.6 | 8 | 60 | 4 | ||

| UNF5/16-24 | 24 | 6.88 | 21 | 8 | 65 | 3 | ||

| UNF5/8-18 | 18 | 7.95 | 20 | 8 | 65 | 4 | ||

| UNF3/8-32 | 32 | 7.9 | 20 | 8 | 65 | 4 | ||

| UNF3/8-24 | 24 | 7.4 | 20 | 8 | 65 | 4 | ||

| UNF7/16-28 | 28 | 7.9 | 20 | 8 | 60 | 4 | ||

| UNF1/2-20 | 20 | 9.9 | 25 | 10 | 75 | 4 | ||

| UNF9/16-18 | 18 | 10 | 30 | 10 | 75 | 4 | ||

| UNF7/16-20 | 20 | 8.5 | 23 | 10 | 75 | 4 | ||

| UNF3/4-20 | 20 | 9.95 | 25 | 10 | 75 | 4 | ||

| UNC1/2-13 | 13 | 9.5 | 25 | 10 | 75 | 4 | ||

| UNF9/16-24 | 24 | 11.9 | 30 | 12 | 75 | 4 | ||

| UNC5/8-11 | 11 | 11.95 | 35 | 12 | 83 | 4 | ||

| UNF9/16-18 | 18 | 11.95 | 30 | 12 | 83 | 4 | ||

| UNF7/8-14 | 14 | 12 | 30 | 12 | 75 | 4 | ||

| UNC9/16-12 | 12 | 11.8 | 28.6 | 12 | 75 | 4 | ||

| UNC3/4-20 | 20 | 11.9 | 30 | 12 | 75 | 4 | ||

| UNF7/8-28 | 28 | 12 | 30 | 12 | 75 | 4 | ||

| UNF3/4-16 | 16 | 12 | 28 | 12 | 75 | 4 | ||

| UNC3/4-10 | 10 | 14.5 | 40 | 16 | 100 | 5 | ||

| UNC7/8-9 | 9 | 15.95 | 45 | 16 | 100 | 4 | ||

| UNF3/4-16 | 16 | 15.9 | 40 | 16 | 100 | 5 | ||

| UNF7/8-14 | 14 | 15.9 | 40 | 16 | 100 | 5 | ||

| UNF1-12 | 12 | 16 | 40 | 16 | 100 | 5 | ||

| UNC1-8 | 8 | 16 | 40 | 16 | 100 | 5 | ||

| UNC1-8 | 8 | 19.95 | 50 | 20 | 100 | 5 |

Get in Touch

We will provide you with feedback within 24 hours.