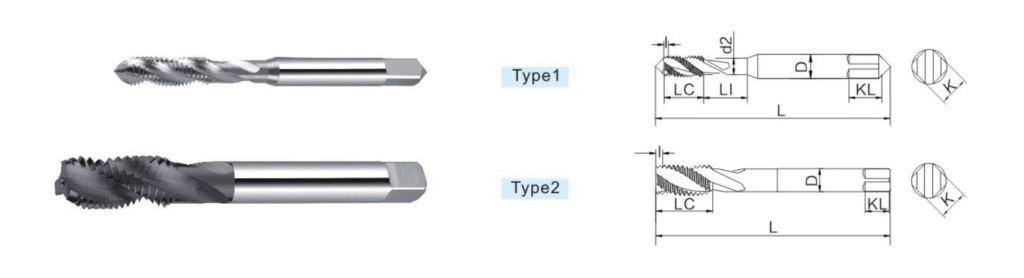

UNC/UNF Solid Carbide Spiral Flute Tap

High-Efficiency Threading for Blind Holes in Tough Materials

Product Overview

Our solid carbide spiral flute taps with Unified thread profiles (UNC/UNF) are purpose-built for blind hole threading in materials that are tough, ductile, or require superior chip evacuation. With a left-hand spiral design, these taps lift chips upward and out of the hole, ensuring smooth, burr-free thread formation and reduced tap breakage. Ideal for use in precision CNC operations, especially in aluminum, stainless steel, carbon steel, and non-ferrous alloys.

Crafted from ultra-fine grain tungsten carbide, these taps offer maximum tool life, edge stability, and thermal resistance, making them ideal for high-speed tapping environments with demanding thread quality requirements.

Key Features

Thread Standard: Unified threads – UNC (coarse) and UNF (fine)

Spiral Flute Design: Optimized for blind holes and efficient chip evacuation

Solid Carbide Substrate: Ensures high rigidity, minimal deflection, and long wear life

Sharp Cutting Edges: Precision-ground flutes enable clean and consistent threads

Excellent Performance in Ductile Materials: Ideal for aluminum, brass, stainless steel, and carbon steel

Applications

Threading blind holes in aerospace, automotive, medical device, and electronic component manufacturing

Tapping in CNC machining centers or automated production lines

Suited for aluminum alloys, mild steel, alloy steel, and non-ferrous metals

High-reliability threading in parts that require uniform thread depth and finish

Advantages

Superior chip evacuation reduces tap breakage in deep blind holes

Clean, precise threads even in sticky or soft metals like aluminum

Performs exceptionally in high-speed and dry cutting environments

Stable thread profile with less torque variation during tapping

Available in both standard sizes and custom geometries upon request

Usage Recommendations

Ensure correct pilot hole diameter and drilling depth

Use lubrication (cutting oil or MQL) to reduce friction and extend tool life

Ideal for use with rigid tapping cycles on CNC machinery

Avoid in extremely abrasive or brittle materials — consider straight flute for those cases

Technical Specifications (Customizable)

| Thread | Prec. | l | L | LC | D | Z | A | LK | K |

| NO.2-56UNC | 2B/3B | 1.5P | 42 | 11 | 3 | 2 | 30 | 5 | 2.5 |

| NO.2-64UNF | 2B/3B | 1.5P | 42 | 11 | 3 | 2 | 30 | 5 | 2.5 |

| NO.3-48UNC | 2B/3B | 1.5P | 42 | 12 | 3 | 2 | 30 | 5 | 2.5 |

| NO.3-56UNF | 2B/3B | 1.5P | 42 | 12 | 3 | 2 | 30 | 5 | 2.5 |

| NO.4-40UNC | 2B/3B | 1.5P | 52 | 12 | 3 | 3 | 30 | 5 | 2.5 |

| NO.4-48UNF | 2B/3B | 1.5P | 52 | 12 | 3 | 3 | 30 | 5 | 2.5 |

| NO.5-40UNC | 2B/3B | 1.5P | 52 | 12 | 4 | 3 | 30 | 6 | 3.2 |

| NO.5-44UNF | 2B/3B | 1.5P | 52 | 12 | 4 | 3 | 30 | 6 | 3.2 |

| NO.6-32UNC | 2B/3B | 1.5P | 52 | 13 | 4 | 3 | 30 | 6 | 3.2 |

| NO.6-40UNF | 2B/3B | 1.5P | 52 | 13 | 4 | 3 | 30 | 6 | 3.2 |

| NO.8-32UNC | 2B/3B | 1.5P | 55 | 13 | 5 | 3 | 30 | 6 | 4 |

| NO.8-36UNF | 2B/3B | 1.5P | 55 | 13 | 5 | 3 | 30 | 6 | 4 |

| NO.10-24UNC | 2B/3B | 1.5P | 60 | 15 | 5 | 3 | 30 | 6 | 4 |

| NO.10-32UNF | 2B/3B | 1.5P | 60 | 15 | 5 | 3 | 30 | 6 | 4 |

| NO.12-24UNC | 2B/3B | 2.5P | 65 | 15 | 6 | 3 | 30 | 7 | 4.5 |

| NO.12-28UNF | 2B/3B | 2.5P | 65 | 15 | 6 | 3 | 30 | 7 | 4.5 |

| 1/4-20UNC | 2B/3B | 2.5P | 65 | 17 | 6 | 3 | 30 | 7 | 4.5 |

| 1/4-28UNF | 2B/3B | 2.5P | 65 | 17 | 6 | 3 | 30 | 7 | 4.5 |

| 5/16-18UNC | 2B/3B | 2.5P | 72 | 20 | 6.1 | 3 | 30 | 8 | 5 |

| 5/16-24UNF | 2B/3B | 2.5P | 72 | 20 | 6.1 | 3 | 30 | 8 | 5 |

| 3/8-16UNC | 2B/3B | 2.5P | 75 | 22 | 7 | 3 | 30 | 8 | 5.5 |

| 3/8-24UNF | 2B/3B | 2.5P | 75 | 22 | 7 | 3 | 30 | 8 | 5.5 |

| 7/16-14UNC | 2B/3B | 2.5P | 83 | 25 | 8 | 3 | 30 | 9 | 6 |

| 7/16-20UNF | 2B/3B | 2.5P | 83 | 25 | 8 | 3 | 30 | 9 | 6 |

| 1/2-13UNC | 2B/3B | 2.5P | 90 | 25 | 9 | 4 | 15 | 10 | 7 |

| 1/2-20UNF | 2B/3B | 2.5P | 90 | 25 | 9 | 4 | 15 | 10 | 7 |

Get in Touch

We will provide you with feedback within 24 hours.