UNC/UNF Solid Carbide Straight Flute Tap

Precision Tapping for Tough & Brittle Materials

Product Overview

Our solid carbide straight flute taps with UNC and UNF threads are engineered for precision internal threading in brittle, abrasive, or hard materials, such as cast iron, non-ferrous metals, plastics, and composites. These taps are manufactured from ultra-fine grain tungsten carbide, offering superior hardness, thermal resistance, and edge stability — ideal for CNC machining and rigid tapping.

Designed with straight flutes, this tap ensures controlled chip flow and clean thread cutting, especially effective in short chipping materials or when tapping through holes.

Key Features

Thread Type: Unified Inch Standards – UNC (coarse) & UNF (fine) threads

Solid Carbide Material: Ultra-hard, wear-resistant, and long-lasting

Straight Flute Geometry: Ideal for through holes and short-chipping materials

Thread Class: 2B / 3B internal thread tolerance (precision tapping)

Rigid Tapping Ready: Perfect for CNC machining centers and automated production

Applications

Tapping cast iron, aluminum alloys, copper, brass, and engineering plastics

Used in aerospace, automotive, electronics, mold making, and precision machining

Ideal for through holes or shallow blind holes in abrasive or brittle materials

Recommended for high-speed tapping with minimal chip interference

Advantages

High wear resistance in abrasive or tough-to-machine materials

Produces accurate, consistent thread profiles with minimal burr

No chip clogging in short chipping or brittle materials

Excellent for automated high-speed production lines

Reduced tap breakage risk due to superior rigidity and edge sharpness

Usage Recommendations

Use cutting fluid or mist lubrication for better finish and tap longevity

Pre-drill holes to the recommended minor diameter for best thread quality

Avoid using on ductile materials that generate long chips – consider spiral taps instead

Ideal for rigid tapping mode on CNC or high-precision machines

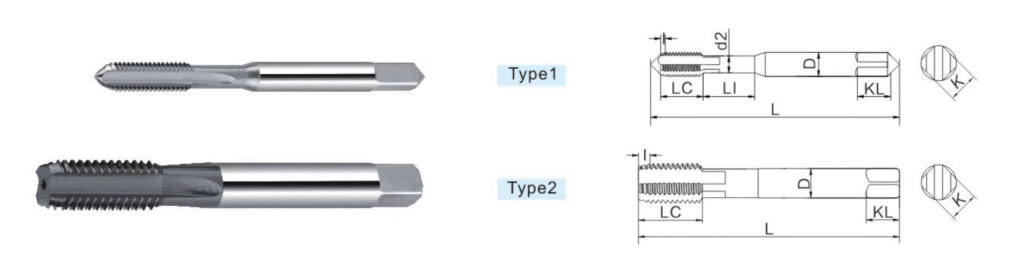

Technical Specifications (Customizable)

| Thread | Prec. | l | L | LC | D | Z | LK | K |

| NO.2-56UNC | 2B/3B | 1.5P | 42 | 11 | 3 | 3 | 5 | 2.5 |

| NO.2-64UNF | 2B/3B | 1.5P | 42 | 11 | 3 | 3 | 5 | 2.5 |

| NO.3-48UNC | 2B/3B | 1.5P | 42 | 12 | 3 | 3 | 5 | 2.5 |

| NO.3-56UNF | 2B/3B | 1.5P | 42 | 12 | 3 | 3 | 5 | 2.5 |

| NO.4-40UNC | 2B/3B | 1.5P | 52 | 12 | 3 | 3 | 5 | 2.5 |

| NO.4-48UNF | 2B/3B | 1.5P | 52 | 12 | 3 | 3 | 5 | 2.5 |

| NO.5-40UNC | 2B/3B | 1.5P | 52 | 12 | 4 | 3 | 6 | 3.2 |

| NO.5-44UNF | 2B/3B | 1.5P | 52 | 12 | 4 | 3 | 6 | 3.2 |

| NO.6-32UNC | 2B/3B | 1.5P | 52 | 13 | 4 | 3 | 6 | 3.2 |

| NO.6-40UNF | 2B/3B | 1.5P | 52 | 13 | 4 | 3 | 6 | 3.2 |

| NO.8-32UNC | 2B/3B | 1.5P | 55 | 13 | 5 | 3 | 6 | 4 |

| NO.8-36UNF | 2B/3B | 1.5P | 55 | 13 | 5 | 3 | 6 | 4 |

| NO.10-24UNC | 2B/3B | 1.5P | 60 | 15 | 5 | 3 | 6 | 4 |

| NO.10-32UNF | 2B/3B | 1.5P | 60 | 15 | 5 | 3 | 6 | 4 |

| NO.12-24UNC | 2B/3B | 2.5P | 65 | 15 | 6 | 3 | 7 | 4.5 |

| NO.12-28UNF | 2B/3B | 2.5P | 65 | 15 | 6 | 3 | 7 | 4.5 |

| 1/4-20UNC | 2B/3B | 2.5P | 65 | 17 | 6 | 3 | 7 | 4.5 |

| 1/4-28UNF | 2B/3B | 2.5P | 65 | 17 | 6 | 3 | 7 | 4.5 |

| 5/16-18UNC | 2B/3B | 2.5P | 72 | 20 | 6.1 | 4 | 8 | 5 |

| 5/16-24UNF | 2B/3B | 2.5P | 72 | 20 | 6.1 | 4 | 8 | 5 |

| 3/8-16UNC | 2B/3B | 2.5P | 75 | 22 | 7 | 4 | 8 | 5.5 |

| 3/8-24UNF | 2B/3B | 2.5P | 75 | 22 | 7 | 4 | 8 | 5.5 |

| 7/16-14UNC | 2B/3B | 2.5P | 83 | 25 | 8 | 4 | 9 | 6 |

| 7/16-20UNF | 2B/3B | 2.5P | 83 | 25 | 8 | 4 | 9 | 6 |

| 1/2-13UNC | 2B/3B | 2.5P | 90 | 25 | 9 | 4 | 10 | 7 |

| 1/2-20UNF | 2B/3B | 2.5P | 90 | 25 | 9 | 4 | 10 | 7 |

Get in Touch

We will provide you with feedback within 24 hours.