- 2025-01-26

- 0 Comment

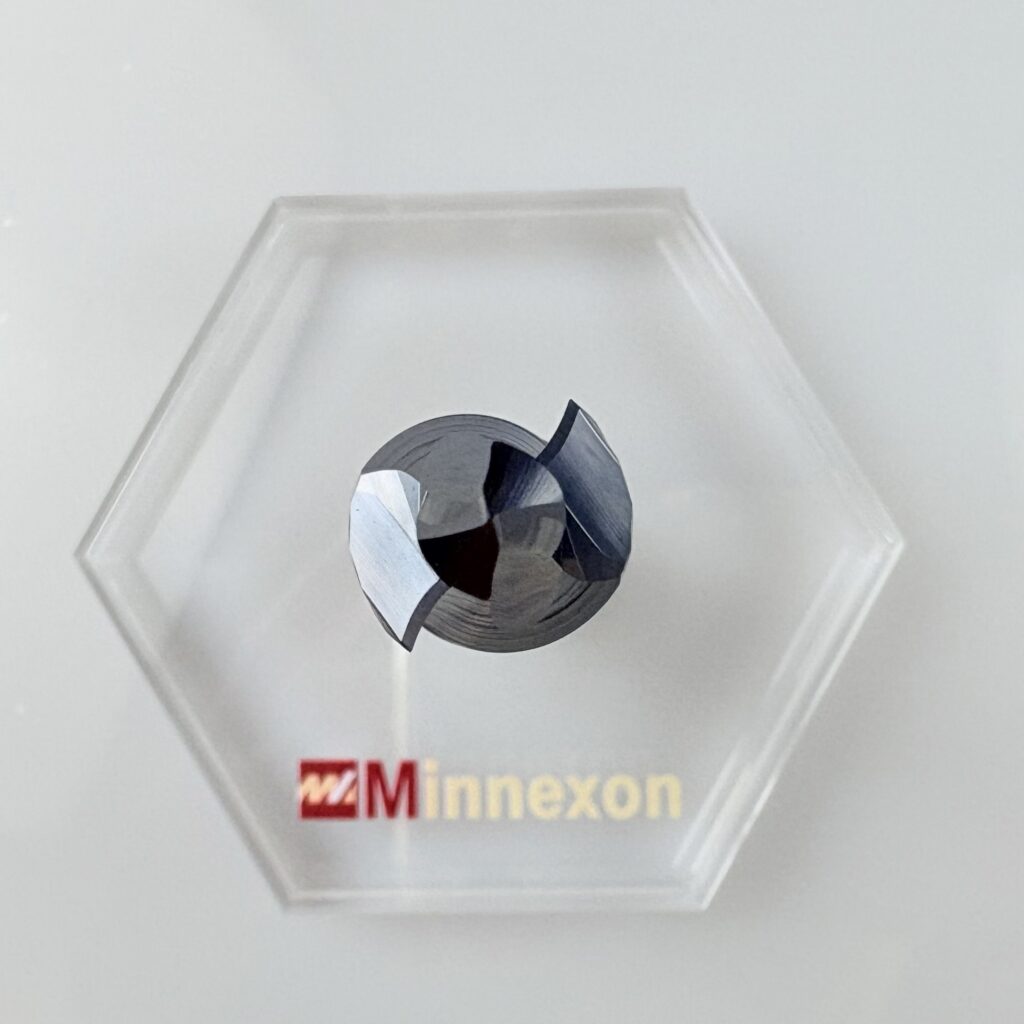

Step Drills: The Ultimate Tool for Efficient Hole Making in Thin Sheet Metal

When it comes to drilling relatively thin materials like sheet metal, plastics, and composites, step drills are the go-to solution. Despite their widespread use in industries such as automotive, electrical, and HVAC, many manufacturers in North America and Europe are still unfamiliar with the tool’s full potential. In this article, we will explore what step drills are, why they are perfect for drilling thin to moderately thick materials, and how they can improve the drilling process for manufacturers worldwide. At Minnexon, a leading manufacturer of cemented carbide tools, we specialize in providing high-performance solutions like step drills for industries across the globe.

What Is a Step Drill?

A step drill is a specialized drill bit designed to create multiple hole sizes with a single tool. It features a stepped design, where each “step” gradually increases in diameter, allowing the user to drill several different hole sizes without changing tools. Step drills are commonly used to drill holes in thin to moderately thick materials, including sheet metal, plastics, aluminum, and composite materials.

Key Features of a Step Drill

Multiple Sizes in One Tool: Drill several hole diameters with a single tool, saving time by eliminating the need to change bits.

Conical Shape: The gradual increase in size with each step makes it perfect for drilling multiple hole sizes in a single material.

High-Speed Drilling: Step drills allow for faster drilling in thin to moderately thick materials, making them highly efficient in production environments.

Centering Point: Most step drills feature a pointed tip to help keep the drill bit centered while starting the hole, ensuring precision.

Why Step Drills Are Perfect for Relatively Thin Materials

Step drills excel when drilling relatively thin materials like thin sheet metal (e.g., 1mm to 6mm thickness), plastics, and aluminum. They are specifically designed to avoid issues such as material deformation, burr formation, and misalignment, which are common when drilling thin materials with traditional drill bits.

Advantages of Step Drills for Thin and Moderate Thickness Materials

Efficient Multi-Size Drilling: Step drills allow you to drill different sizes of holes with a single tool, greatly increasing productivity and reducing setup time.

Clean Hole Edges: The gradual increase in hole size reduces burrs, resulting in clean, smooth holes that require less finishing work.

Faster Cycle Times: Step drills are ideal for mass production, as they offer faster drilling speeds compared to standard drills for small to medium-sized holes.

No Tool Changes: You can drill multiple hole sizes without switching between different drill bits, making the process more streamlined and efficient.

Step Drills vs. Twist Drills: Why Step Drills Are a Better Option for Multiple Hole Sizes

While twist drills are commonly used in various machining applications, they are not suitable for drilling multiple hole sizes in thin materials. A standard twist drill creates only one hole diameter per tool, meaning you need to change the drill bit each time you want to drill a different size. This can slow down the process and increase downtime.

On the other hand, a step drill allows you to drill several different-sized holes with one tool, improving efficiency. Additionally, the step drill’s design is more forgiving when working with thin materials, as it reduces the chance of material distortion, chip buildup, and overheating.

At Minnexon, we specialize in manufacturing high-quality cemented carbide tools, including step drills, that are designed for superior performance, efficiency, and durability in a wide range of industries.

Why Step Drills Are Gaining Popularity

While step drills have been a staple tool in industries across Asia for years, they are increasingly gaining recognition in North America and Europe. In the past, many manufacturers in the West favored traditional drilling tools like twist drills and center drills, which led to slower adoption of step drills. However, as manufacturing processes become more streamlined and the demand for higher efficiency increases, step drills are starting to become more commonplace in Western industries.

The growing awareness of their advantages, such as multi-size drilling, cost reduction, and improved hole quality, is driving their adoption. The misconception that step drills are only suitable for very thin materials or niche applications is being debunked as more manufacturers experience the tool’s versatility across a range of materials and applications.

Key Benefits of Step Drills for Manufacturers

Step drills are especially beneficial for manufacturers who need to optimize their drilling operations and enhance productivity. Here are some key benefits:

Increased Efficiency: Step drills allow for the drilling of multiple hole sizes with a single tool. This eliminates the need for frequent tool changes, significantly reducing cycle times and improving operational efficiency.

Cost-Effective: Since step drills can perform multiple tasks, manufacturers reduce the need for different drill bits, which in turn lowers overall tool costs and the frequency of tool replacements.

Better Hole Quality: Step drills create smooth, clean holes with minimal burrs. This is especially important in industries like automotive and electronics, where high-quality finishes are essential, and post-processing costs need to be minimized.

Versatility Across Materials: Step drills are highly versatile and can be used on a variety of materials, from sheet metal and plastics to composite materials. This adaptability makes them ideal for many sectors, including automotive, HVAC, electronics, and prototyping.

Industries That Benefit Most from Step Drills

Step drills are ideal for industries where high precision, fast turnaround, and clean hole creation are crucial. Here are some key sectors that benefit the most:

Automotive Manufacturing: Step drills are used to drill precise holes in thin metal components, such as car body parts, brackets, and frames.

Electrical Industry: Used to make holes in electrical panels, enclosures, and wiring components, where a variety of hole sizes are required quickly.

HVAC: Step drills are highly effective for drilling holes in air ducts, ventilation systems, and sheet metal, where accuracy and speed are key.

Prototyping and Custom Part Manufacturing: For manufacturers involved in custom part production or rapid prototyping, step drills are ideal for creating a range of hole sizes in a single operation, especially for low-volume production runs.

The Rising Importance of Step Drills in Efficient Hole Making

In conclusion, step drills offer several key advantages that make them indispensable in modern manufacturing, especially for industries requiring high-speed, high-precision hole making. By drilling multiple hole sizes with a single tool, step drills save time, reduce tool costs, and improve hole quality. They are ideal for applications in sheet metal, plastics, and composite materials, among others.

As manufacturers in the West continue to explore ways to improve their processes, step drills present a valuable opportunity for companies seeking efficiency and cost savings. At Minnexon, we are proud to supply top-quality cemented carbide tools, including step drills, to industries worldwide, helping them achieve better results in less time.